Combined type special hanger insulation tool for safety belt

A technology for insulating tools and seat belts, which is applied to the field of insulating tools for combined seat belt special hangers, can solve the problems of reduced service life, low temperature and cold resistance performance, etc., and achieves improved strength and modulus, stable performance, and improved availability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

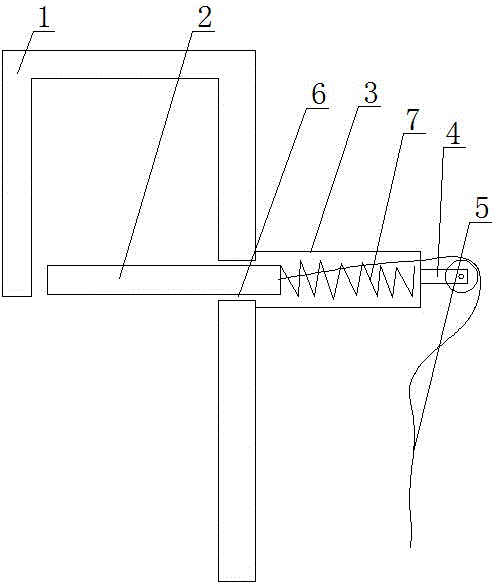

[0017] Embodiment 1: as figure 1 As shown, a combined safety belt special hanger insulation tool includes a hook body, and the opening of the hook body 1 is provided with a self-locking mechanism. The self-locking mechanism includes a cylinder arranged on the hook body 1. The hook body 1 is provided with a through hole for the sliding rod in the cylinder to protrude. The sliding rod 2 is connected to the bottom of the cylinder body 3 through a spring 7. The end of the cylinder body 6 is provided with a round hole for the stay cord 5 to pass through, and the cylinder body is provided with a pulley 4 . The insulating layer is prepared from the following raw materials by weight: 30 parts of epoxy resin, 2 parts of polyvinyl chloride, 25 parts of polypropylene resin, 8 parts of phenolic resin, 9 parts of nylon fiber, 3 parts of curing agent, 6 parts of zeolite powder, 5 parts of polyglycolic acid, 2 parts of phthalic anhydride. The raw materials and parts by weight of the curing...

Embodiment 2

[0018] Embodiment 2: as figure 1 As shown, a combined safety belt special hanger insulation tool includes a hook body, and the opening of the hook body 1 is provided with a self-locking mechanism. The self-locking mechanism includes a cylinder arranged on the hook body 1. The hook body 1 is provided with a through hole for the sliding rod in the cylinder to protrude. The sliding rod 2 is connected to the bottom of the cylinder body 3 through a spring 7. The end of the cylinder body 6 is provided with a round hole for the stay cord 5 to pass through, and the cylinder body is provided with a pulley 4 . Both the hook body and the sliding rod are provided with insulating layers. The insulating layer is prepared from the following raw materials by weight: 30 parts of epoxy resin, 2 parts of polyvinyl chloride, 25 parts of polypropylene resin, 8 parts of phenolic resin, 9 parts of nylon fiber, 3 parts of curing agent, 6 parts of zeolite powder, 5 parts of polyglycolic acid, 2 part...

Embodiment 3

[0019] Embodiment 3: as figure 1 As shown, a combined safety belt special hanger insulation tool includes a hook body, and the opening of the hook body 1 is provided with a self-locking mechanism. The self-locking mechanism includes a cylinder arranged on the hook body 1. The hook body 1 is provided with a through hole for the sliding rod in the cylinder to protrude. The sliding rod 2 is connected to the bottom of the cylinder body 3 through a spring 7. The end of the cylinder body 6 is provided with a round hole for the stay cord 5 to pass through, and the cylinder body is provided with a pulley 4 . The insulating layer is prepared from the following raw materials in parts by weight: 50 parts of epoxy resin, 4 parts of polyvinyl chloride, 30 parts of polypropylene resin, 15 parts of phenolic resin, 12 parts of nylon fiber, 5 parts of curing agent, 10 parts of zeolite powder, 8 parts of polyglycolic acid, 4 parts of phthalic anhydride. The insulating layer material also incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com