Combined muscular multi-directional bending flexible joint

A flexible joint, multi-directional technology, applied in the direction of artificial arms, manipulators, artificial legs, etc., can solve the problems of no multi-directional bending, high manufacturing cost, large volume, etc., and achieve low energy consumption, good coordination, and dynamic control high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below the present invention will further describe the implementation of various modes in conjunction with accompanying drawing:

[0036] (1) Artificial muscle components

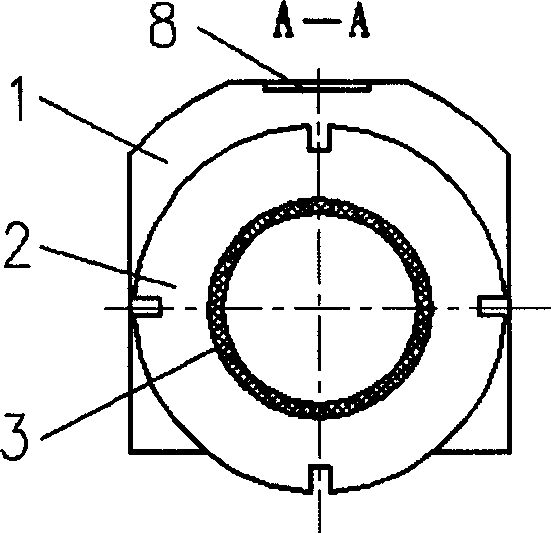

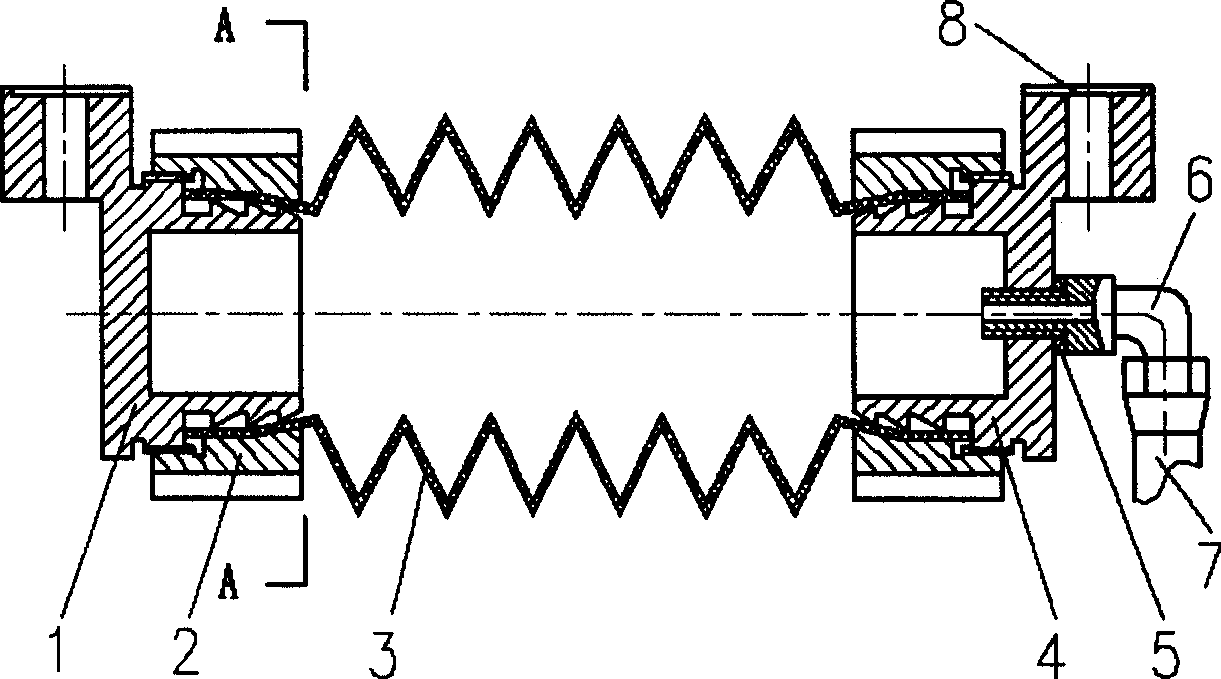

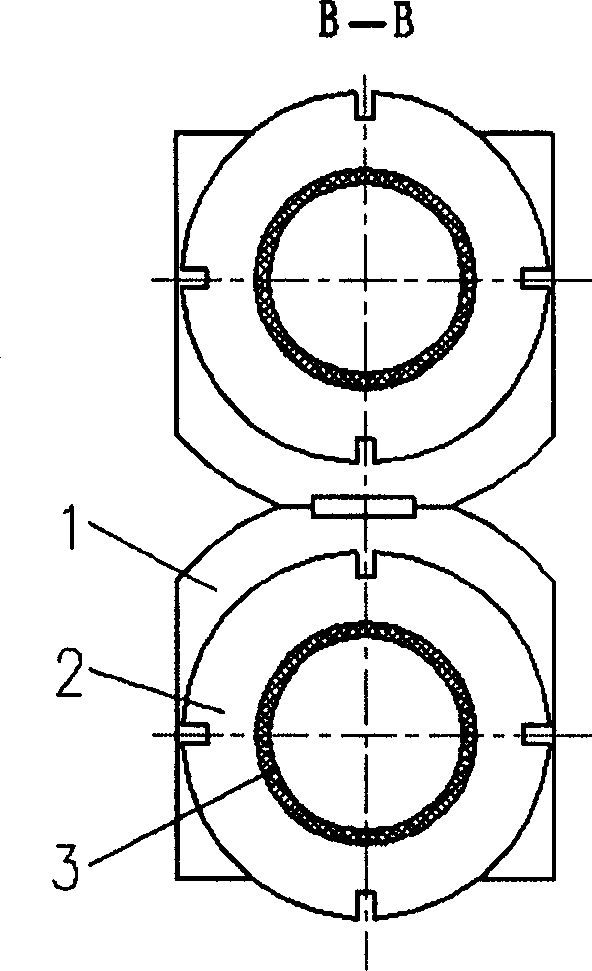

[0037] as attached Figure 1~2 As shown, the elastic bellows 3 is clamped on the bayonet of the headstock 1 and the tailstock 4 by the ferrule 2, and the elastic bellows 3, the headstock 1 and the tailstock 4 form a closed cavity; the fluid passes through the hose 7 and the The right-angle joint 6 enters the joint cavity, and there is a sealing ring 5 between the right-angle joint 6 and the tailstock 4; Guide grooves 8 with the same size; an independent fluid-driven artificial muscle assembly is formed by the above-mentioned parts.

[0038] The elastic bellows 3 is a rubber bellows, and the longitudinal section shape of the single-section elastic bellows can be in the shape of "V", "U", "Ω" and so on; wherein the elastic bellows 3 with a "V" cross-section are as attached Figures 17-18 As shown, al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com