Apparatus and methods for joining composite structures of aircrafts

A technology of equipment and composite wings, applied in the field of aircraft, can solve problems such as increasing the cost of aircraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

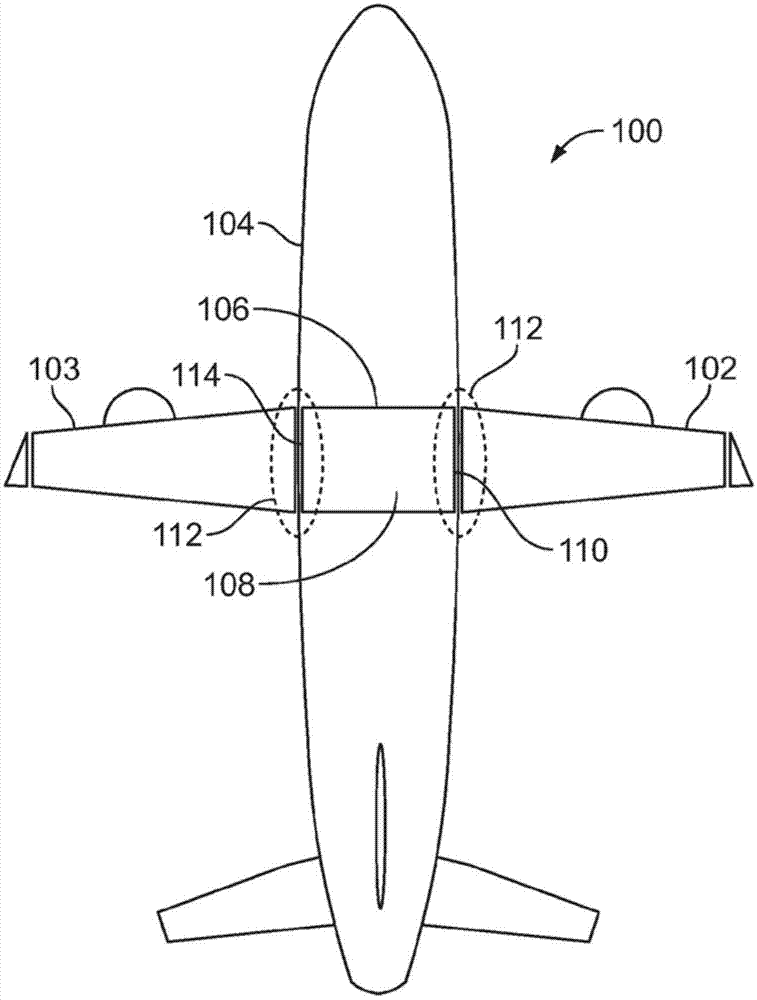

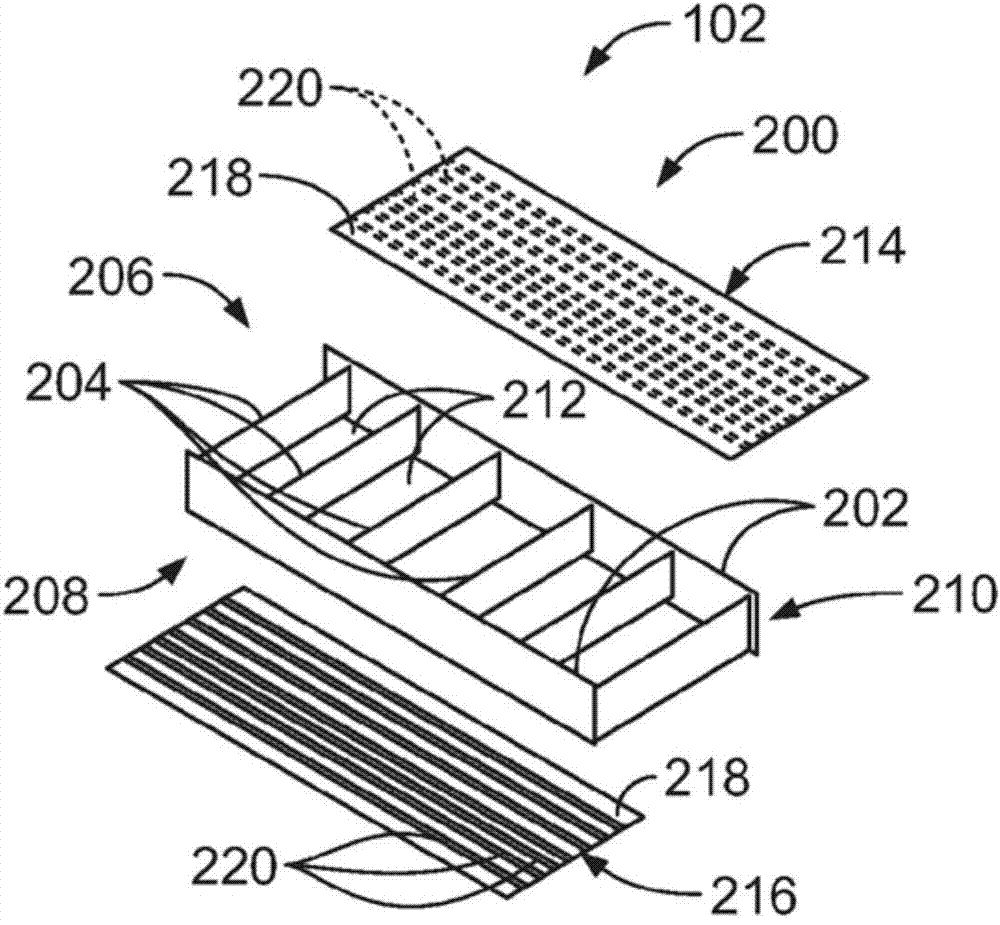

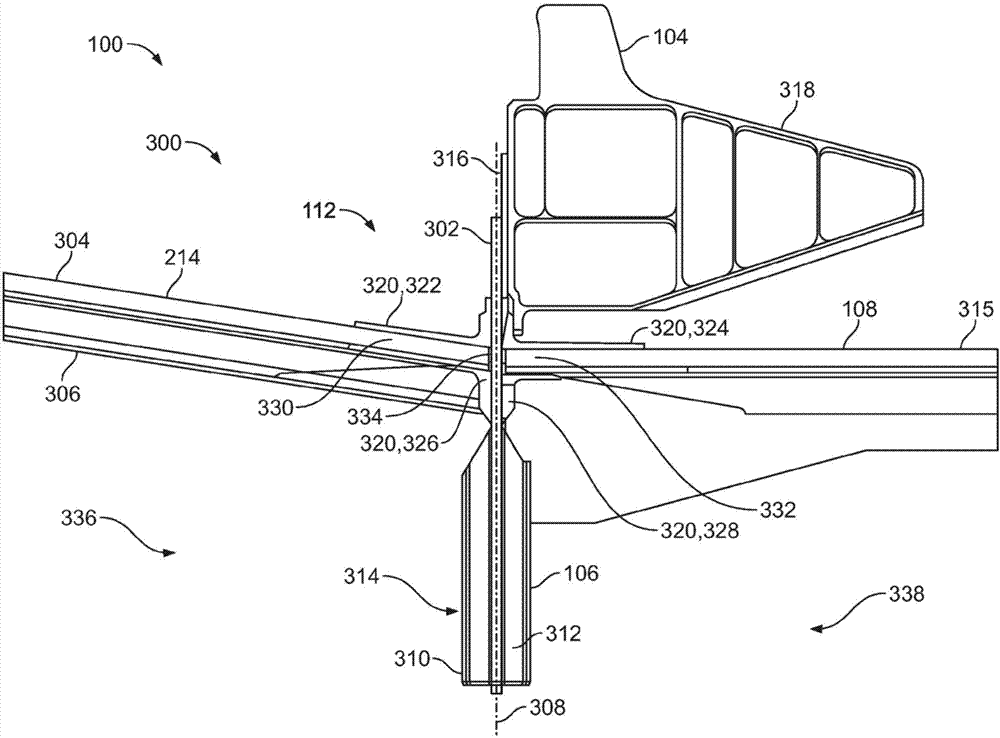

[0022] Aircraft wings are typically coupled to the central wing box of the fuselage via an upper wing joint assembly. For example, a double sine rod is an exemplary upper wing joint assembly commonly used in larger aircraft, such as jumbo jets, to couple the upper wing to the central wing box. The double sine bar has a cruciform profile comprising vertically extending flanges coupled to the sides of the fuselage skin and body ribs or the web of the central wing box. The double sine bar also includes flanges extending laterally or horizontally to each side of the vertically extending flanges that connect or engage (eg, mechanically couple) the upper surfaces of the outboard fins of the wing and the inboard fins of the central wing box . Specifically, the outboard and inboard tabs are directly coupled to the laterally extending flanges of the double sine bar via fasteners. Double sine rod type joints constructed of aluminum are commonly used for fins constructed of metallic ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com