Device for recovering viscose fiber production exhaust-gas with soda washing-adsorption condensing method

A technology of viscose fiber and alkali washing, applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve problems such as poor waste gas treatment effect, difficult discharge standards, and complicated waste gas treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

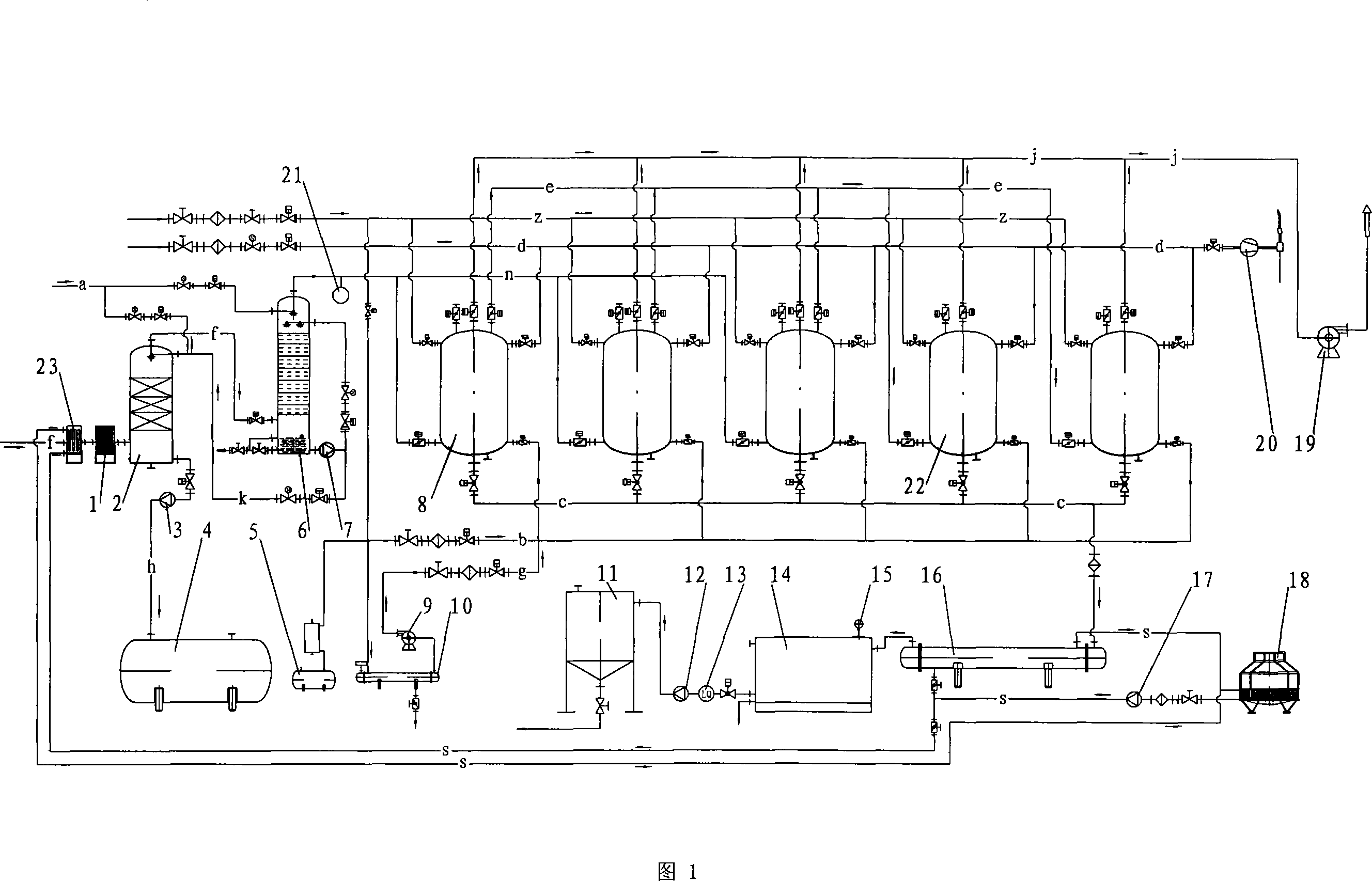

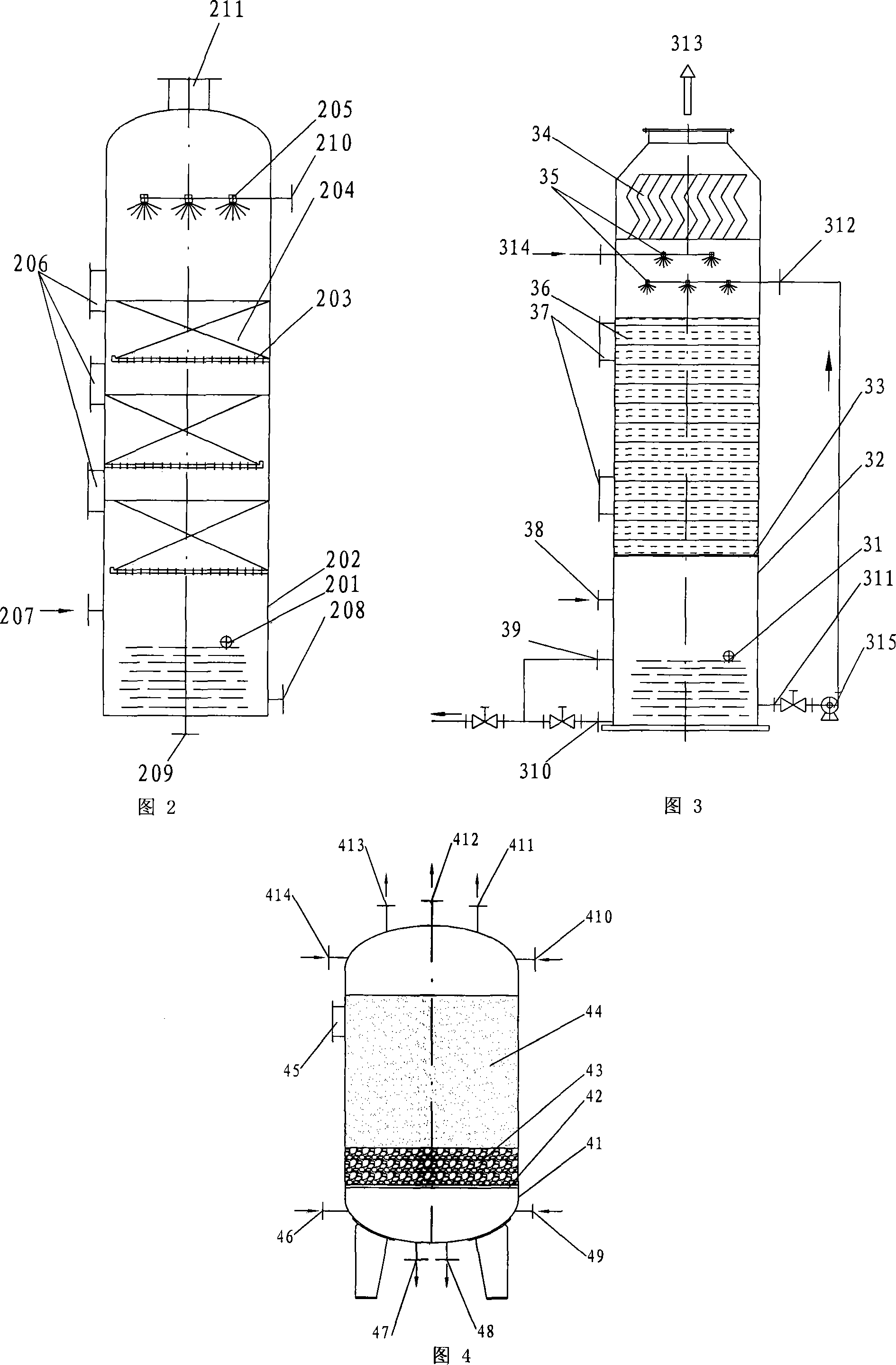

[0021] 1 to 4, the present invention is provided with a waste gas filter 1, an alkali washing tower 2, a solution delivery pump 3, a sodium hydrosulfide storage tank 4, an air compressor 5, a washing tower 6, a circulating pump 7, an adsorption tank 8, a heat Fan 9, heater 10, carbon disulfide storage tank 11, gear infusion pump 12, flow meter 13, solution separator 14, maglev ball liquid level switch 15, condenser 16, water pump 17, cooling tower 18, induced draft fan 19, vacuum pump 20 , H 2 S and CS 2 Concentration analyzer 21, adsorption tank 22, cooler 23, differential pressure gauge, flow analyzer, pneumatic ball valve, pipeline, etc. The input end of the cooler 22 is externally connected to H 2 S, CS 2 Exhaust gas, the outlet of the cooler 22 is connected to the air inlet of the filter 1, the air outlet of the filter 1 is connected to the air inlet of the alkali scrubbing tower 2, and the air outlet located at the top of the alkali scrubbing tower 2 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com