Method for combining amorphous alloy and heterogeneous material and complex

A technology of amorphous alloys and heterogeneous materials, applied in chemical instruments and methods, thin material processing, metal layered products, etc., can solve the problems of limiting amorphous alloy system, high cost, increasing production cost, etc., to reduce forming The requirements of capacity and performance, the requirements for reducing elastic deformation, and the effect of improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

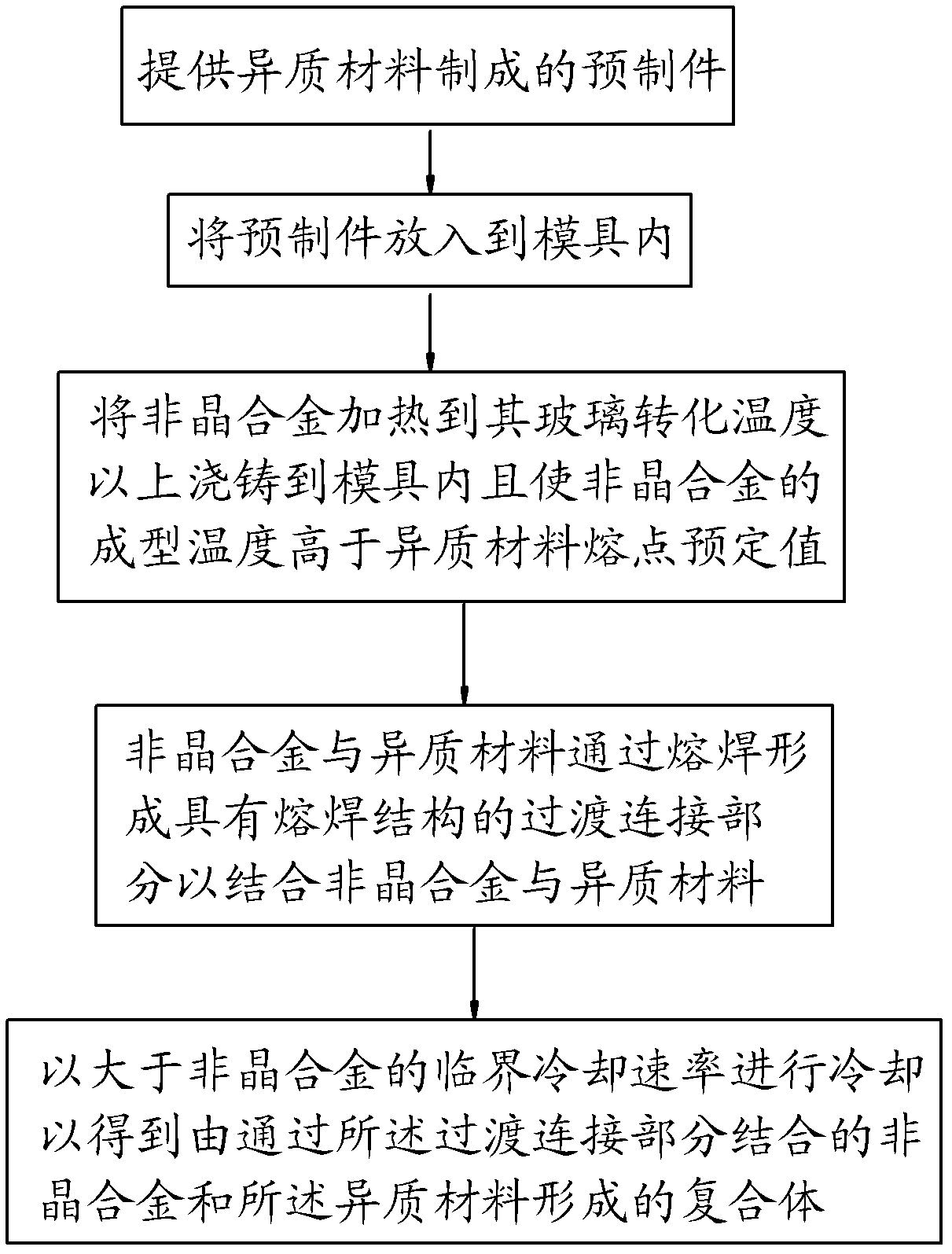

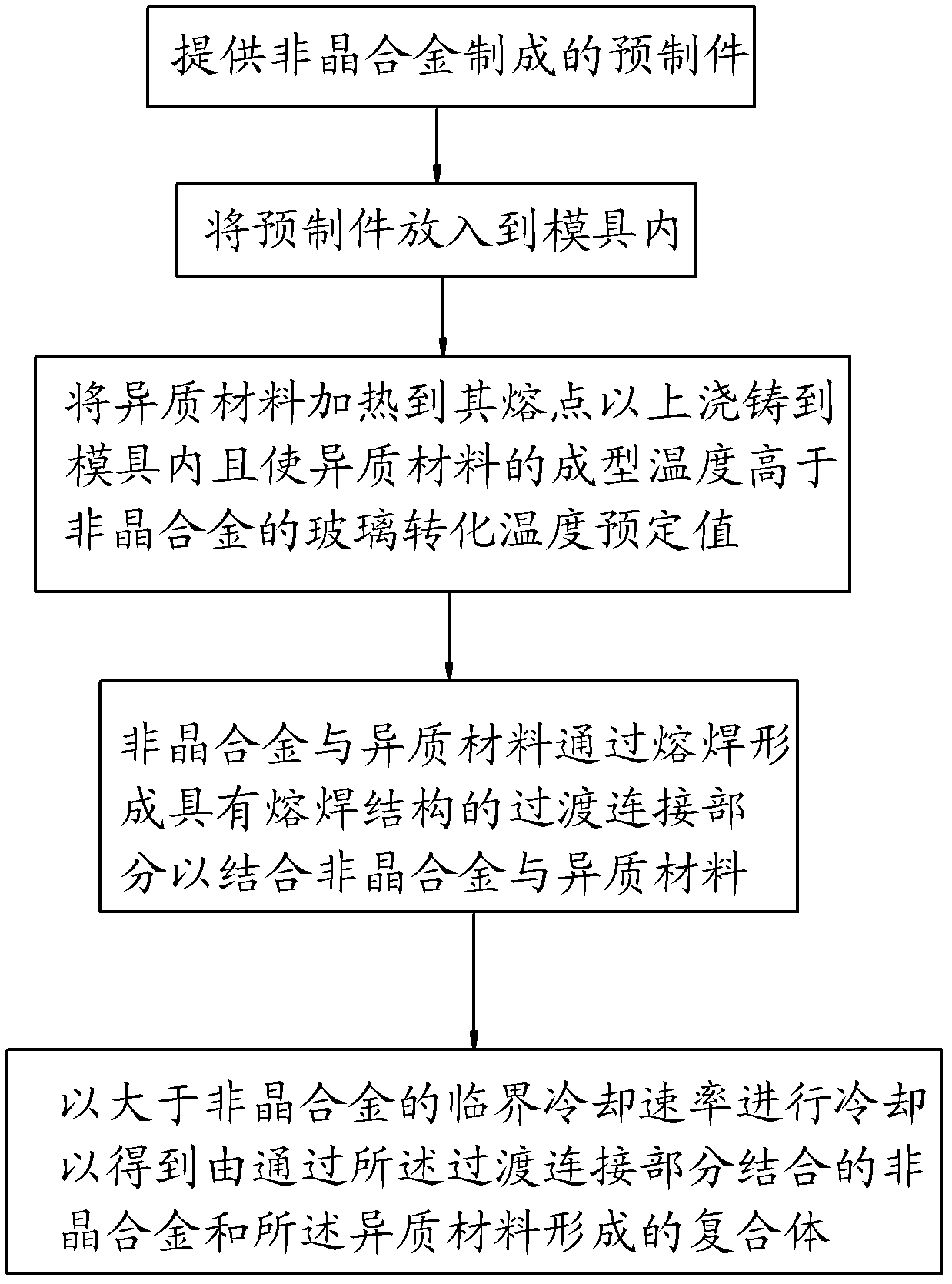

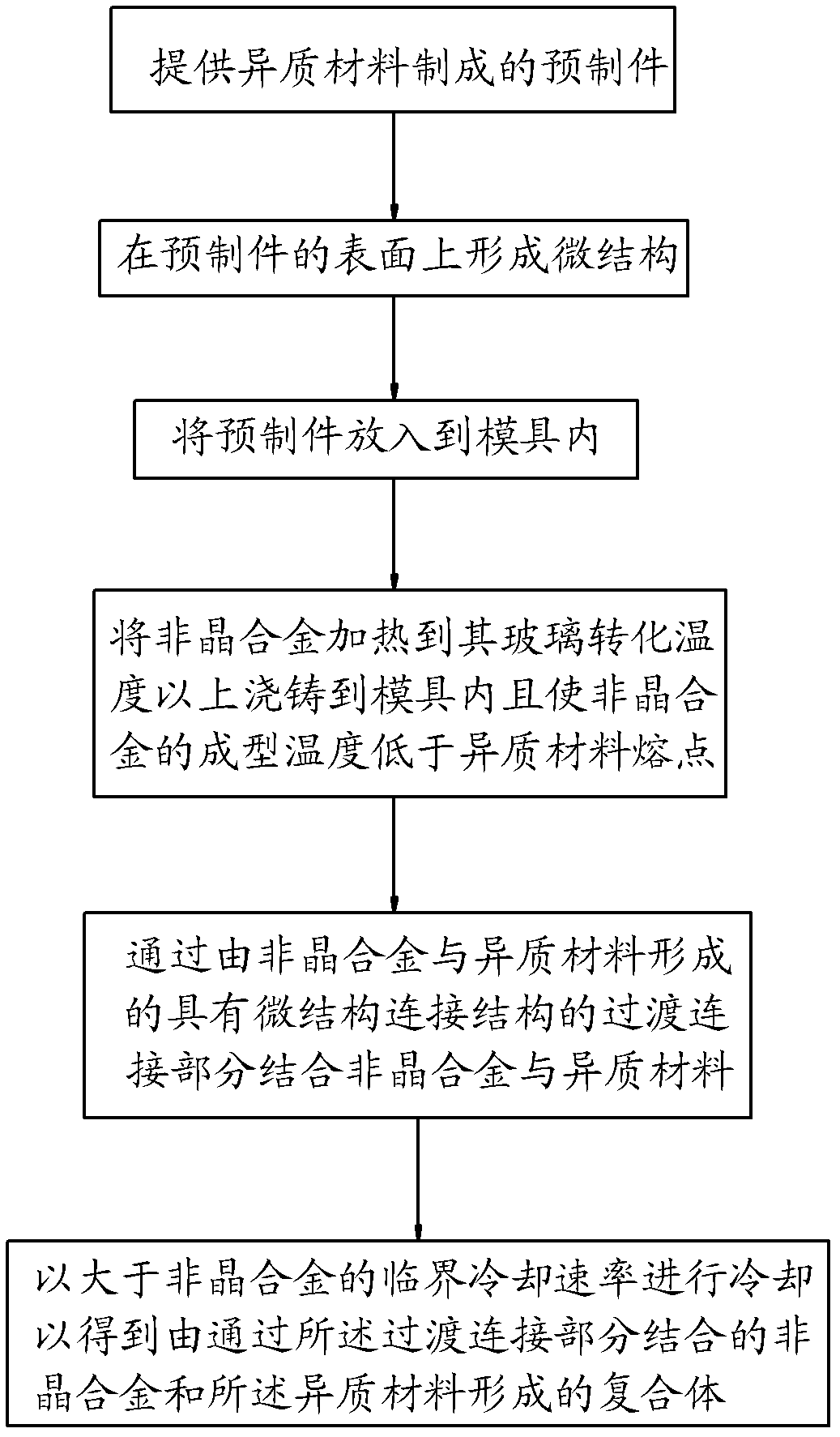

[0106] The glass transition temperature and melting point of the amorphous alloy obtained by the DSC curve test are 420 ° C and 835 ° C respectively, and are obtained by X Ray diffraction proves that the amorphous alloy is a complete amorphous structure; stainless steel, magnesium alloy, aluminum alloy, zinc alloy and amorphous alloy are respectively made Figure 12 Middle prefabricated part 12, its material is shown in Table 1, the prefabricated part cross-sectional size is 1.1mm×4.1mm, the length is 80mm, and the workpiece of 2mm×6mm×100mm is respectively prepared with stainless steel and