High molecular heavy metal chelating flocculant and preparation method thereof

A heavy metal and polymer technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc., to achieve the effects of easy operation and control, high yield, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

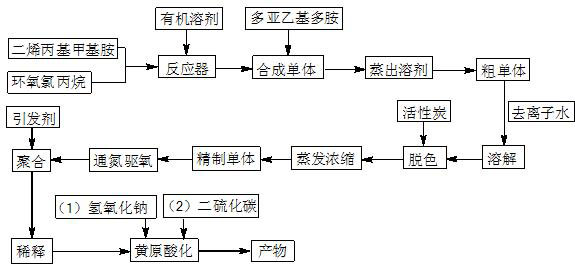

Method used

Image

Examples

Embodiment 1

[0033] (1) According to the molar ratio of diallylmethylamine and epichlorohydrin as 1:1, respectively add 29.2mL diallylmethylamine and 15.8mL epichlorohydrin into the Add 300mL tetrahydrofuran to a 500mL three-neck flask with a reflux condenser and a mechanical stirrer, stir evenly, and heat up to 60°C for 10h;

[0034] (2) Add 21.9mL of diethylenetriamine dropwise, continue the reaction at 60°C for 6h, then distill off the solvent tetrahydrofuran to obtain 63.7g of crude monomer (pale yellow paste);

[0035] (3) Add 575mL of deionized water to dissolve the paste obtained in step (2) to form a solution with a mass percentage concentration of 10%, add activated carbon for decolorization, and then filter, and the filtrate is concentrated to a monomer mass percentage concentration by evaporation under reduced pressure Reach 60%, get refined monomer solution; Then pass N 2 Drive oxygen for 30 minutes, heat up to 60°C, add 712 mg of ammonium persulfate, react for 9 hours, and ob...

Embodiment 2

[0038] (1) According to the molar ratio of diallylmethylamine and epichlorohydrin as 1:1.02, respectively add 29.2mL of purified diallylmethylamine and 16.2mL of epichlorohydrin to the In the 1000mL three-neck flask with funnel, reflux condenser and mechanical stirrer, add 450mL tetrahydrofuran and stir evenly, heat up to 65°C and react for 9h;

[0039] (2) Add 29.9 mL of triethylenetetramine dropwise to the solution in step (1) and continue the reaction at 65°C for 5 hours, then distill off the solvent tetrahydrofuran to obtain 73.1 g of crude monomer (light yellow paste);

[0040] (3) Add 658mL of deionized water to dissolve the paste obtained in step (2) to form a solution with a mass percent concentration of 10%, add activated carbon for decolorization, and then filter, and the filtrate is concentrated to a monomer mass percent concentration by evaporation under reduced pressure Reach 65%, get refined monomer solution; Then pass N 2 Drive oxygen for 30 minutes, raise the ...

Embodiment 3

[0043] (1) According to the molar ratio of diallylmethylamine and epichlorohydrin as 1:1.05, respectively add 29.2mL of purified diallylmethylamine and 16.7mL of epichlorohydrin to the Into a 1000mL three-necked flask with a funnel, a reflux condenser and a mechanical stirrer, add 600mL of tetrahydrofuran, stir evenly, and heat up to 70°C for 9 hours;

[0044] (2) Add 38.4 mL of tetraethylenepentamine dropwise to the solution in step (1) and continue the reaction at 70°C for 5 hours, then distill off the solvent tetrahydrofuran to obtain 81.2 g of crude monomer (pale yellow paste);

[0045] (3) Add 730mL of deionized water to dissolve the paste obtained in step (2) to form a solution with a mass percent concentration of 10%, add activated carbon for decolorization, and then filter, and the filtrate is concentrated to a monomer mass percent concentration by evaporation under reduced pressure Reach 70%, get refined monomer solution; Then pass N 2 Drive oxygen for 30 minutes, ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com