High-strength fire-resistant paper surface gypsum board and preparation method thereof

A paper-faced gypsum board and refractory technology, which is applied in the direction of chemical instruments and methods, paper/cardboard layered products, hydraulically settable material layered products, etc., can solve the problem of not improving the strength and fire resistance of the board core, and increasing the production of gypsum boards Cost and other issues, to achieve the effect of excellent mechanical properties, excellent fire resistance, excellent fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

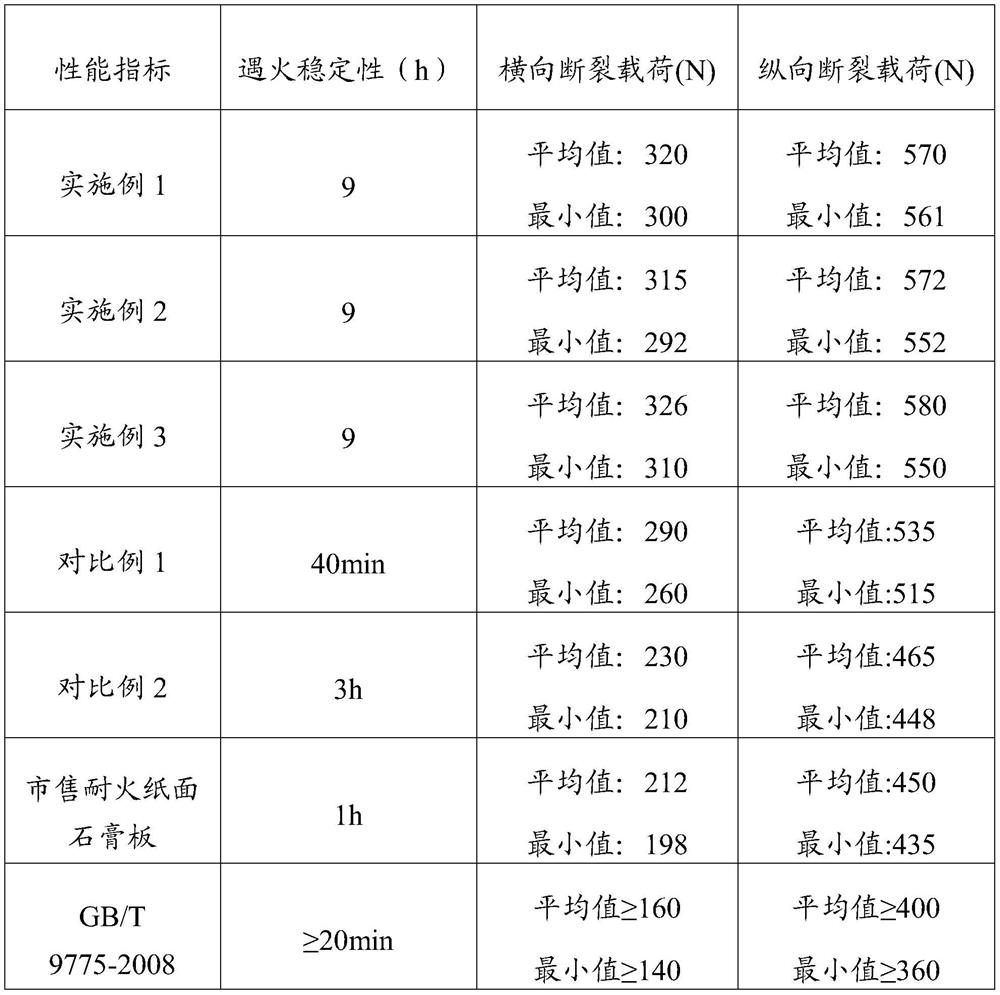

Examples

Embodiment 1

[0041] Among the raw materials of the gypsum board prepared in this example, the mass ratio of the mullite whiskers in the refractory material to the alkali-free glass fiber is 1:3, and the water reducer is polycarboxylate produced by Sika Water reducer 530P, the foaming agent is sodium lauryl sulfate produced by Futeng Chemical Industry and silicone resin polyether emulsion produced by Damai Chemical Industry, the mass ratio of the two is 1:0.8;

[0042] The length of the mullite whisker is 5 μm, and the aspect ratio is 20; the length of the glass fiber is 6 mm, and the single filament diameter of the glass fiber is 5 μm;

[0043] The specific surface area of the gypsum clinker is 3200cm 2 / g;

[0044] The paper surface gypsum board that the present embodiment makes, concrete preparation steps are as follows:

[0045] 1) Weigh 100 parts of gypsum clinker, 0.1 part of water reducing agent, 0.3 part of modified tapioca starch, 0.03 part of foaming agent, 1.5 parts of refrac...

Embodiment 2

[0050] The paper-faced gypsum board prepared in this example, among its raw materials, the mass ratio of mullite whiskers in the refractory material to alkali-resistant glass fibers is 1:4, and the water reducer is UNFJW- 1 naphthalene-based water reducer, the foaming agent is sodium dodecylbenzenesulfonate produced by Futeng Chemical Industry and silicone resin polyether emulsion produced by Damai Chemical Industry, the mass ratio of the two is 1:1;

[0051] The length of the mullite whisker is 8 μm, and the aspect ratio is 25; the length of the glass fiber is 10 mm, and the diameter of the monofilament of the glass fiber is 5 μm;

[0052] The specific surface area of the gypsum clinker is 3800cm 2 / g;

[0053] The paper surface gypsum board that the present embodiment makes, concrete preparation steps are as follows:

[0054] 1) Weigh 100 parts of gypsum clinker, 0.15 parts of water reducer, 0.5 part of modified corn starch, 0.04 parts of foaming agent, 3.2 parts of refr...

Embodiment 3

[0059] The paper surface gypsum board prepared in this example, among its raw materials, the mass ratio of mullite whiskers in the refractory material to medium-alkali glass fiber is 1:4, and the water reducing agent is sodium lignosulfonate produced by Zouyang Chemical Industry Water reducing agent, described whipping agent is the silicone resin polyether emulsion that the fatty alcohol polyoxyethylene ether sodium sulfate produced by Bangnuo Biotechnology Co., Ltd. and Damai Chemical Co., Ltd. produce, and the mass ratio of the two is 1:1;

[0060] The length of the mullite whisker is 10 μm, and the aspect ratio is 30; the length of the glass fiber is 20 mm, and the diameter of the monofilament of the glass fiber is 6 μm;

[0061] The specific surface area of the gypsum clinker is 4000cm 2 / g;

[0062] The paper surface gypsum board that the present embodiment makes, concrete preparation steps are as follows:

[0063] 1) Weigh 100 parts of gypsum clinker, 0.2 part of wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com