Device for improving obdurability of medium-thickness plate steel in rolled steel

A technology of strong toughness and plate steel, which is applied in the field of devices for improving the strength and toughness of rolled medium and thick plate steel, can solve the problems of uneven heating on both sides of the medium and heavy plate, high labor intensity of staff, and high risk, so as to reduce labor intensity, Improve safety and facilitate limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

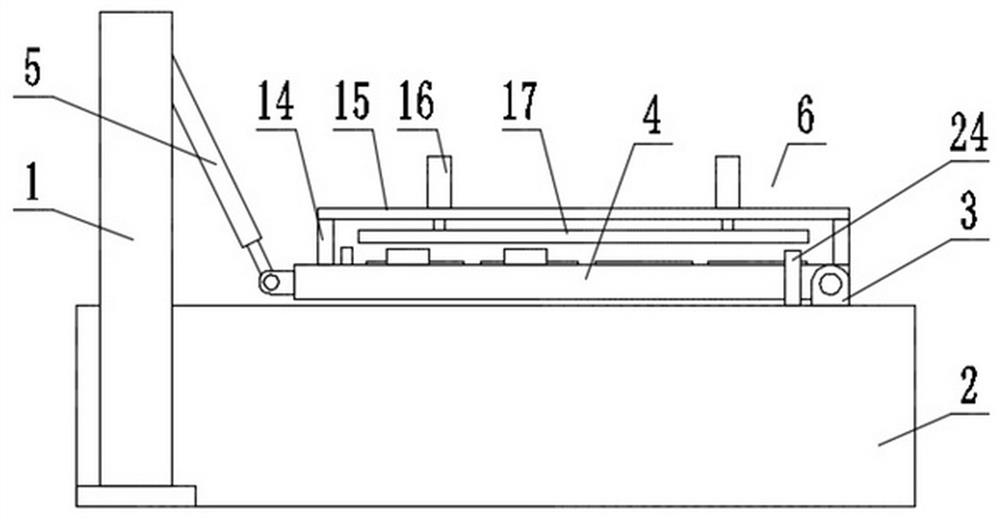

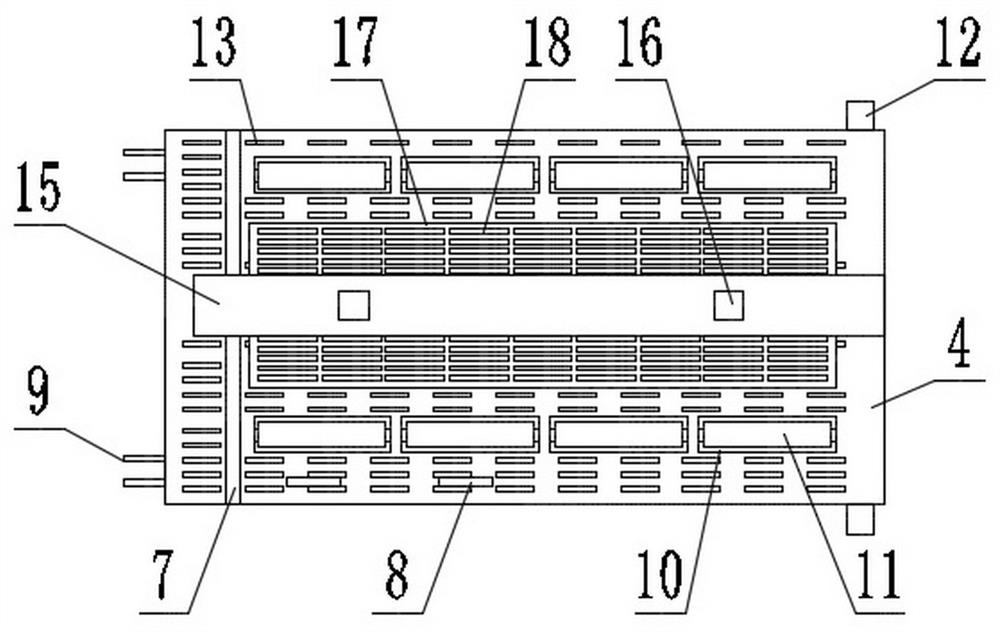

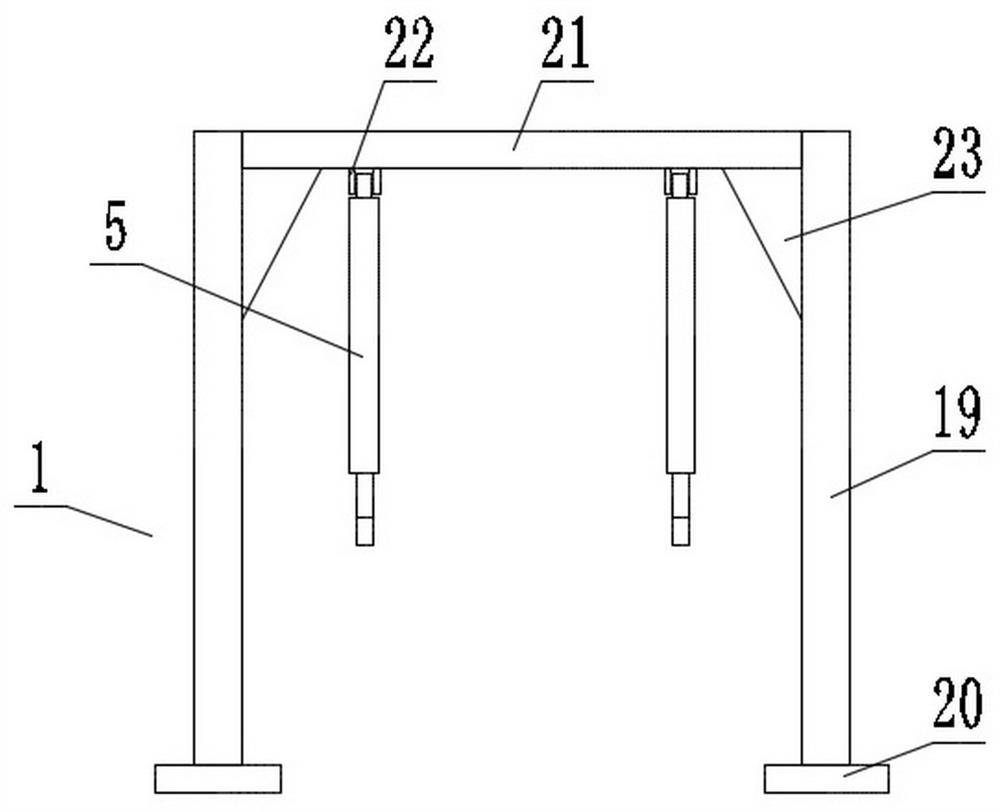

[0024] see Figures 1 to 3 , In the embodiment of the present invention, a device for improving the strength and toughness of rolled medium and thick plate steel includes a support mechanism 1, a quenching pool 2 and a transverse plate 4, the width of the transverse plate 4 is smaller than the width of the inner wall of the quenching pool 2, and the supporting mechanism 1 is arranged across one end of the quenching pool 2, and two first hydraulic cylinders 5 are symmetrically connected in the support mechanism 1 in rotation. 2. Rotationally connected, the other end of the horizontal plate 4 is connected in rotation with the movable end of the first hydraulic cylinder 5, and the two sides of the horizontal plate 4 away from the first hydraulic cylinder 5 are symmetrically fixedly connected with a connecting shaft 12, and the connecting shaft 12 is rotatably connected with a connection Plate 3, the bottom of the connecting plate 3 is fixedly connected to the top of the side wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com