Rubber material for automobile transmission belt and preparation method therefor

A technology of rubber materials and conveyor belts, applied in the field of rubber materials, can solve the problems of poor stretch resistance and inability to take care of both at the same time, and achieve the effect of combining hardness and stretch resistance, low cost, and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

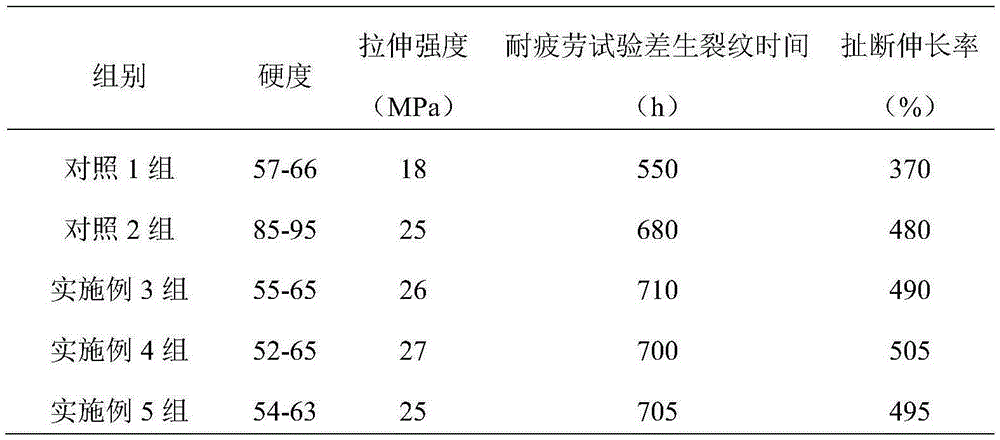

Examples

Embodiment 1

[0022] Party:

[0023] 60 parts of acrylic resin, 40 parts of styrene-butadiene rubber, 50 parts of natural rubber, 1 part of silane coupling agent, 2 parts of sulfur, 1 part of zinc oxide, 2 parts of cumene hydrogen peroxide, 0.1 part of anti-aging agent, tetramethyl disulfide 0.3 parts of thiuram, 30 parts of isopropanol.

[0024] The molecular weight of the acrylic resin is 80000.

[0025] Preparation:

[0026] (1) Get silane coupling agent, zinc oxide and cumene hydroperoxide, join in the isopropanol, make initial mixture;

[0027] (2) Add acrylic resin, styrene-butadiene rubber and natural rubber to the above initial mixture, then add anti-aging agent and tetramethylthiuram disulfide, and stir at 2000r / min for 20 minutes at 40°C to obtain masterbatch;

[0028] (3) Molding the above-mentioned masterbatch, and vulcanizing it with sulfur.

Embodiment 2

[0030] Party:

[0031] 60 parts of acrylic resin, 60 parts of styrene-butadiene rubber, 70 parts of natural rubber, 9 parts of titanate coupling agent, 6 parts of sulfur, 7 parts of zinc oxide, 8 parts of cumene hydrogen peroxide, 0.5 parts of anti-aging agent, disulfide 0.7 parts of tetramethylthiuram, 40 parts of isopropanol.

[0032] The molecular weight of the acrylic resin is 100,000.

[0033] Preparation:

[0034] (1) Take titanate coupling agent, zinc oxide and cumene hydroperoxide, and add them to isopropanol to make initial mixture;

[0035] (2) Add acrylic resin, styrene-butadiene rubber and natural rubber to the above initial mixture, then add anti-aging agent and tetramethylthiuram disulfide, stir at 4000r / min for 40 minutes at 60°C to obtain masterbatch;

[0036] (3) Molding the above-mentioned masterbatch, and vulcanizing it with sulfur.

Embodiment 3

[0038] Party:

[0039] 60 parts of acrylic resin, 50 parts of styrene-butadiene rubber, 60 parts of natural rubber, 5 parts of aluminate coupling agent, 4 parts of sulfur, 4 parts of zinc oxide, 5 parts of cumene hydrogen peroxide, 0.3 parts of anti-aging agent, disulfide 0.5 parts of tetramethylthiuram, 35 parts of isopropanol.

[0040] The molecular weight of the acrylic resin is 90,000.

[0041] Preparation:

[0042] (1) Get aluminate coupling agent, zinc oxide and cumene hydroperoxide, join in the isopropanol, make initial mixture;

[0043] (2) Add acrylic resin, styrene-butadiene rubber and natural rubber to the above initial mixture, then add anti-aging agent and tetramethylthiuram disulfide, stir at 3000r / min for 30 minutes at 50°C to obtain masterbatch;

[0044] (3) Molding the above-mentioned masterbatch, and vulcanizing it with sulfur.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com