Prefabricated steel-encased concrete spliced column and construction process

A technology for reinforced concrete columns and concrete columns, which can be applied to columns, pier columns, pillars, etc., can solve the problems of environmental pollution engineering quality, waste of materials, and a large number of templates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

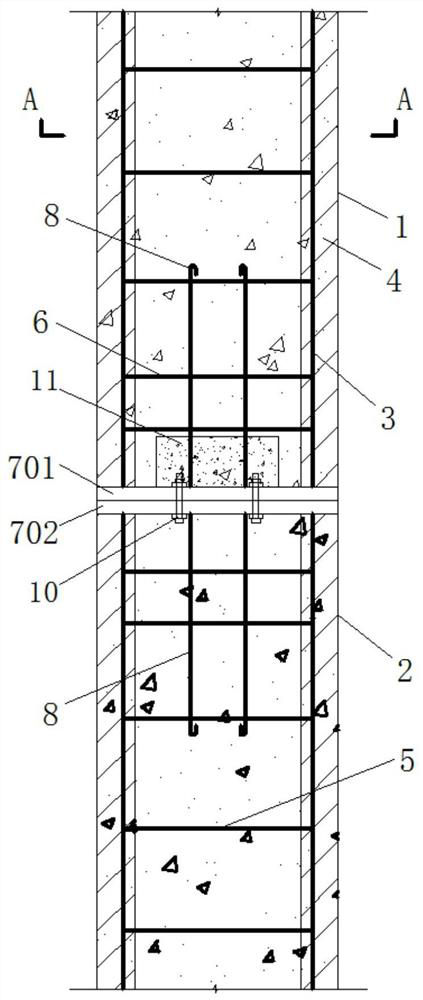

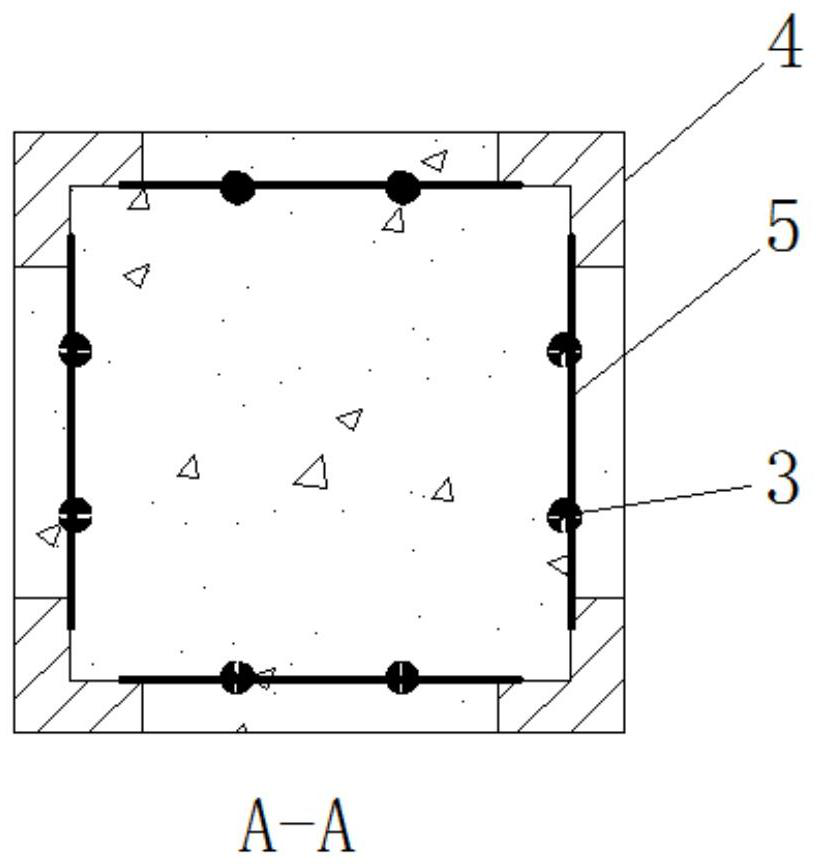

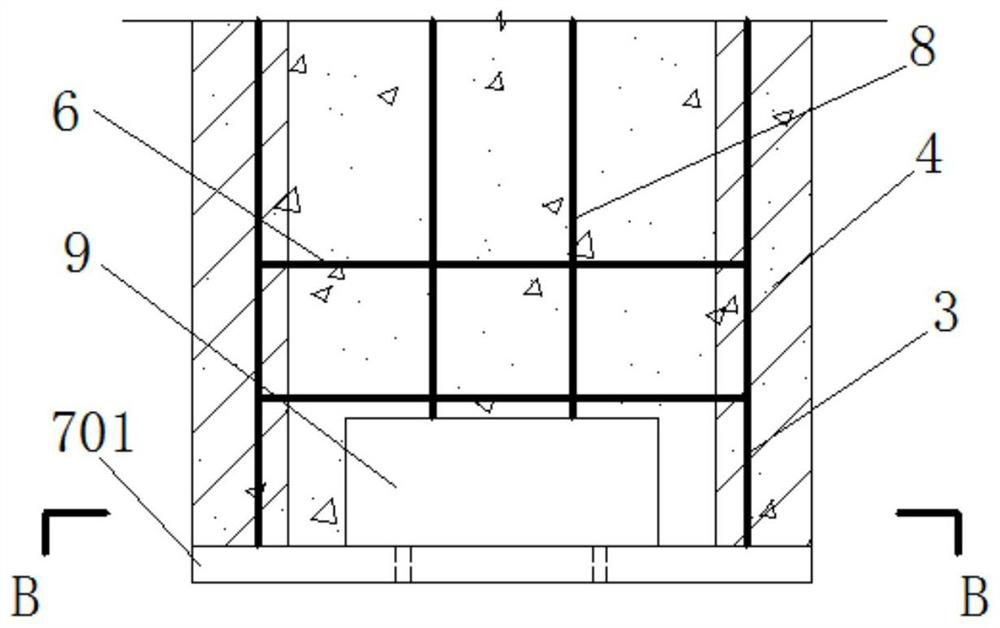

[0088] Such as Figure 1 to Figure 6 As shown, a prefabricated outsourcing steel concrete splicing column includes an upper column section 1 and a lower column section 2, the lower column section 2 and the upper column section 1 are prefabricated outsourcing steel concrete columns, and the lower column section 2 includes steel bars Skeleton, outsourcing angle steel 4, anchoring steel bar 8 and lower end plate 702, the lower surface of the lower end plate 702 is welded with the longitudinal bar 3 of the steel bar skeleton, and an encrypted stirrup bar 6 is arranged between the adjacent stirrup bars 5 near the lower end plate 702 , the lower surface of the lower end plate 702 is welded with anchoring steel bars 8 positioned at the inside of the steel bar skeleton, and the four corners of the lower end plate 702 are welded with outsourcing angle steel 4 located at the outside of the steel bar skeleton, and the inner surfaces of the two arms of the outsourcing angle steel 4 are all...

Embodiment 2

