Corrosion-inhibition drag reducer for alkyl porphyrin compound natural gas pipelines and preparation method of corrosion-inhibition drag reducer

A technology of porphyrin compounds and alkyl porphyrins, applied in pipeline systems, organic chemistry, mechanical equipment, etc., can solve the problems of complicated operation, increase the potential accident rate, reduce the actual application effect, etc., and achieve good drag reduction and anti-corrosion performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

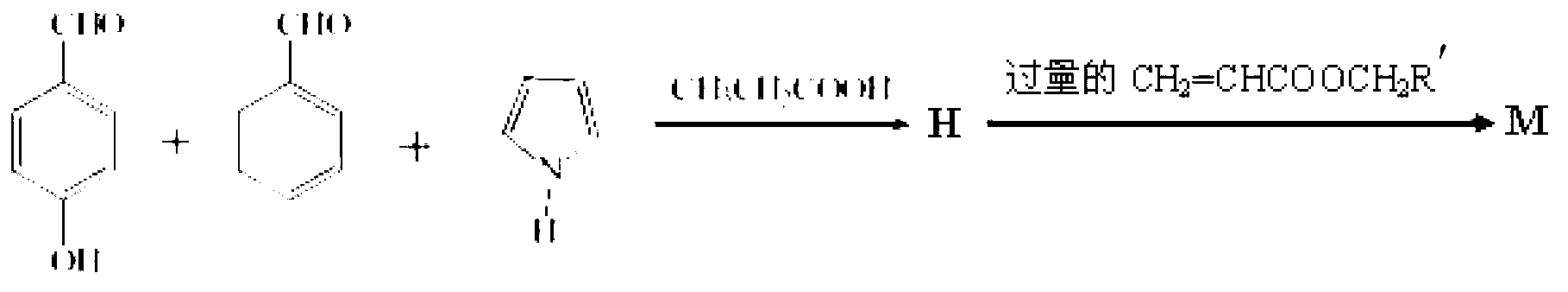

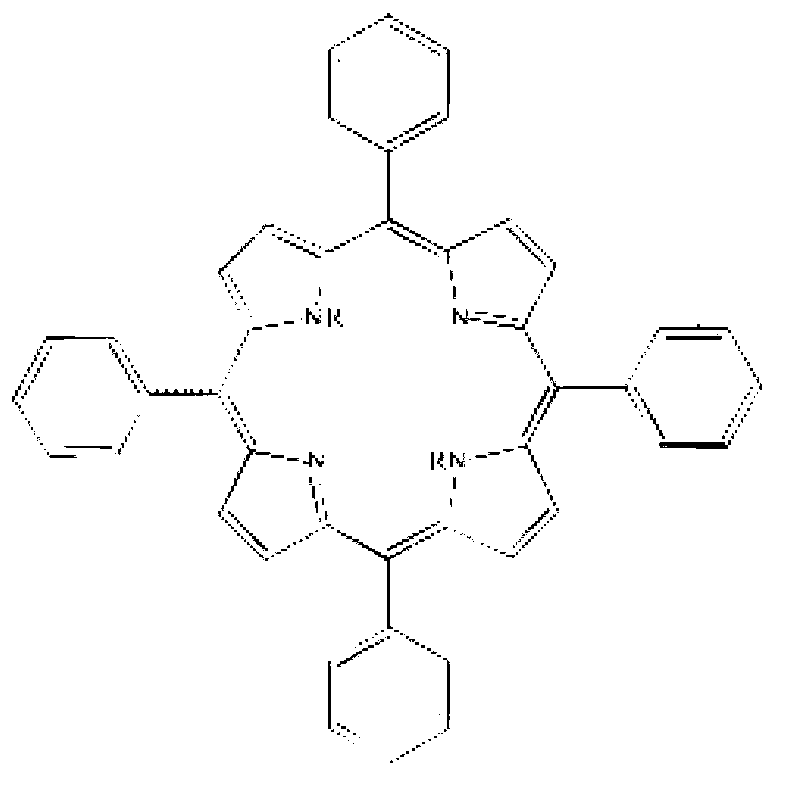

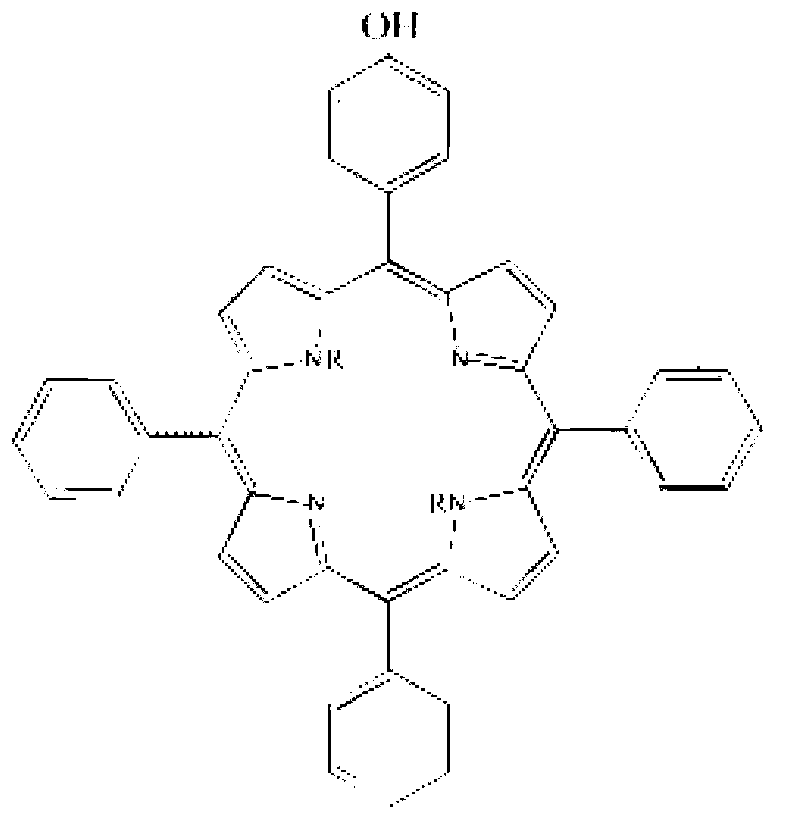

[0025] Add 200ml propionic acid into a 1000ml three-necked flask, heat to a slight boiling state and add benzaldehyde and 4-hydroxybenzaldehyde, the molar ratio of benzaldehyde and 4-hydroxybenzaldehyde is 1:1, the volume of benzaldehyde and propionic acid Ratio is 1:40, form benzaldehyde and 4-hydroxybenzaldehyde mixed solution after stirring rapidly and fully dissolving; Pyrrole is dissolved in propionic acid, is made into the solution of 10vol l.%, under stirring condition, the propionic acid solution of pyrrole Slowly drop into the mixed solution of benzaldehyde and 4-hydroxybenzaldehyde, the molar ratio of benzaldehyde to pyrrole is 1:2. Heat the mixture to 125°C, reflux and stir to react