Water-based organic-inorganic hybrid anti-freezing coating

An anti-icing, water-based technology, applied in the direction of anti-corrosion coatings, polyether coatings, epoxy resin coatings, etc., can solve the problem of long-lasting anti-icing without relevant research and investigation, no effective solution for moisture condensation or desublimation icing, Unable to meet the problems of anti-icing performance and other problems for a long time, to meet the long-term requirements, meet the needs of hydrophilicity and anti-icing performance, and the effect of good substrate adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

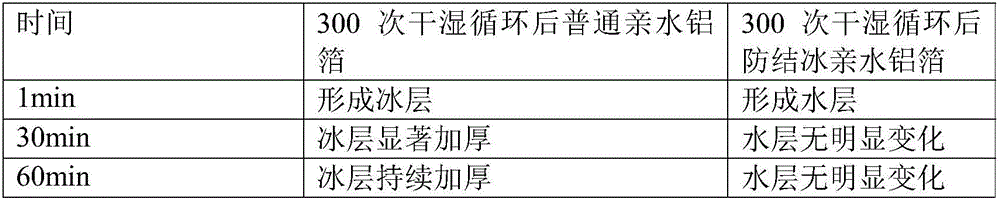

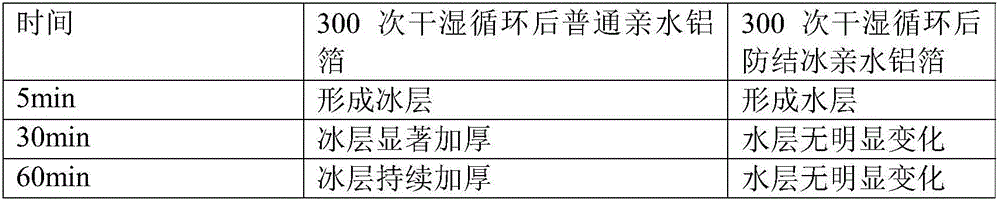

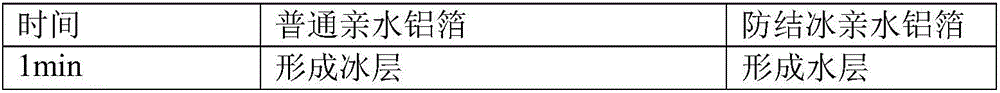

Image

Examples

Embodiment 1

[0046] 1. Preparation of hydrophilic acrylic starch modified superabsorbent resin:

[0047] Basic formula (parts by weight):

[0048] N, N dimethylbisacrylamide 5, acrylamide 50, starch 80, acrylic acid 50, ammonium persulfate 5, water 120, propylene glycol methyl ether 2, ethylene glycol butyl ether 20, water 100 (residual water).

[0049] According to the basic formula, mix N,N dimethylbisacrylamide, acrylamide, starch, acrylic acid, and water at a temperature of 80°C for 1 hour, add ammonium persulfate and the rest of water dropwise for 2 hours, and then keep warm for 10 hours to obtain a hydrophilic Acrylic starch modified superabsorbent resin.

[0050] 2. Preparation of anti-icing hydrophilic coating:

[0051] Basic formula (parts by weight):

[0052] Hydrophilic acrylic starch modified superabsorbent resin 80, sodium silicate 200, water-based acrylic polyurethane 30, polyethylene glycol 50, water 50, defoamer 2, dispersant 4, wetting agent 1.2, pH regulator 0.5, Rheo...

Embodiment 2

[0070] 1. Preparation of hydrophilic acrylic starch modified superabsorbent resin:

[0071] Basic formula (parts by weight):

[0072] N, N dimethylbisacrylamide 10, acrylamide 20, starch 100, acrylic acid 25, ammonium persulfate 10, water 80, propylene glycol methyl ether 10, ethylene glycol butyl ether 10, water 140 (residual water).

[0073] According to the basic formula, mix N,N dimethylbisacrylamide, acrylamide, starch, acrylic acid, and water at a temperature of 50°C for 1 hour, add ammonium persulfate and the rest of water dropwise for 2 hours, and then keep warm for 10 hours to obtain a hydrophilic Acrylic starch modified superabsorbent resin.

[0074] 2. Preparation of anti-icing hydrophilic coating:

[0075] Basic formula (parts by weight):

[0076] Hydrophilic acrylic starch modified superabsorbent resin 200, sodium silicate 100, water-based acrylic polyurethane 25, polyethylene glycol 60, water 90, defoamer 1, dispersant 8, wetting agent 0.5, pH regulator 7, Rh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com