Method for aeroelastic tailoring of composite wing and genetic/sensitivity-based hybrid optimization method of composite wing

An aeroelastic, composite material technology, applied in the field of genetic/sensitivity hybrid optimization, can solve problems such as increased bending and torsional deformation, reduced aileron efficiency, and significant aeroelastic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

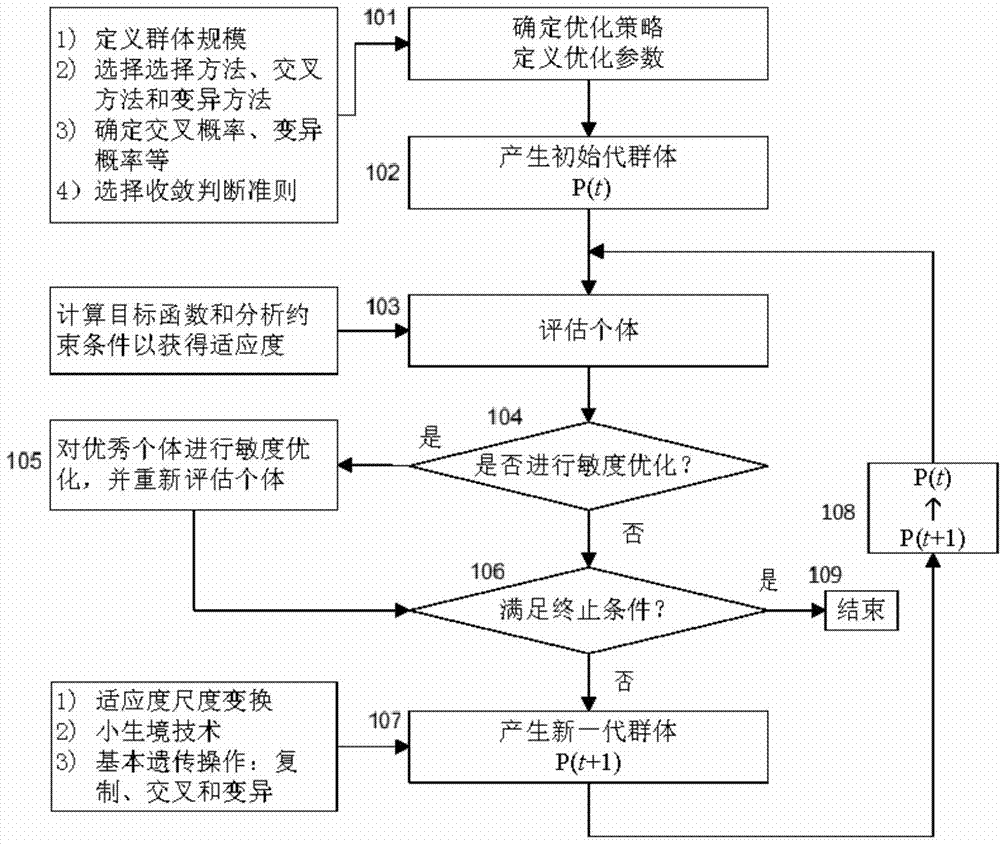

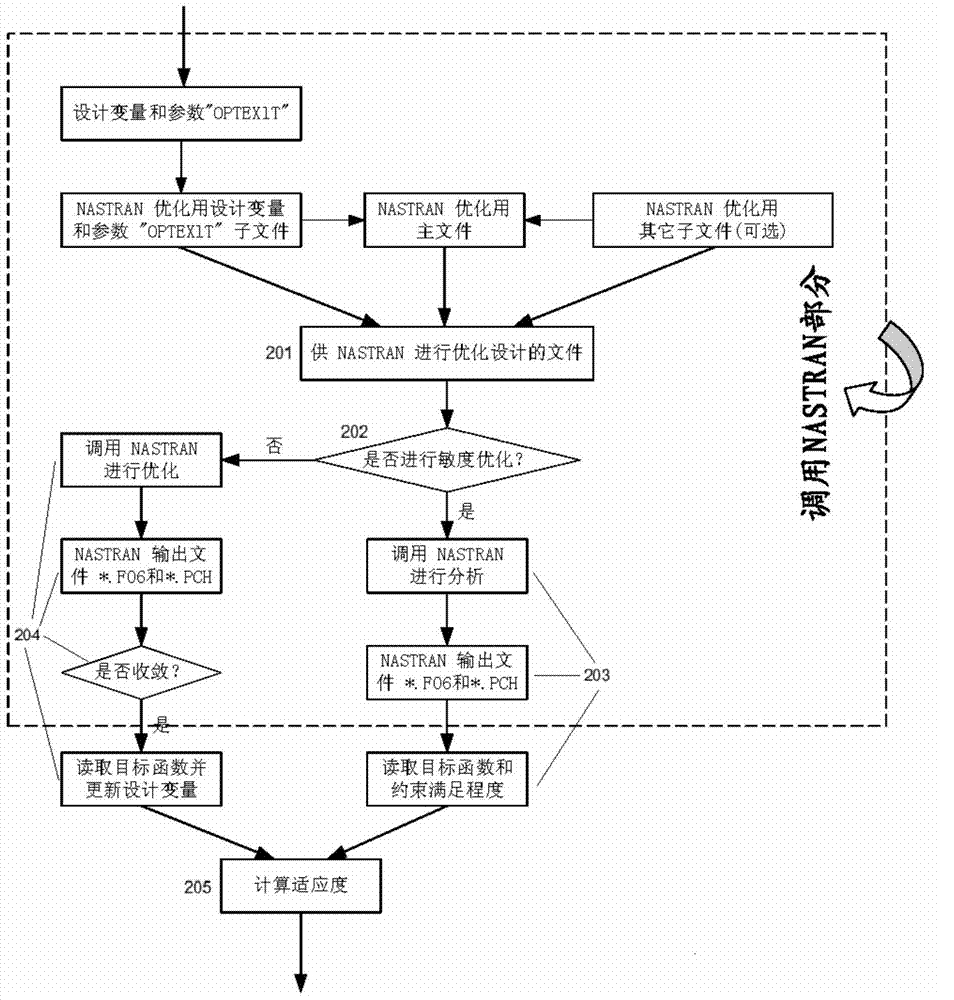

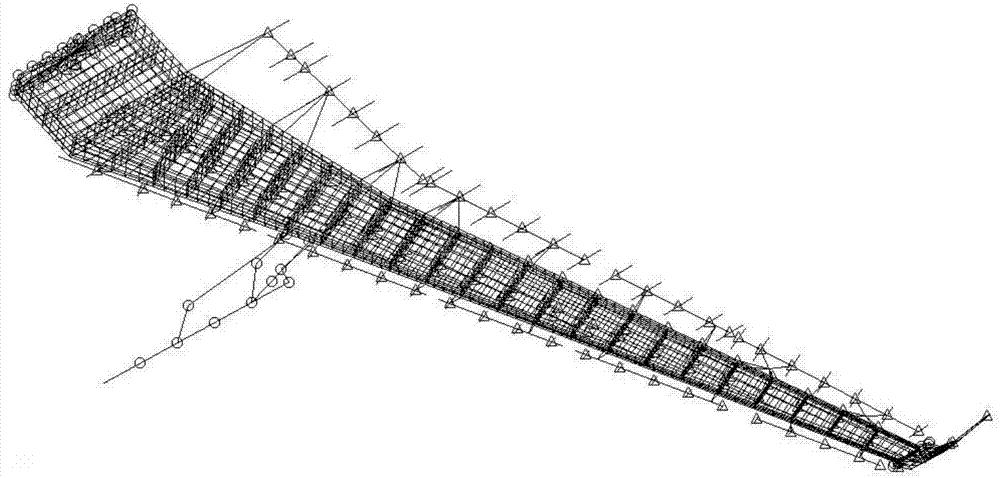

[0012] A key to the aeroelastic tailoring of composite wings is to choose a reasonable and effective aeroelastic optimization method.

[0013] According to one aspect of the present invention, a genetic / sensitivity hybrid optimization method is provided, and an aeroelastic tailoring method of a composite material wing based on the optimization method is provided.

[0014] In the aeroelastic tailoring method of a composite wing according to an embodiment of the present invention, the aeroelastic tailoring of the wing is achieved through aeroelastic optimization, and aeroelastic optimization is one of the optimization problems, which is through genetic / Sensitivity hybrid optimization method to solve. In the present invention, the optimization problem can be expressed as searching for a set of design variables that minimizes the objective function F(v) in the ndv-dimensional space, namely:

[0015] Min. F(v) (1)

[0016] S.T. g j (v)≤0 j=1,2,...,n c (2)

[0017] v il ≤v i ≤v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com