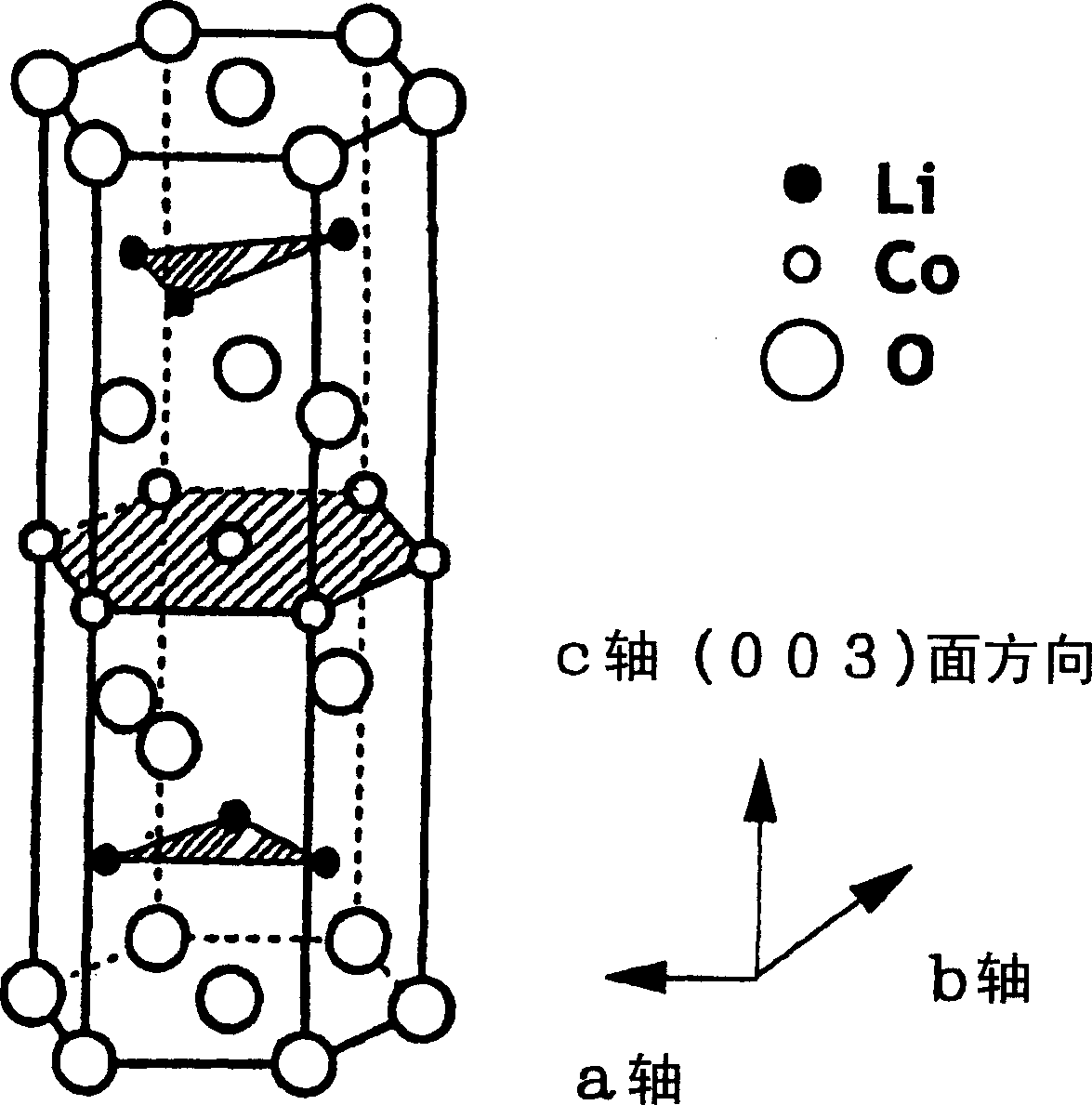

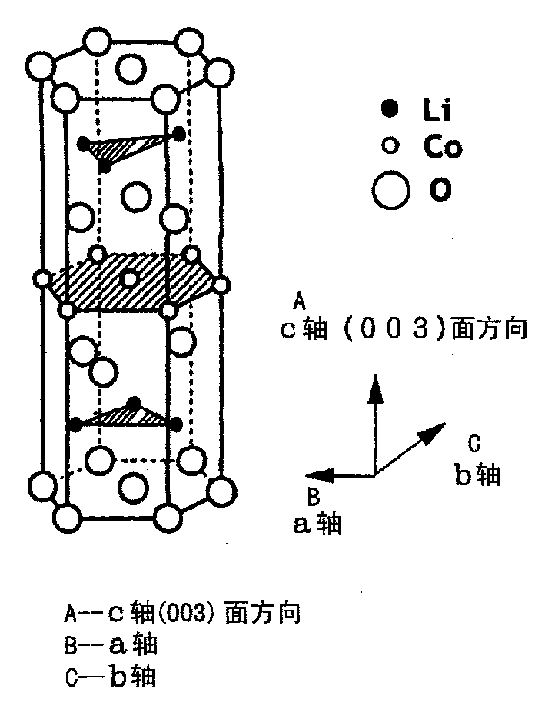

Lithium secondary cell and positive electrode active material, positive plate, and method for manufacturing them

