Multi-connecting-rod sealed valve with front blade

A closed valve and multi-link technology, which is applied in the direction of valve lifts, valve devices, engine components, etc., can solve the problems of increased rotational torque of valves, difficulty in ensuring sealing, difficulty in opening and closing, etc., to reduce movement Effect of torsion, reasonable structure, and load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

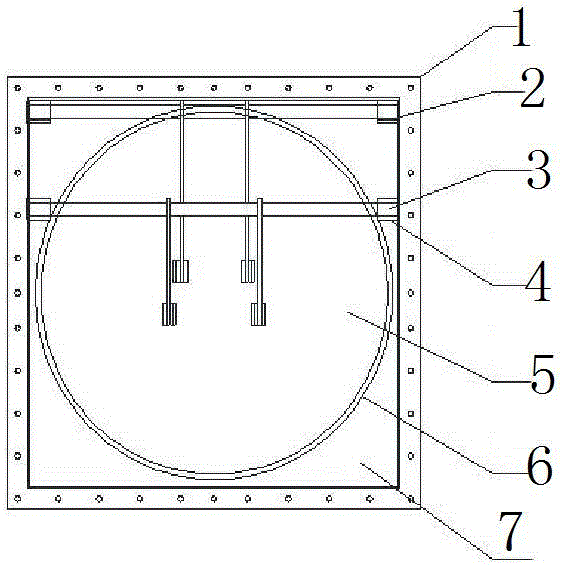

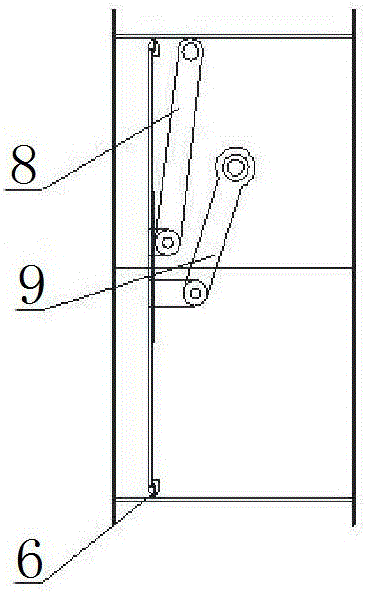

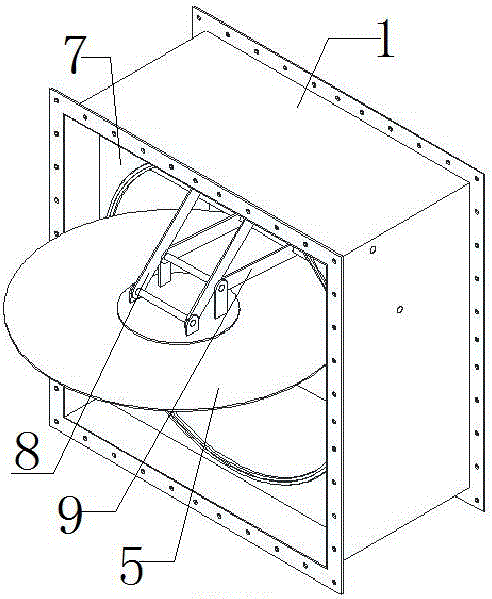

[0012] Such as Figure 1-3 As shown, a vane front multi-link hermetic valve includes a valve body 1, vanes 5, a square circle 7, a support cantilever 8, and a power arm 9. The top of the valve body 1 is provided with a driven shaft 2, and the driven shaft 2 is provided with a drive shaft 3 below, a support cantilever 8 is connected to the driven shaft 2, the other end of the support cantilever 8 is connected to the blade 5, a power arm 9 is connected to the drive shaft 3, and the other end of the power arm 9 is connected to the blade 5. The ends of the moving shaft 2 and the driving shaft 3 are provided with shaft sleeves 4 , the blades 5 are embedded in the square circle 7 , and a sealing strip 6 is arranged between the blades 5 and the square circle 7 .

[0013] The invention has a reasonable structure, can realize sealing through the pressure of the air flow itself, and basically does not generate friction, and the setting of the driven shaft and the supporting cantilever c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com