Natural gas pipeline drag-reducing agent and preparation method thereof

A technology for natural gas pipelines and drag reducing agents, applied in pipeline systems, chemical instruments and methods, mechanical equipment, etc., can solve the problems of no drag reduction mechanism and theoretical guidance of molecular design of drag reducers, and achieve the application value of drag reduction and the reaction Mild conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

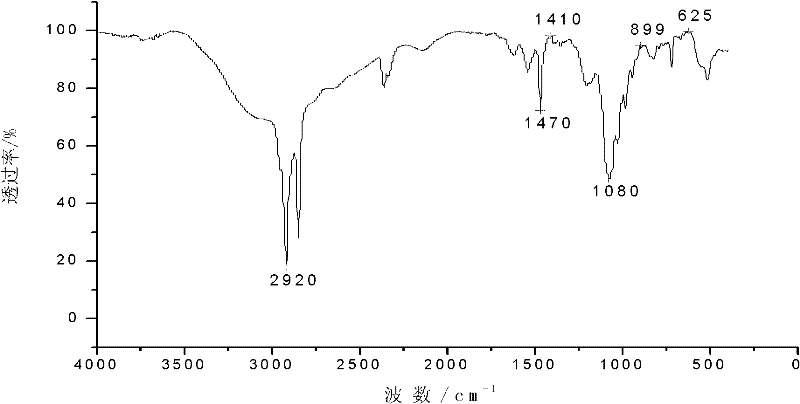

[0030] Embodiment 1, the preparation of natural gas pipeline drag reducer

[0031] Add 47.25 g of octadecyl alcohol into a three-necked flask, heat up to 60° C. for melting, then add 7.0 g of phosphorus pentoxide under rapid stirring (the molar ratio of octadecyl alcohol to phosphorus pentoxide is 3.5:1.0) , be warming up to 70 ℃, carry out esterification reaction at this temperature for 6 hours and obtain 54.25g esterification product; Then add 0.9g water in the esterification product obtained (the molar ratio of phosphorus pentoxide and water is 1.0: 1.0) , carry out hydrolysis reaction at 90 ℃ for 2 hours to obtain hydrolyzate 55.15g; then add 6.1g 2-hydroxyethylamine in the obtained hydrolyzate and carry out neutralization reaction (the mol ratio of phosphorus pentoxide and 2-hydroxyethylamine is 1.0:2.0), carry out neutralization reaction at 90°C for 1 hour, and then filter while hot to obtain 38.8g of white waxy solid, which is the drag reducer for natural gas pipelines....

Embodiment 2

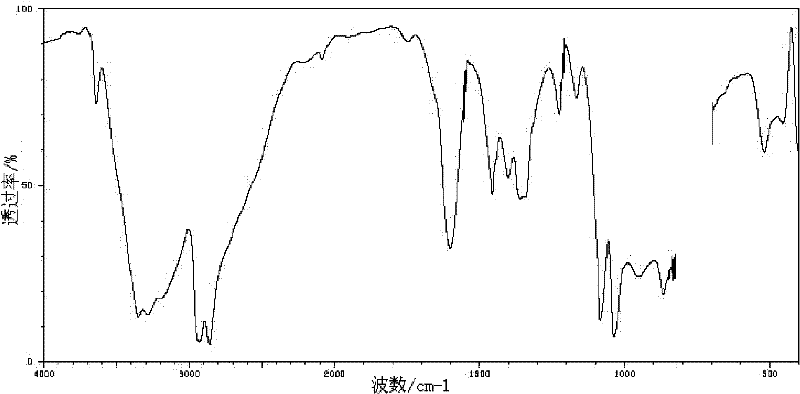

[0032] Embodiment 2, preparation of natural gas pipeline drag reducer

[0033] Add 42.40 g of cetyl alcohol into a three-necked flask, heat up to 60° C. for melting, then add 7.0 g of phosphorus pentoxide under rapid stirring (the molar ratio of cetyl alcohol to phosphorus pentoxide is 3.5:1.0) , be warming up to 80 ℃, carry out esterification reaction at this temperature for 4 hours and obtain 49.40g esterification product; Then add 0.6g water in the esterification product obtained (the molar ratio of phosphorus pentoxide and water is 1.5: 1.0) , carried out hydrolysis reaction at 80 ℃ for 2.5 hours to obtain hydrolyzate 50.30g; Then in the hydrolyzate obtained, add 10.68g 2,2'-dihydroxydiethylamine to carry out neutralization reaction (phosphorus pentoxide and 2-hydroxyethylamine The molar ratio of the amine is 1.0:3.5), and the neutralization reaction is carried out at 90° C. for 1 hour, and then filtered while hot to obtain 60.98 g of white waxy solid, which is the natural...

Embodiment 3

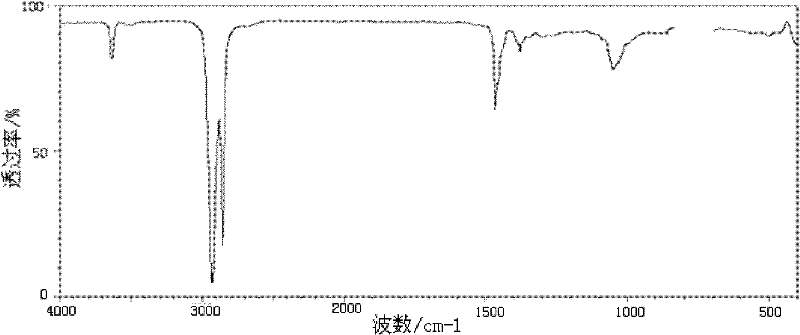

[0034] Embodiment 3, preparation of natural gas pipeline drag reducer

[0035] Add 27.70 g of dodecyl alcohol into a three-necked flask, heat up to 60° C. for melting, then add 7.0 g of phosphorus pentoxide under rapid stirring (the molar ratio of dodecyl alcohol to phosphorus pentoxide is 3.0:1.0) , be warming up to 70 ℃, carry out esterification reaction at this temperature for 6 hours and obtain 39.60g esterification product; Then add 0.9g water in the esterification product obtained (the molar ratio of phosphorus pentoxide and water is 1.0: 1.0) , carry out hydrolysis reaction at 90 ℃ for 2 hours to obtain 40.50 g of hydrolyzate; then add 12.2 g of 2,2', 2"-trihydroxytriethylamine to the obtained hydrolyzate to carry out neutralization reaction (phosphorus pentoxide and 2 -The molar ratio of hydroxyethylamine is 1.0:4.0), neutralization reaction was carried out at 80° C. for 1.5 hours, and then filtered while hot to obtain 77.6 g of white waxy solid which was the natural g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com