Power-on water-bath steel wire quenching heat treatment method

A heat treatment method, electric water bath technology, applied in the field of heat treatment, can solve the problems of poor insulation between equipment and pipelines, high cost of steel wire heat treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

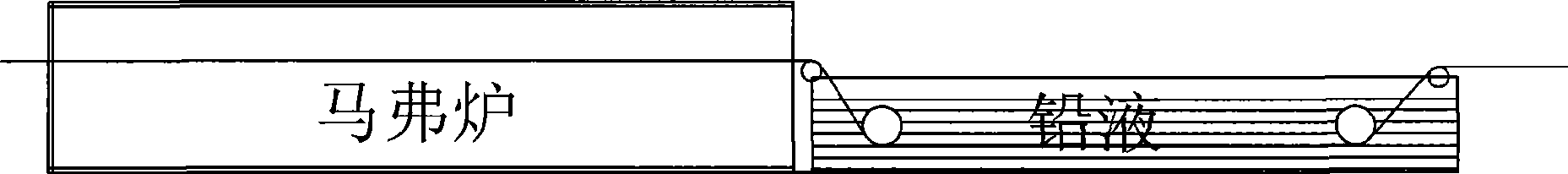

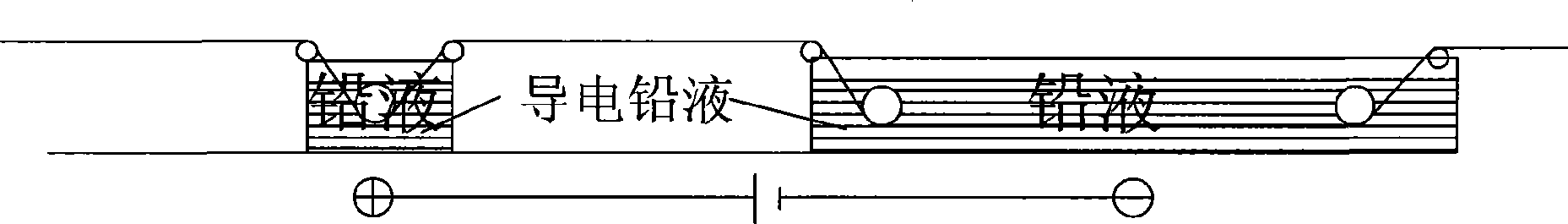

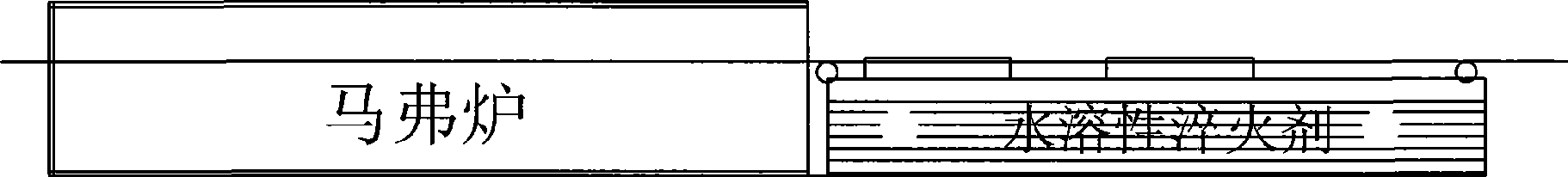

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Depend on Figure 4 As shown, the steel wire 1 of the present invention is tensioned by the tension adjuster 4, passes through the insulating protection sleeve 5 after tensioning, and then is pressed by the insulating tension roller 6, then passes through the first conductive roller 7, and passes through the refractory insulation cover 8 horizontally, After passing through the parallel insulated idler roller 9 on the same plane as the first conductive roller 7, and then compressed by the second conductive roller 11 and sprayed by the cold water pipe 10, it enters the two upper parts connected to the water bath above the water bath 13. In the groove 12, the steel wire passes through the two upper grooves 12 quickly at a speed of more than 30m per minute, and is rapidly cooled to realize the quenching of the steel wire 1, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com