Method for rolling pure titanium rod and wire

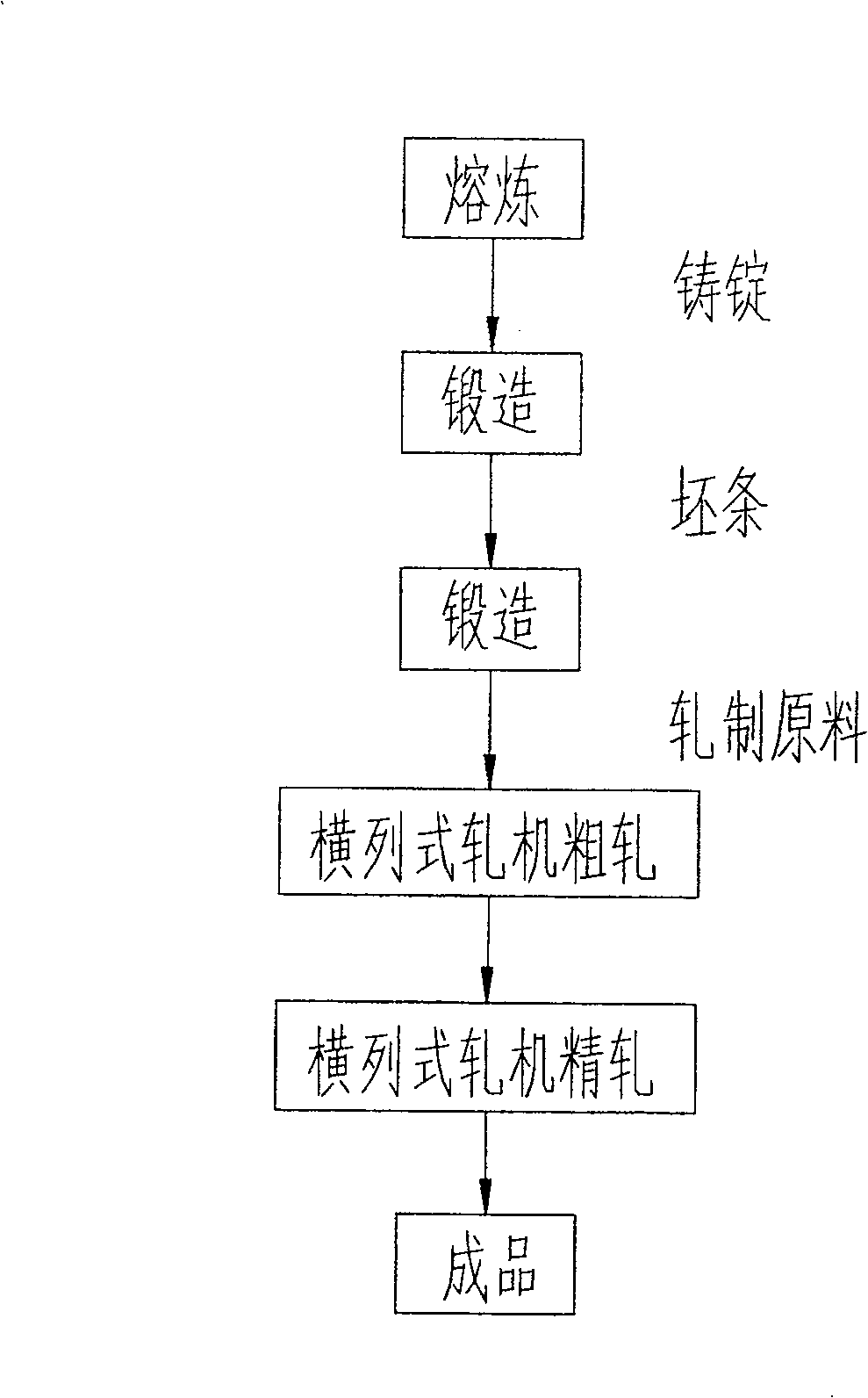

A bar and wire rod and pure titanium technology, which is applied to the processing field of pure titanium rod and wire rod, can solve the problems of uneven structure, low rolling speed and high energy consumption, and achieve the effects of excellent structure performance, improved production efficiency and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

