Device and method for testing performance of two-phase flow drag reducer

A test device and technology of drag reducer, which is applied in the direction of DC flow characteristic measurement, etc., can solve the problem of low drag reduction rate of drag reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

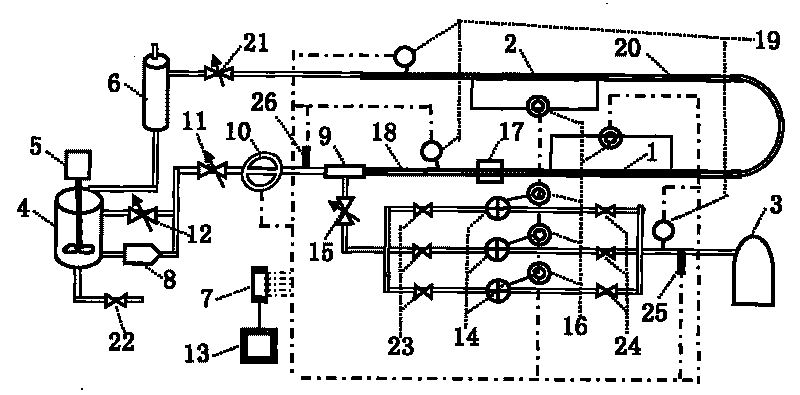

Image

Examples

Embodiment 1

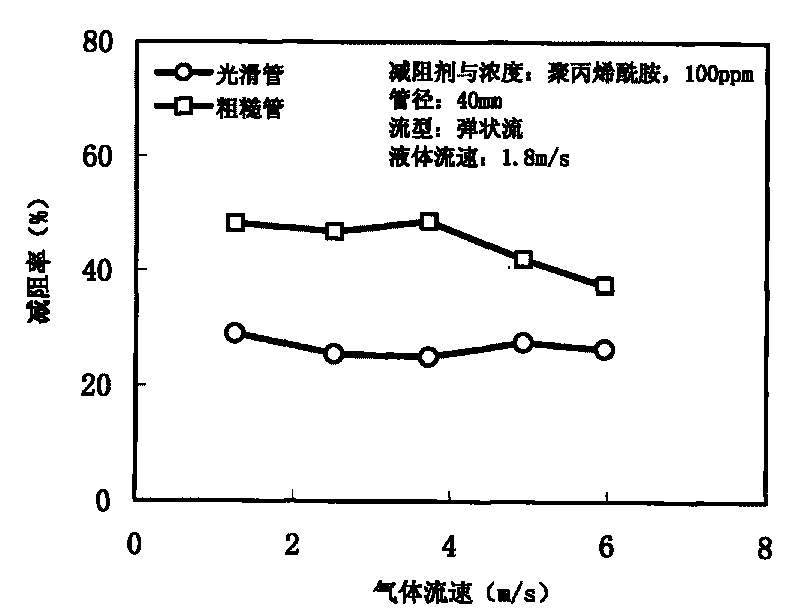

[0039] Example 1 Performance test of gas-liquid two-phase flow drag reducer

[0040] (1) Add the solvent phase of the drag reducing agent to the liquid storage container 4 first, and do not add the drag reducing agent at this time, and wait to test the frictional resistance characteristics of the two-phase flow without the drag reducing agent.

[0041] (2) Turn on the screw pump 8 and the air source 3 in sequence. Open the pressure regulating valve 21, the liquid main pipeline regulating valve 11 and the bypass regulating valve 12 in sequence, and through the joint adjustment of the liquid main pipeline regulating valve 11 and the bypass regulating valve 12, the liquid flow rate is kept within the range of 0.6-3m / s. A stable value, in this embodiment, this stable value is 1.8m / s. Select the size of the gas orifice plate according to the gas flow rate, and open the ball valves before and after the selected orifice plate. Then open the gas regulating valve 15, through the regu...

Embodiment 2

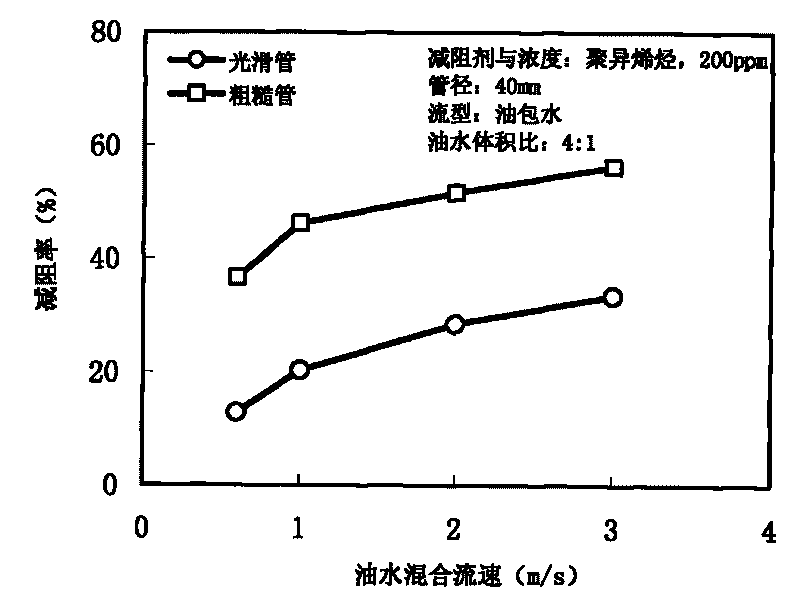

[0048] Example 2 Performance test of oil-water two-phase flow drag reducer

[0049] (1) Add oil and water in a certain proportion to the liquid storage container 4 and use the agitator 5 to fully mix the two phases of oil and water. At this time, no drag reducing agent is added. In this embodiment, the volume ratio of oil to water is 4:1.

[0050] (2) Close the ball valves 24, 15 before and after the gas regulating valve 15 and the gas orifice. Turn on the screw pump 8, open the pressure regulating valve 21, the liquid main pipeline regulating valve 11 and the bypass regulating valve 12 in sequence, and gradually change the flow rate of the oil-water mixture through the linkage regulation of the liquid main pipeline regulating valve 11 and the bypass regulating valve 12 , to test the frictional resistance of the oil-water two-phase flow in the smooth pipe test section and the rough pipe test section respectively.

[0051] (3) Obtain a set of frictional resistance data DR at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com