amorphous alloy as a comparative example, in which stainless steel , magnesium alloy, and aluminum alloy are prepared by shot blasting to prepare the surface microstructure. After the preparation, the surface Ra is 100 μm, and then the stainless steel, magnesium alloy, aluminum alloy, and zinc alloy prefabricated parts are respectively placed in the die-casting mold and fixed. The amorphous...

example 2

[0111] The glass transition temperature and melting point of the amorphous alloy obtained by the DSC curve test are 420 ° C and 835 ° C respectively, and the X-ray Diffraction proves that the amorphous alloy is a complete amorphous structure; stainless steel, magnesium alloy, aluminum alloy, zinc alloy and amorphous are respectively made Figure 12 In the prefabricated part 12, the material of the heterogeneous material is shown in Table 2. The cross-sectional size of the prefabricated part is 1.1 mm × 4.1 mm, and the length is 80 mm. At the same time, a workpiece of 2 mm × 6 mm × 100 mm is prepared from an amorphous alloy as a comparative example. Among them, stainless steel, Magnesium alloys, aluminum alloys, and amorphous alloys are shot peened with steel shots of different particle sizes to obtain surface microstructures. The obtained surface microstructures are shown in Table 2, and then stainless steel, magnesium alloys, aluminum alloys, and zinc alloys are prefabricated ...

example 3

[0119] Table 3 below lists the performance comparison data of amorphous alloys and heterogeneous metal materials connected by fusion welding and non-fusion welding, in which the composition, melting point, glass transition temperature, melt forming temperature, and surface of the preform of the amorphous alloy The state, the melting point of the heterogeneous metal material, the molding temperature and the resulting connection method are listed in Table 3, and the connection performance data of the composite formed by the connection of the two heterogeneous materials are also listed in Table 3. The preparation method of composite molding of amorphous alloy and heterogeneous metal material is the same as Example 1.

[0120] It can be seen from Table 3 that the bonding strength and impact toughness of the amorphous alloy and the heterogeneous material according to the embodiment of the present invention are significantly higher than those of the comparative example, where part of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical dimension | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com