A circulating crude oil storage tank oil gas vacuum adsorption recovery system

A crude oil storage tank and vacuum adsorption technology, which is applied to containers, large containers, packaging, etc., can solve the problems of lack of convenience and conciseness, and achieve the effects of easy remote monitoring, fast desorption speed, and elimination of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

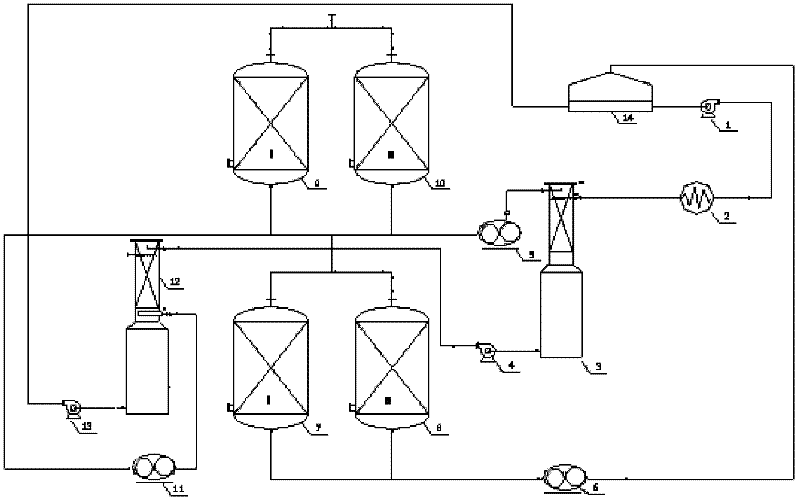

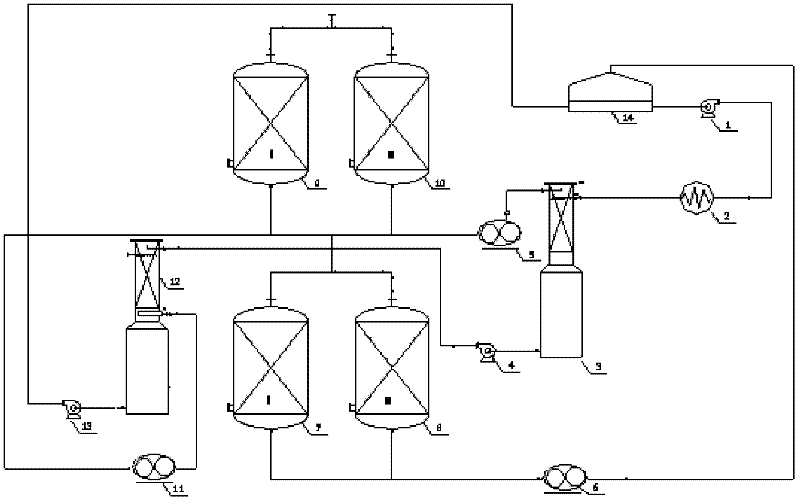

[0033] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0034] The circulation type crude oil storage tank oil gas vacuum adsorption recovery system of the present invention comprises: crude oil storage tank 14, vacuum desulfurization device 5, 7, 8, adsorption tank 9, 10, vacuum pump C 11, absorbent treatment device 2, 3, 6 and The absorption tower 12, the vacuum desulfurization device includes a vacuum pump A and a desulfurization tank, the absorbent treatment device includes a heater 2, a cooling tower 3 and a vacuum pump B6, and the crude oil stored in the crude oil storage tank 14 passes through the The oil supply pipeline flows through the heater 2, and after being moderately heated by the heater 2, the viscosity of the crude oil is reduced, and enters the cooling tower 3, where the gas and liquid are separated after being condensed in the cooling tower 3, and the gaseous light hydrocarb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com