Electrocatalytic hydrogen-production material and preparation method thereof

An electrocatalysis, molybdenum disulfide technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of slow electron transfer rate, small load, poor electrode stability, etc., to achieve improved hydrogen production activity, good application prospects, The effect of good electrocatalytic hydrogen production activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: This example prepares a high-abundance single-atom cobalt-modified molybdenum sulfide composite material, which specifically includes the following steps:

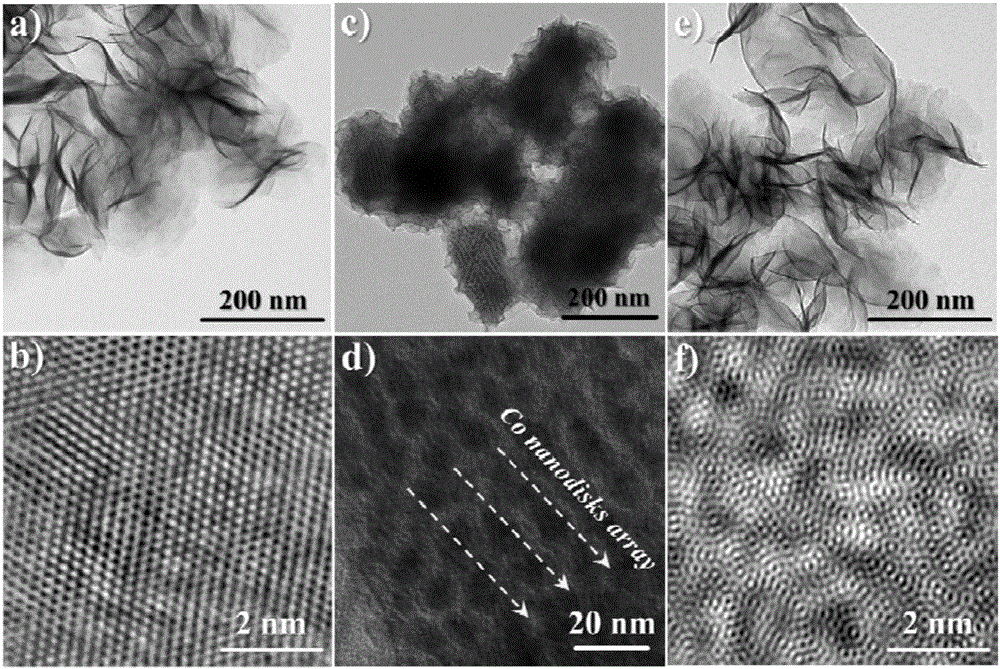

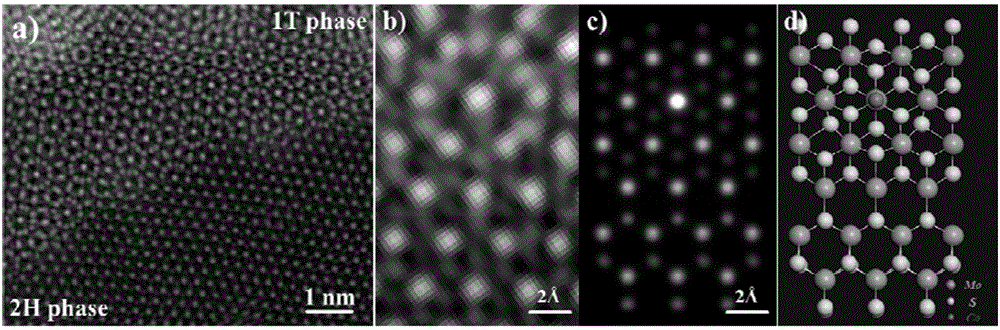

[0016] (1) 1.236g of ammonium heptamolybdate tetrahydrate and 2.284g of thiourea were dissolved in 25mL of deionized water (the molybdenum-sulfur ratio of the precursor was 7:30), and transferred to a polytetrafluoroethylene liner with a volume of 40mL, After sealing, it was placed in a stainless steel autoclave and reacted at 220° C. for 18 hours, and cooled naturally to room temperature. The product was washed three times with absolute ethanol and water, and dried in vacuum at 60°C to obtain molybdenum sulfide sheets, such as figure 1 a-1b, from figure 1 It can be seen from a-1b that when the cobalt nanosheets are not loaded, the surface of the molybdenum disulfide nanosheets presents an obvious regular 2H structure;

[0017] (2) Dissolve 0.54g dicobalt octacarbonyl in 3mL anhydrous o-dichlorobenzene ...

