Preparation method of composite ceramic coating

A composite ceramic and coating technology, which is applied in the field of surface coating, can solve the problems of limited application and promotion, high brittleness of materials, and difficulty in achieving material compactness, etc., and achieves the effect of simple spraying process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

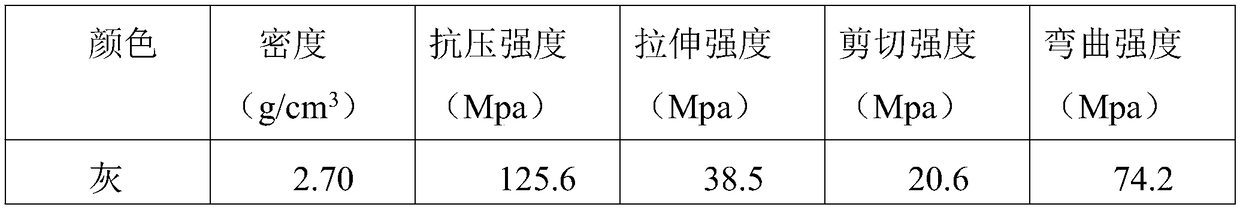

Embodiment 1

[0020] Silicon carbide micropowder, nano-tungsten powder, ultrafine graphite powder and sodium carboxymethyl cellulose are ground and mixed in a mortar according to the ratio of 100:3:3:6 by weight; add 100% deionized water and 2 % dispersant, in a planetary ball mill, carry out wet ball milling at a speed of 1500r / min for 18 hours to obtain a uniform suspension; after drying and pulverizing the above suspension, sieve it with a 100-mesh sieve to obtain a mixed powder; The powder is melted at a high temperature of 1500°C for 1.0h to form a molten particle flow, which is sprayed on the surface of the metal substrate at a speed of 1200m / s to obtain a silicon carbide / graphite composite ceramic coating. Table 1 shows the performance evaluation results of the nano-tungsten powder reinforced silicon carbide / graphite composite ceramic coating obtained in this example.

[0021]

Embodiment 2

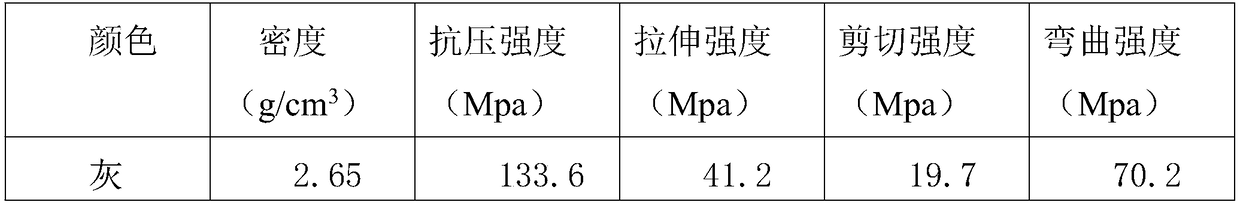

[0023] Grind and mix silicon carbide micropowder, nano-tungsten powder, ultrafine graphite powder and potassium water glass in a mortar according to the ratio of 100:4:3:8 by weight; add 120% deionized water and 3% dispersing In a planetary ball mill, perform wet ball milling at a speed of 1800r / min for 20 hours to obtain a uniform suspension; after drying and pulverizing the above suspension, sieve it with a 200-mesh sieve to obtain a mixed powder; put the above powder in Melt at a high temperature of 1500°C for 1.5 hours to form a molten particle flow, which is sprayed on the surface of the metal substrate at a speed of 1200m / s to obtain a silicon carbide / graphite composite ceramic coating. Table 2 shows the performance evaluation results of the nano-tungsten powder reinforced silicon carbide / graphite composite ceramic coating obtained in this example.

[0024]

Embodiment 3

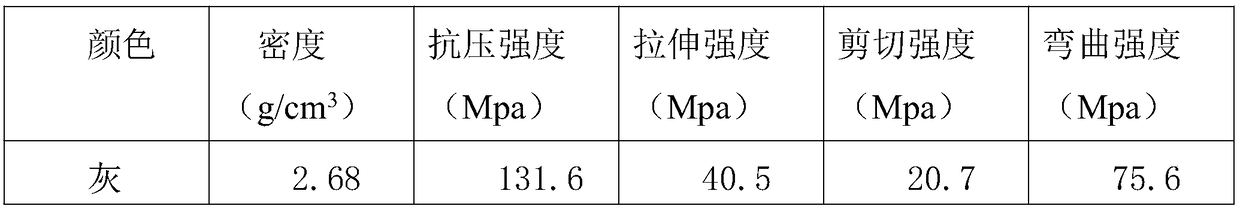

[0026] Grind and mix silicon carbide micropowder, nano-tungsten powder, ultrafine graphite powder and hydroxyethyl cellulose in a mortar according to the ratio of 100:6:5:8 by weight; add 100% deionized water and 3% In a planetary ball mill, perform wet ball milling at a speed of 1500r / min for 19 hours to obtain a uniform suspension; after drying and pulverizing the above suspension, sieve it with a 100-mesh sieve to obtain a mixed powder; mix the above powder The body is melted at a high temperature of 1500°C for 1.5 hours to form a molten particle flow, which is sprayed on the surface of the metal substrate at a speed of 1800m / s to obtain a silicon carbide / graphite composite ceramic coating. Table 3 shows the performance evaluation results of the nano-tungsten powder reinforced silicon carbide / graphite composite ceramic coating obtained in this example.

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com