for 1 hour, then cool to 65°C under stirring, add absolute ethanol, the volume ratio of benzaldehyde to ethanol is 1:20, stir and cool to room temperature, and let it stand in an ice bath. Set aside for 12 hours; suction filter the reaction mixture 5 times, and wash the filter cake with ...

Embodiment 2

[0028] Add 200ml propionic acid into a 1000ml three-necked flask, heat to a slight boiling state and add benzaldehyde and 4-hydroxybenzaldehyde, the molar ratio of benzaldehyde and 4-hydroxybenzaldehyde is 1:1, the volume of benzaldehyde and propionic acid Ratio is 1:40, form benzaldehyde and 4-hydroxybenzaldehyde mixed solution after stirring rapidly and fully dissolving; Pyrrole is dissolved in propionic acid, is made into the solution of 10vol l.%, under stirring condition, the propionic acid solution of pyrrole Slowly drop into the mixed solution of benzaldehyde and 4-hydroxybenzaldehyde, the molar ratio of benzaldehyde to pyrrole is 1:2. Heat the mixture to 125°C, reflux and stir to react for 1 hour, then cool to 65°C under stirring, add absolute ethanol, the volume ratio of benzaldehyde to ethanol is 1:20, stir and cool to room temperature, and let it stand in an ice bath. Set aside for 12 hours; suction filter the reaction mixture 5 times, and wash the filter cake with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com