Embodiment 2

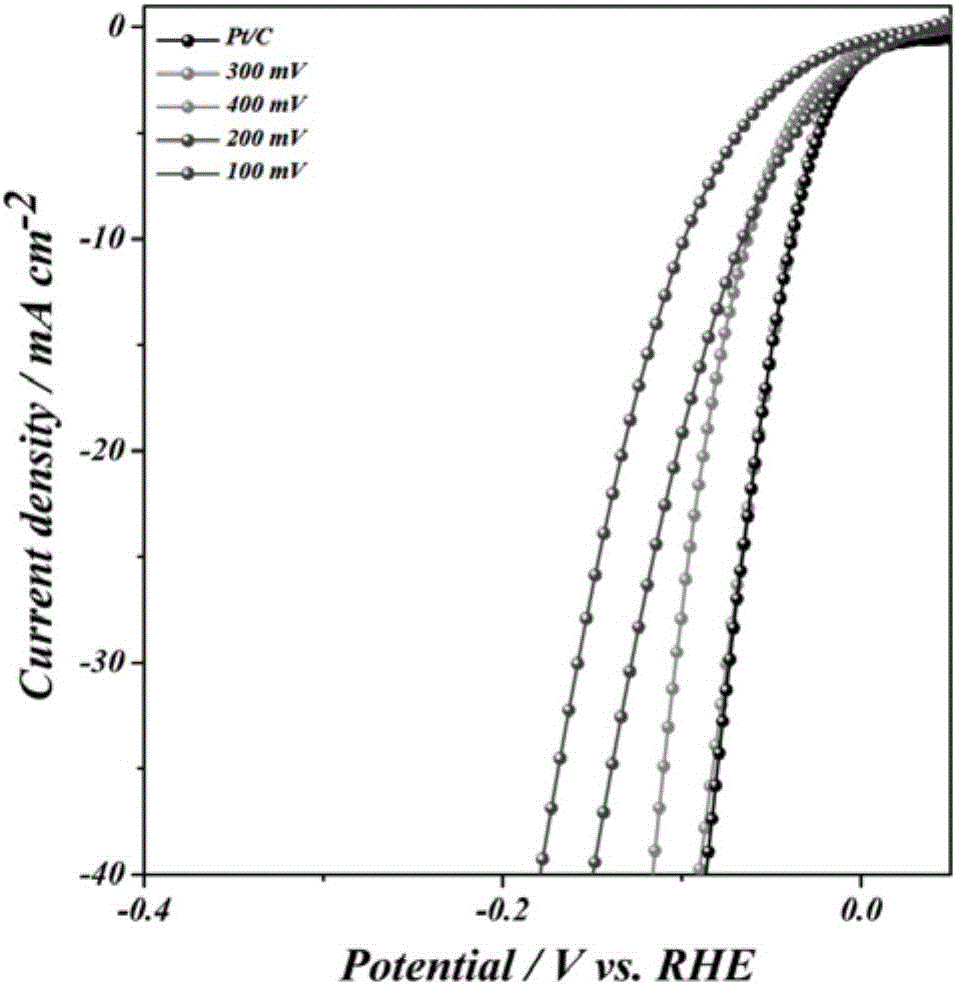

[0021] Example 2, this implementation prepares the molybdenum disulfide layered structure modified by cobalt nanosheets according to the steps 1-3 in Example 1, and then the prepared cobalt nanosheets modified molybdenum disulfide layered structure is subjected to the following treatment :

[0022] Drop the ethanol solution of the molybdenum disulfide layered structure modified by cobalt nanosheets onto the surface of the glassy carbon electrode, use the treated glassy carbon electrode as the cathode, use the platinum sheet as the anode, and use 0.5mol / L sulfuric acid solution as the electrolyte , electrochemical scanning was carried out under the constant overpotential shown in Table 1 for 1 hour, and then the glassy carbon electrode was subjected to ultrasound, and the product obtained by ultrasound was dissolved in 1 mL ethanol solution to obtain the iso New electrocatalytic hydrogen production materials A-D with solid structure.

[0023] Table 1

[0024] Consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com