Plasma processing apparatus and method for adjusting process rate of marginal area of substrate

A processing device and plasma technology, applied to discharge tubes, electrical components, circuits, etc., can solve the problems of reduced yield, poor uniformity, and huge loss of edge effects of semiconductor process parts, so as to compensate for edge effects and avoid arcing The effect of discharge and ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

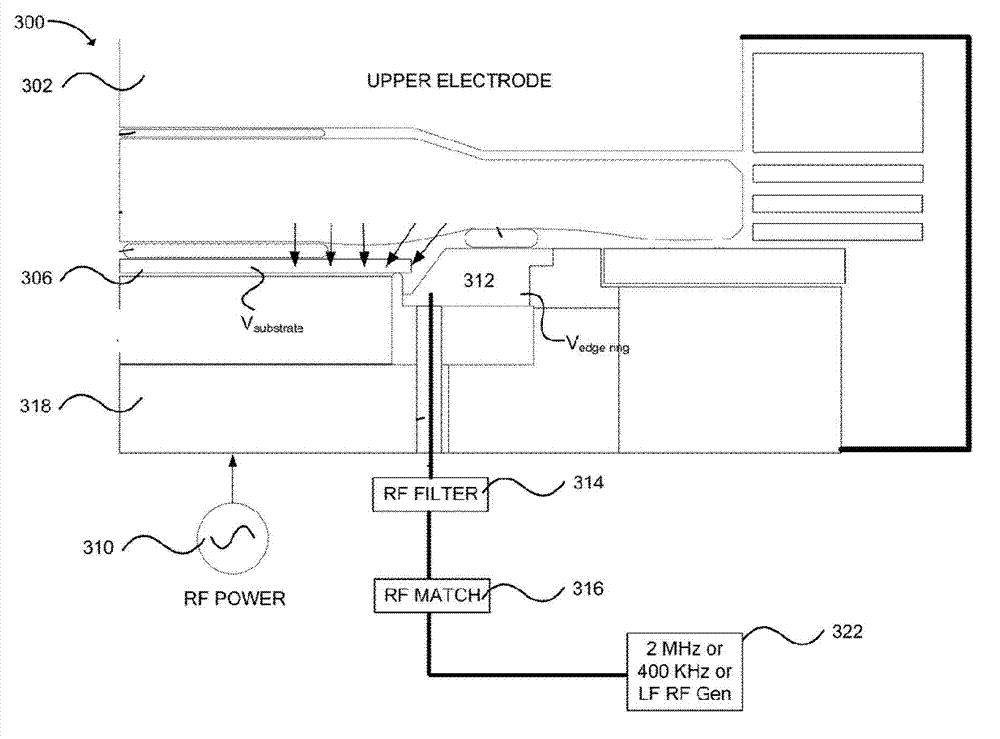

[0060] figure 1 It is a structural schematic diagram of a plasma processing device in the prior art, such as figure 1 As shown, the plasma processing apparatus 300 includes a parallel upper electrode 302 and a lower electrode 318, the lower electrode 318 is connected with a radio frequency power supply, and the substrate 306 is placed on the platform. A focus ring 312 is also provided on the periphery of the substrate 306 . The focus ring 312 is also connected to a low-frequency radio frequency power supply 322 , and a matching network 316 and a radio frequency filter 314 are connected in series between the low-frequency radio frequency power supply 322 and the focus ring 312 . In the prior art, the low-frequency radio frequency energy is coupled to the focus ring 312 near the periphery of the substrate 306 through the low-frequency filter 314 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com