Fluid-state cured recycled mixture, preparation method and application thereof in pit slot backfilling

A technology of recycled mixed materials and recycled fine aggregates, which is applied in the field of civil construction materials, and can solve problems such as poor environmental protection, difficult construction, and affecting backfill quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

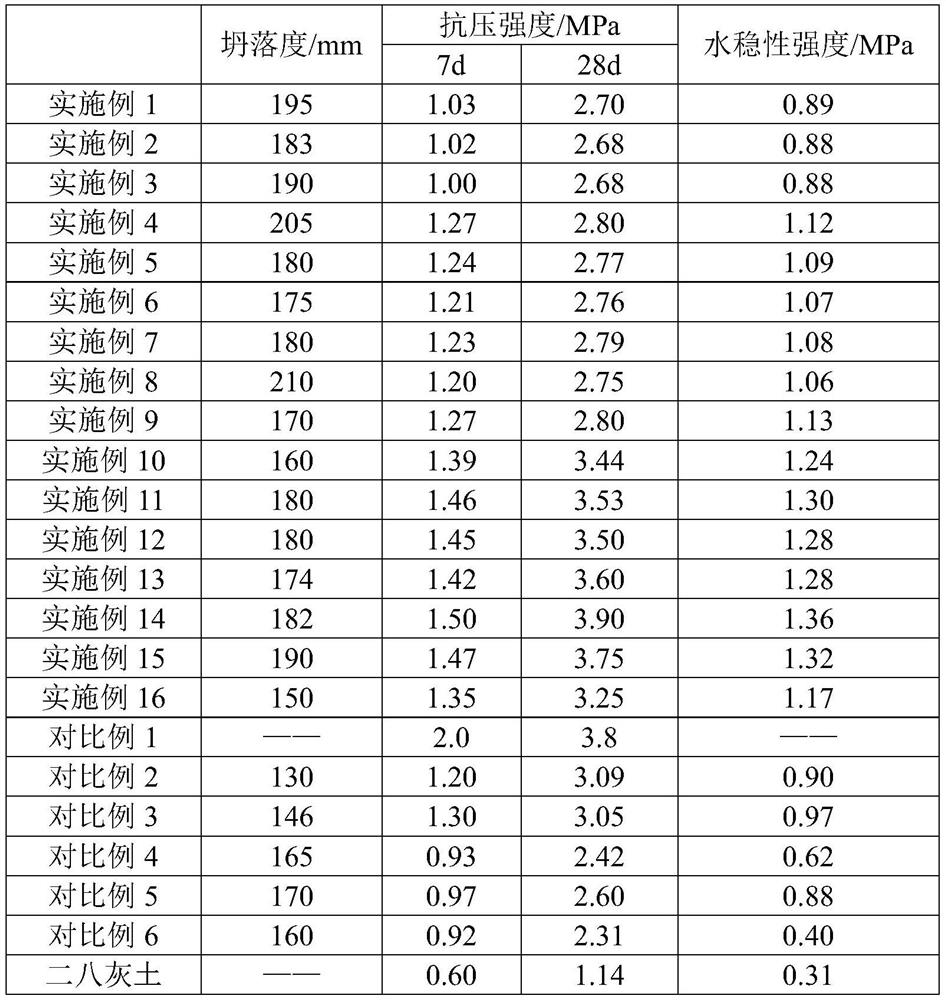

Examples

Embodiment 1

[0043] A kind of fluid solidification regeneration mixture, it is prepared through following specific operation steps:

[0044] According to the dosage of each raw material in Table 1, the cementitious materials: cement and fly ash are added to the primary mixing tank through screw metering according to the mixing ratio; the recycled materials are batched through the batching bin and transported to the primary mixing tank through the conveyor belt. tank; the mixing water is added in two ways according to the ratio and dosage, one way is the water adding system of the first mixing tank, and the second way is the water adding system of the second mixing tank, and the mixing amount of the two ways is controlled by the flow meter. Half of the amount of water; after the cementitious material, recycled material and all the water are added to the primary mixing tank, the primary mixing is carried out to obtain the primary mixing material;

[0045] The primary mixing material is conve...

Embodiment 2-6

[0047] The preparation method of the fluid solidified recycled mixture of Examples 2-6 is exactly the same as that of Example 1, the difference is that the types and dosages of various raw materials are different, and the admixture is added by external mixing, and is not included in the fluid state Among the sum of the raw materials of the solidified recycled mixture, see Table 1 for details; see Table 1 for the sand content of redundant soil in each embodiment.

[0048] The raw material dosage (kg) of the fluid solidified regeneration mixture of table 1 embodiment 1-6

[0049]

Embodiment 7-16

[0051] The fluid solidified regenerated mixture of embodiment 7-16, its preparation method is exactly the same as embodiment 1, and difference is that each raw material type and dosage are different, see table 2 for details; Redundant soil in each embodiment The sand content is 72%.

[0052] The raw material dosage (kg) of the fluid solidification regeneration mixture of table 2 embodiment 7-16

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com