Hyperbranched polyethyleneimine doped and modified acrylic emulsion and preparation method thereof

A technology of polyethyleneimine and acrylic emulsion, which is applied in the direction of coating, etc., and can solve the problems of high crosslinking density, poor scratch resistance, and large loss of coating resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

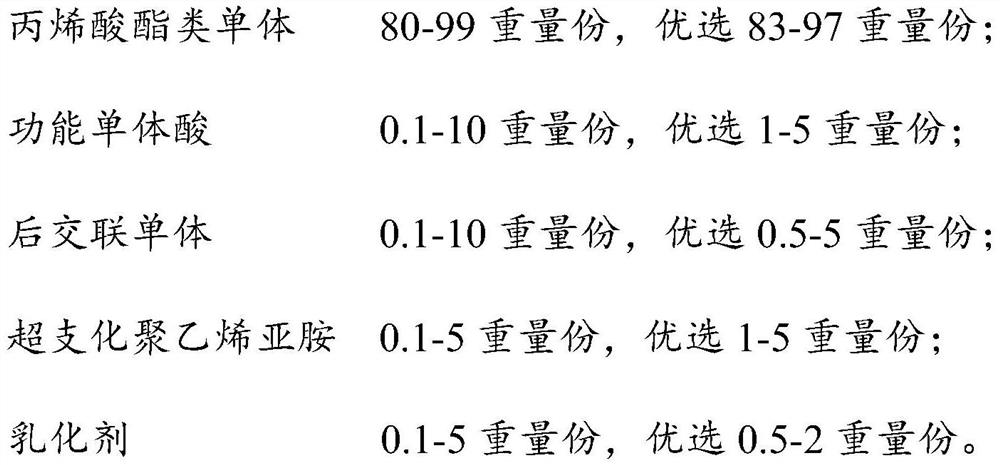

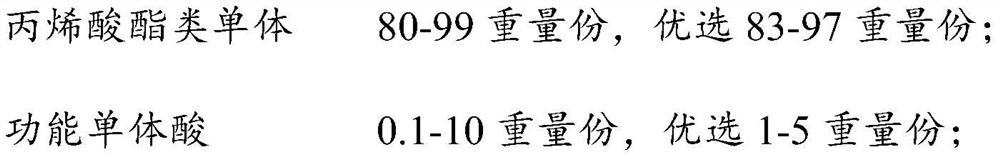

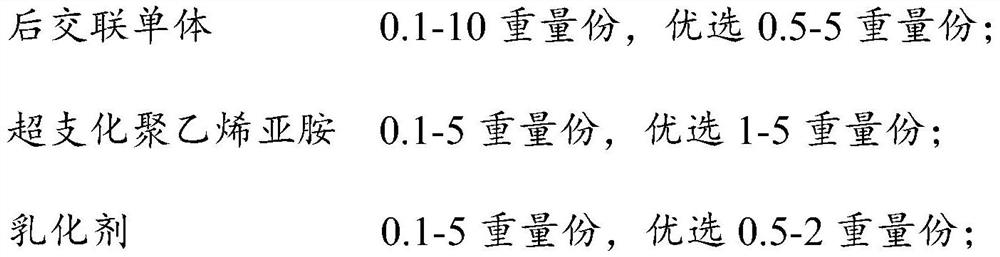

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Preparation of Hyperbranched Polyethyleneimine Doped Modified Acrylic Emulsion 1 (hereinafter referred to as "Acrylic Emulsion 1")

[0040] The preparation of hyperbranched polyethyleneimine doped modified acrylic acid emulsion 1 in the present embodiment comprises the following steps:

[0041] Step 1): Preparation of Acrylic Emulsion:

[0042] 1.1) Dissolve 90% SDS (1.8g) of the total weight of SDS in 30g water, then add 53gMMA (methyl methacrylate), 30g BA (butyl acrylate), 5gDAAM (diacetone acrylamide) and 5g MAA in sequence (Methacrylic acid), stirred in an emulsification tank to form a pre-emulsion.

[0043] 1.2) Dissolve the remaining SDS (sodium dodecyl sulfate, 0.2 g) with 66 g of deionized water and add it to the reactor, blow nitrogen into the reactor to exhaust the air in the reactor, and keep the reaction temperature at 85°C.

[0044] From step 1.1), the pre-emulsion that takes out 4% (accounting for the total mass of pre-emulsion) drops into th...

Embodiment 2-8

[0049] Example 2-8 Preparation of hyperbranched polyethyleneimine doped modified acrylic emulsion 2-8 (hereinafter referred to as "acrylic emulsion 2-8")

[0050] The preparation of acrylic emulsion 2-8 adopts the method similar to that of acrylic emulsion 1, the only difference is that the amount of each raw material is as shown in Table 2-1.

Embodiment 9

[0062] Example 9 Preparation of water-based wooden door paint

[0063] The acrylic emulsion prepared in Example 1 was prepared according to the water-based wooden door paint coating formulation table as shown in Table 3, and the water-based wooden door paint coating 1 was prepared according to the following method.

[0064] Table 3 Waterborne Wooden Door Paint Coating Formulation Table

[0065]

[0066] Note: raw materials that do not indicate the manufacturer can be used as long as they are of the same type, and Vesmody is a brand name

[0067] According to the formula in Table 3, 80g of the acrylic emulsion prepared in Example 1 and 14.35g of water were sequentially added to the dispersion tank, and stirred at 500r / min for 10min. Then add 0.05g AMP-95, 0.2g BYK-024, 1.0g BYK-420, 2.0g dipropylene glycol methyl ether, 2.0g dipropylene glycol butyl ether and 0.4g U604 in sequence, increase the speed to 800r / min, and stir for 20min. Get water-based wooden door paint.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com