Plug assembly for electric power

A technology of plug components and electric power, which is applied in the direction of electrical components, parts of connecting devices, circuits, etc., can solve problems such as sparking phenomenon, large pull-out force, force instability, etc., to solve the problem of difficult pull-out and safe operation Reliable, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

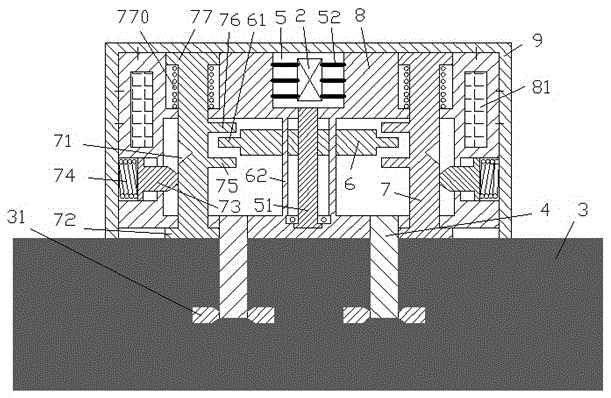

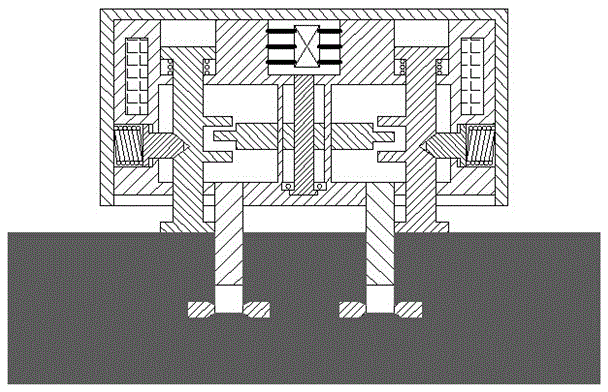

[0010] Combine below Figure 1-2 The present invention will be described in detail.

[0011] According to an embodiment, a plug assembly for electric power includes a frame body 8 fixedly provided with an outer casing 9 and two plug pins 4 fixedly connected to the frame body 8 and symmetrically arranged left and right, the two plug pins 4 Used to be inserted into the holes of the socket 3 to make electrical contact with the contacts 31 respectively, the frame body 8 can also be slidably fitted with two push-off columns 7 symmetrically arranged left and right, and the two push-off column pieces The structure of 7 is mirror-symmetrical and each of the push-off column parts 7 includes a push-off column pin 72 at the lower end for engaging with the socket 3, and is located on the outward-facing side of the push-off column part 7. The wedge-shaped groove 71, the upper stressed convex plate 76 and the lower stressed convex plate 75 located on the inwardly facing side of the push-of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com