A cathode active material, lithium battery technology, applied in active material electrodes, electrode manufacturing, chemical electrode manufacturing, etc., can solve the problems of insufficient cycle characteristics, cycle characteristics, and low temperature characteristics of delay characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

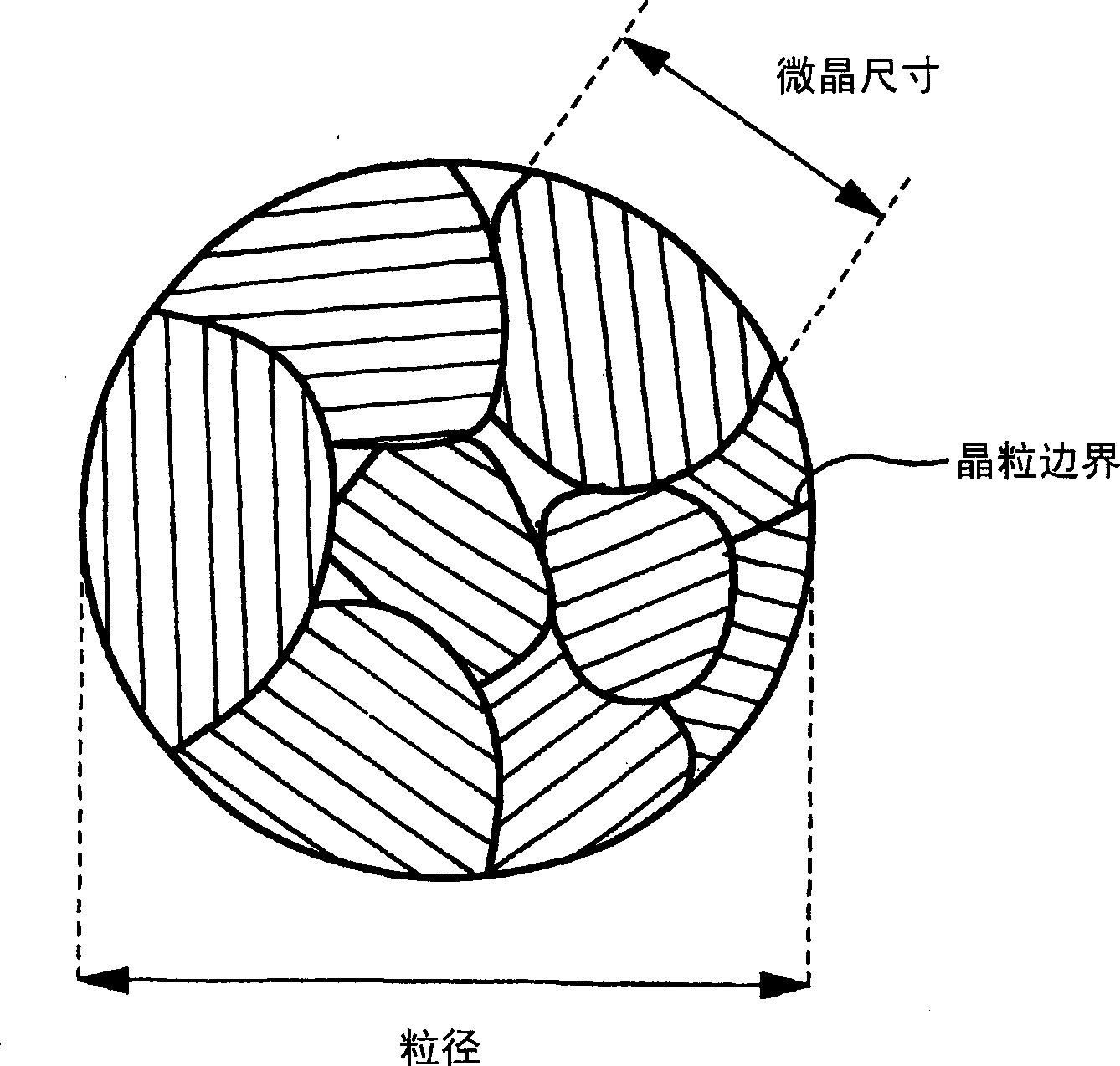

[0165] Relative Co 3 o 4 100 parts by weight, evenly mixed with Li 2 CO 3 46.5 parts by weight, sintered at about 980°C for 10 hours, the obtained bulk LiCoO 2 Pulverization and classification yielded granular materials with an average particle diameter of 20 μm. Next, heat treatment was performed at 500° C. for 10 hours in the air, and granular materials having the crystal sizes and coordination numbers shown in Table 1 were obtained.

Embodiment 2

[0167] Except relative Co 3 o 4 100 parts by weight, mixed with Li 2 CO 3 Except for 46 parts by weight, granular materials having crystal sizes and coordination numbers shown in Table 1 were obtained in the same manner as in Example 1.

Embodiment 3

[0169] Except that the heat treatment time was 5 hours, granular materials having the crystal sizes and coordination numbers shown in Table 1 were obtained in the same manner as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com