Copper alloy plate strip for use in led lead frame

A technology of copper alloy and lead frame, applied in the direction of metal/alloy conductors, metal layered products, root rods/rods/wires/strip conductors, etc., which can solve the problems of high brightness of LED components approaching the limit and component cost increase, etc. Achieve the effect of improving reflectivity and improving heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

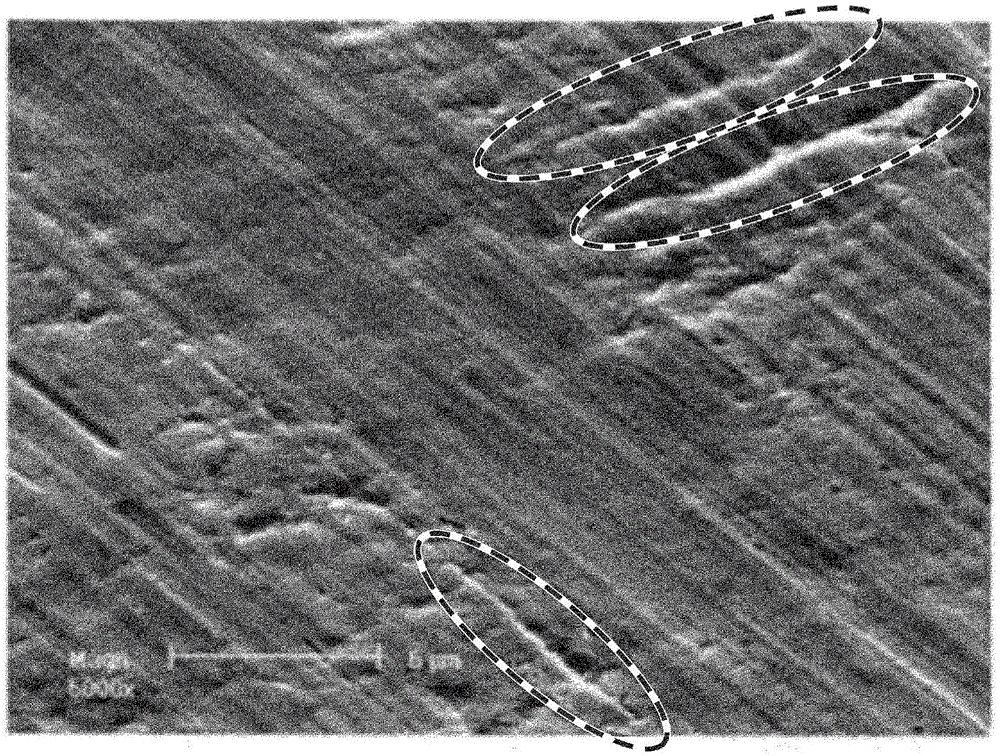

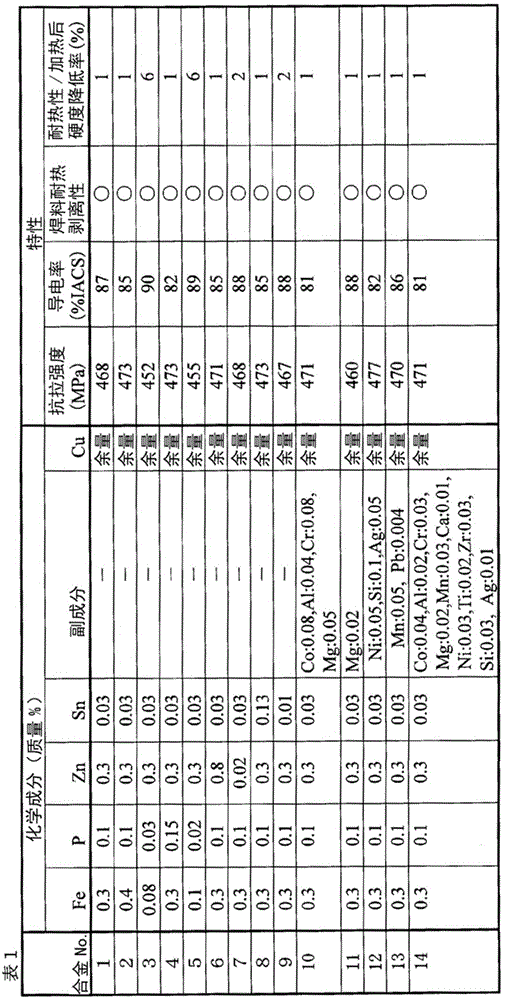

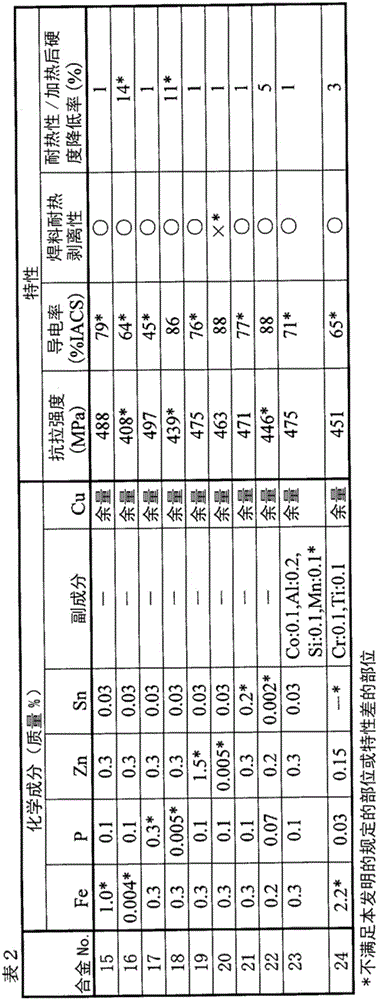

Embodiment 1

[0045] Copper alloys (alloy Nos. 1 to 24) with the compositions shown in Tables 1 and 2 were melted under a charcoal coating in the atmosphere using a small electric furnace to melt an ingot with a thickness of 50 mm, a width of 80 mm, and a length of 180 mm. The surface and the back surface of the produced ingot were subjected to 5 mm face-cutting, followed by homogenization treatment at 950° C., followed by hot rolling to form a 12 mmt-thick plate, which was quenched. The front and back faces of this board were each face-cut by about 1 mm. For these plates, after repeated cold rolling and precipitation annealing at 500-550°C for 2-5 hours, the final cold-rolling was performed at a processing rate of 40% using a mirror-finished 50mm-diameter saron ceramic roll. A copper alloy strip with a thickness of 0.2mm and a width of 180mm is used as the test material. The lubricating oil described above is used in the finish cold rolling, and the rotational speed and drawing tension of...

Embodiment 2

[0060]Copper alloys (alloy Nos. 1, 2, 3, 10, 15, and 24) with the compositions shown in Tables 1 and 2 were melted in a small electric furnace under a charcoal coating in the atmosphere, and an ingot with a thickness of 50 mm, a width of 80 mm, and a length of 180 mm was melted. . The surface and the back surface of the produced ingot were subjected to 5 mm face-cutting, followed by homogenization treatment at 950° C., followed by hot rolling to form a 12 mmt-thick plate, which was quenched. The front and back faces of this board were each face-cut by about 1 mm. For these plates, after repeated cold rolling and precipitation annealing at 500-550°C for 2-5 hours, the final cold-rolling was performed at a processing rate of 40% using a mirror-finished 50mm-diameter saron ceramic roll. A copper alloy strip with a thickness of 0.2mm and a width of 180mm is used as the test material. In the final cold rolling, adjust the surface roughness of the salen ceramic roll and the rotati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com