Power plug

A technology of power plugs and sockets, which is applied in the direction of circuits, electrical components, coupling devices, etc., can solve problems such as sparking phenomenon, large pull-out force, force instability, etc. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

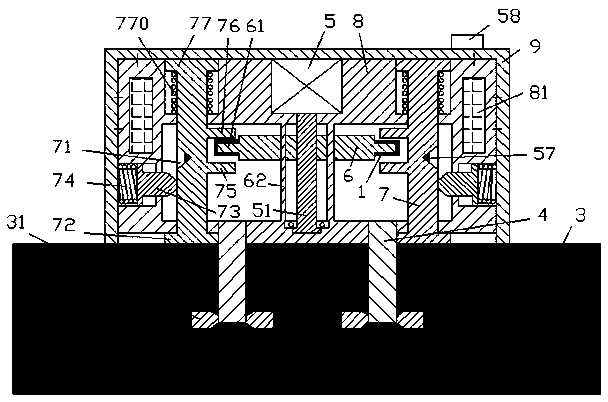

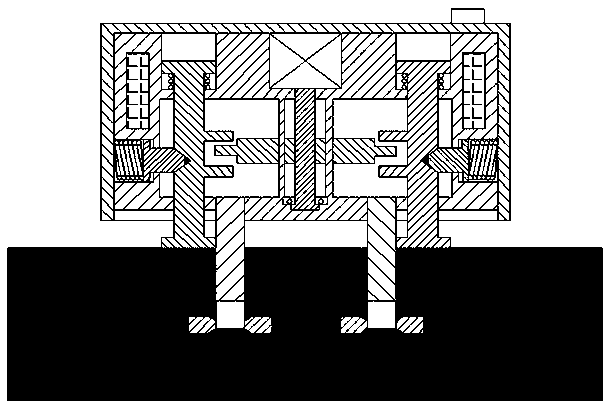

[0010] Combine below Figure 1-2 The present invention will be described in detail.

[0011] A power plug according to an embodiment includes a frame body 8 fixedly provided with an outer casing 9 and two plug pins 4 fixedly connected to the frame body 8 and symmetrically arranged left and right, and the two plug pins 4 are used to be inserted into In the hole of the socket 3 to be in electrical contact with the contacts 31 respectively, the frame body 8 can also be slidably fitted with two push-off pillars 7 arranged symmetrically on the left and right, and the structure of the two push-off pillars 7 is a mirror image Symmetrical and each of the push-off columns 7 includes a push-off column foot 72 at the lower end for engaging with the socket 3, a wedge-shaped groove on the outwardly facing side of the push-off column 7 71. The upper stressed convex plate 76 and the lower stressed convex plate 75 located on the inwardly facing side of the push-off column 7, and the limit po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com