Anti-stab fabric with shear thickening fluid and rheid

A fabric and fluid technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of restricting human body movements, rigid stab-proof fabrics, poor wearing comfort, etc., and achieve good wearing comfort, avoid leakage, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

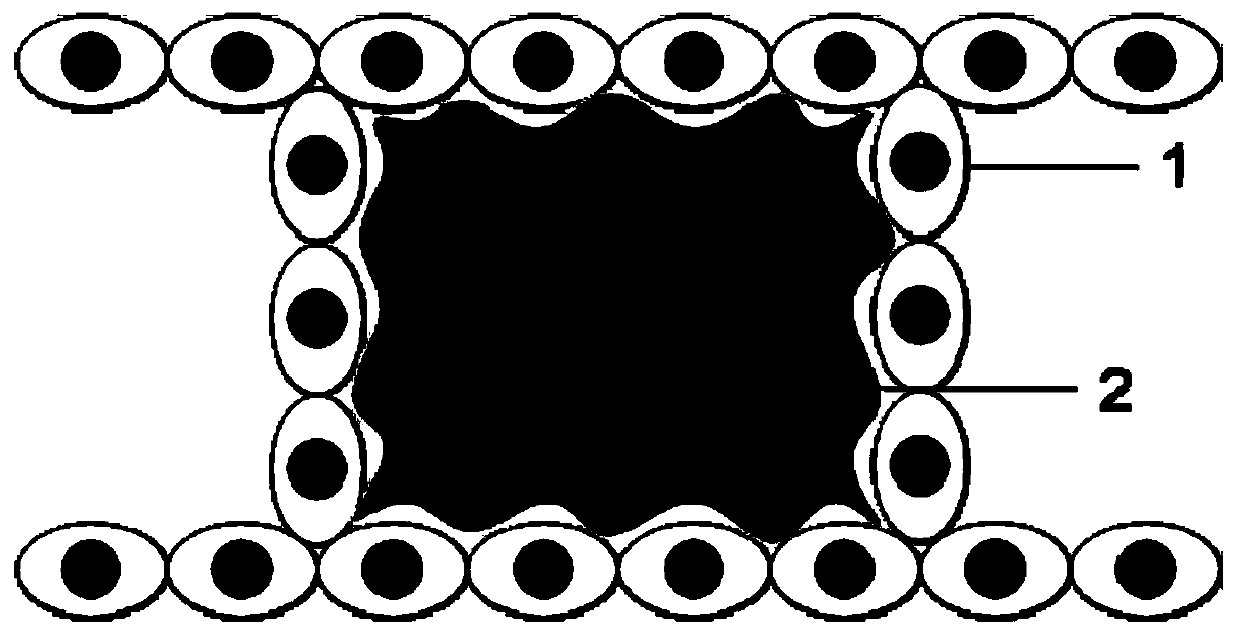

[0024] Such as figure 1 As shown, the present embodiment provides a kind of shear-thickening fluid soft stab-proof fabric, including an I-shaped three-dimensional structure fabric 1 as a skeleton material, and the I-shaped three-dimensional structure fabric 1 has a cavity, and the I-shaped three-dimensional structure fabric 1 has a cavity. A shear thickening fluid 2 is injected into the cavity of the three-dimensional structure fabric 1, and the shear thickening fluid 2 is used as the main body of the anti-stab material.

[0025] The I-shaped structure fabric is a woven fabric, and the inner surface of the cavity of the I-shaped three-dimensional structure fabric is impregnated with mold silica gel curing agent, and the preparation method of the shear thickening fluid is: oxidizing The silicon particles were evenly dispersed in the mold silica gel solution by ultrasonic vibration (the mold silica gel used was the 825 type mold silica gel produced by Quanzhou Quality Product El...

Embodiment 2

[0029] Such as figure 2 As shown, the present embodiment provides a kind of shear-thickening fluid soft stab-proof fabric, including spacer fabric 3 as skeleton material, and described spacer fabric 3 has a cavity, and the shear thickening fluid is injected into the cavity of spacer fabric 3. Thick fluid 2, with shear thickening fluid as the main body of the anti-stab material.

[0030] The spacer fabric is a woven fabric, and the inner surface of the cavity of the spacer fabric is impregnated with mold silica gel curing agent. The preparation method of the shear thickening fluid is as follows: the silicon dioxide particles with a particle size of 30.8 μm are uniformly vibrated by ultrasonic vibration. Disperse in the mold silica gel solution (wherein the mold silica gel used is the 825 type mold silica gel produced by Quanzhou Quality Product Electronic Commerce Co., Ltd., and the silicon dioxide particles are produced by Shangqiu Liangfeng Sanitary Products Co., Ltd.), to o...

Embodiment 3

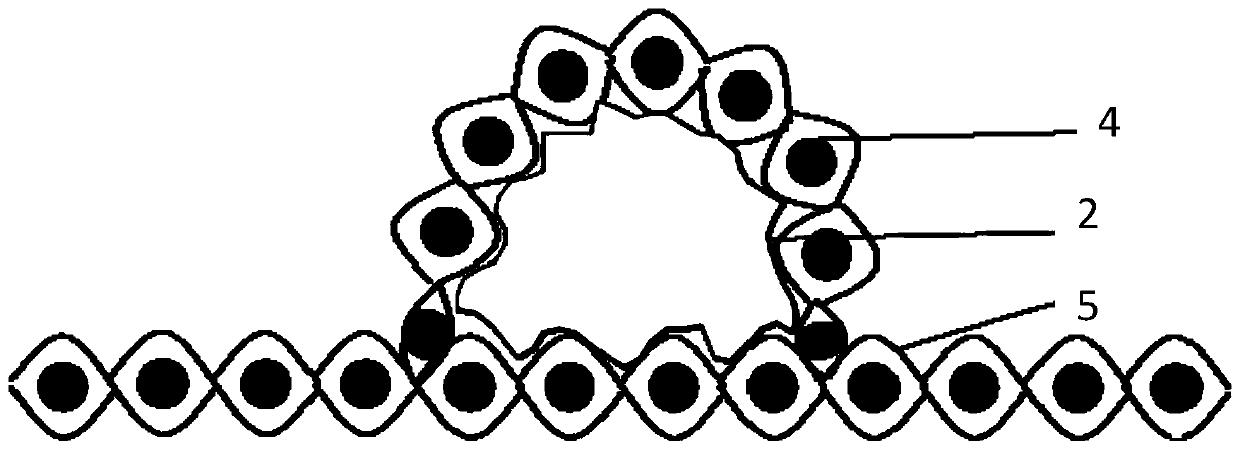

[0034] Such as image 3 As shown, the present embodiment provides a shear-thickening fluid soft stab-resistant fabric, including pleated fabric as a skeleton material, wherein the pleated part 4 and the non-pleated part 5 constitute a complete pleated fabric, and the The pleated part 4 has a cavity, and the shear thickening fluid 2 is injected into the cavity of the pleat part 4, and the shear thickening fluid is the main body of the anti-stab material.

[0035] The pleated fabric is a woven or knitted fabric, and the inner surface of the cavity of the pleated fabric is impregnated with a mold silica gel curing agent, and the preparation method of the shear thickening fluid is as follows: silica particles with a particle size of 30.8 μm Uniformly dispersed in the mold silica gel solution through ultrasonic vibration (wherein the mold silica gel used is the 825 mold silica gel produced by Quanzhou Quality Electronic Commerce Co., Ltd., and the silica particles are produced by S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com