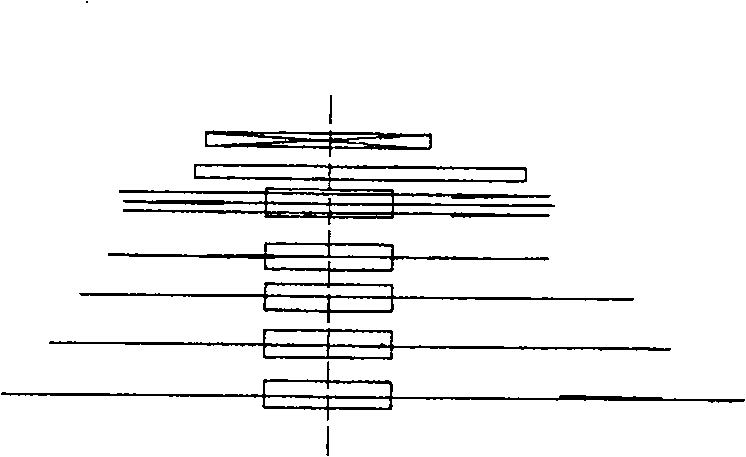

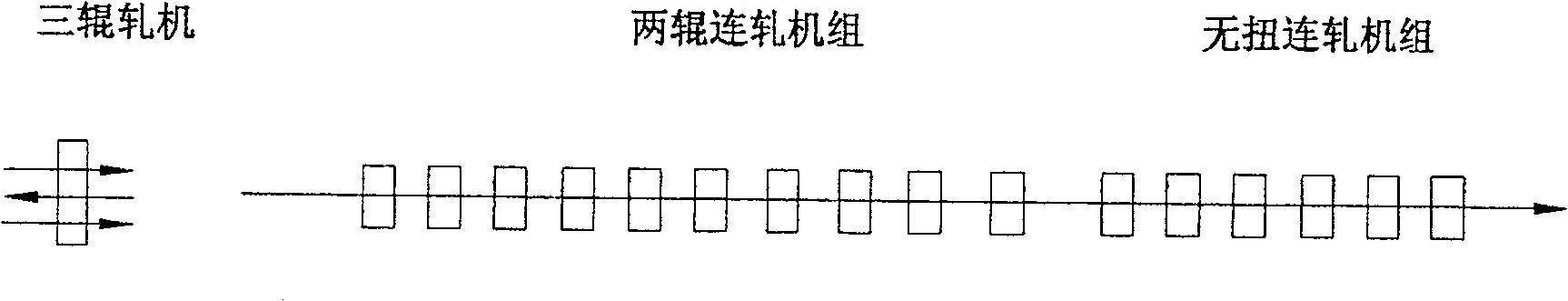

[0024] Three-roll rolling mill: such as image 3 As shown, the three-roll rolling mill is composed of a Φ100mm billet heating furnace, a three-roll rolling mill, front and rear raceways, and a cooling bed. The Φ100mm billet heating furnace adopts electric heating, automatic control, digital display, record printing, and the temperature of the pure titanium billet in the heating furnace is controlled at 600-850°C. The pass type of the three-roll rolling mill is ellipse-square, ellipse-round pass system, the average elongation coefficient of the pass is 1.1-1.5, and the final rolling temperature is controlled at 500-850°C. The raceway can meet the rolling requirements of Φ80-50mm rods and billets with a single weight less than 100kg, and the cooling bed can meet the cooling requirements of pure titanium rods.

[0025] The three-roll rolling mill can produce Φ80-50mm round bars, square bars and other special-shaped bars. The maximum unit weight of bars is 100kg; it can also prod...

Embodiment 2

[0027] Two-roll continuous rolling mill: see image 3 As shown, the two-roll continuous rolling unit is composed of a Φ50mm billet heating furnace, a continuous rolling unit, a special guide, a raceway, a cooling bed, flying shears, and a take-up coiler. The Φ50mm billet heating furnace adopts electric heating, automatic control, digital display, record printing, and the temperature accuracy of the pure titanium billet in the heating furnace is controlled at ±10°C. The pass pattern of the two-roll tandem rolling mill adopts the ellipse-square, ellipse-round pass system, the average elongation coefficient of the pass is 1.1-1.4, and the final rolling temperature is controlled at 600-850°C. All rolling mills are driven by frequency conversion motors, and there are detachable rolling special guides between the front and rear stands in the middle pass, so that the rolled pieces rolled by the previous stand can be easily thrown out and twisted 90° for the next machine. The frame b...

Embodiment 3

[0030] Twist-free tandem mill: The tandem-twist mill is composed of a twist-free rolling mill, a winding coiler and a moving cooling bed. The pass of the twist-free tandem rolling mill is an ellipse-circle pass system, the average elongation coefficient of each pass is 1.05-1.4, the reduction of area of each pass is less than 20%, the final rolling temperature is controlled at 500-850°C, and the dimensional accuracy of the finished wire rod is controlled. Improve finished surface quality. The coiling machine can quickly coil the wire blank into a coil, and the moving cooling bed can cool the coil and send it out automatically. The twist-free tandem rolling unit can produce Φ8-6mm wire billets with a unit weight of 100kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com