[0097] Such as Figure 7 to Figure 12 As shown, a prefabricated outsourcing steel concrete splicing column includes an upper column section 1 and a lower column section 2, the lower column section 2 is a prefabricated outsourcing rigid concrete column, the upper column section 1 is a prefabricated reinforced concrete column, and the lower column section 2 includes steel bar skeleton, outsourcing angle steel 4, anchoring steel bar 8 and lower end plate 702, the lower surface of the lower end plate 702 is welded with the longitudinal bar 3 of the steel bar skeleton, and encryption is arranged between the adjacent stirrup bars 5 near the lower end plate 702 Stirrups 6, the lower surface of the lower end plate 702 is welded with anchoring bars 8 located inside the steel bar skeleton, and the four corners of the lower end plate 702 are welded with outsourcing angle steel 4 located outside the steel bar skeleton, and the inner surfaces of the two arms of the outsourcing angle steel 4...

Embodiment 3

[0106] Such as Figure 13 to Figure 16 As shown, a prefabricated steel-concrete splicing column with outsourcing includes an upper column section 1 and a lower column section 2. The lower column section 2 and the upper column section 1 have the same structure, and both are prefabricated outsourcing steel-concrete columns, including a steel skeleton, The outsourcing angle steel 4 and the anchoring steel bar 8, the outsourcing angle steel 4 is evenly distributed at four points along the circumferential direction, the geometric center surrounded by the outsourcing angle steel 4 is provided with a reinforcement skeleton, and the inner surfaces of the two arms of the outsourcing angle steel 4 are connected with the hoop of the reinforcement skeleton The two ends of the reinforcement 5 are welded, and an encrypted stirrup 6 is arranged between two adjacent stirrups 5 of the reinforcement skeleton, and an anchor reinforcement 8 is arranged on the inside of the reinforcement skeleton, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com