Protective film applied to curved display screen

A display and protective film technology, applied in pressure-sensitive films/sheets, film/sheet-like adhesives, coatings, etc., can solve the problems of low hardness, poor durability, and high brittleness of products, and achieve both hardness and flexibility, solve edge lift, improve the effect of fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

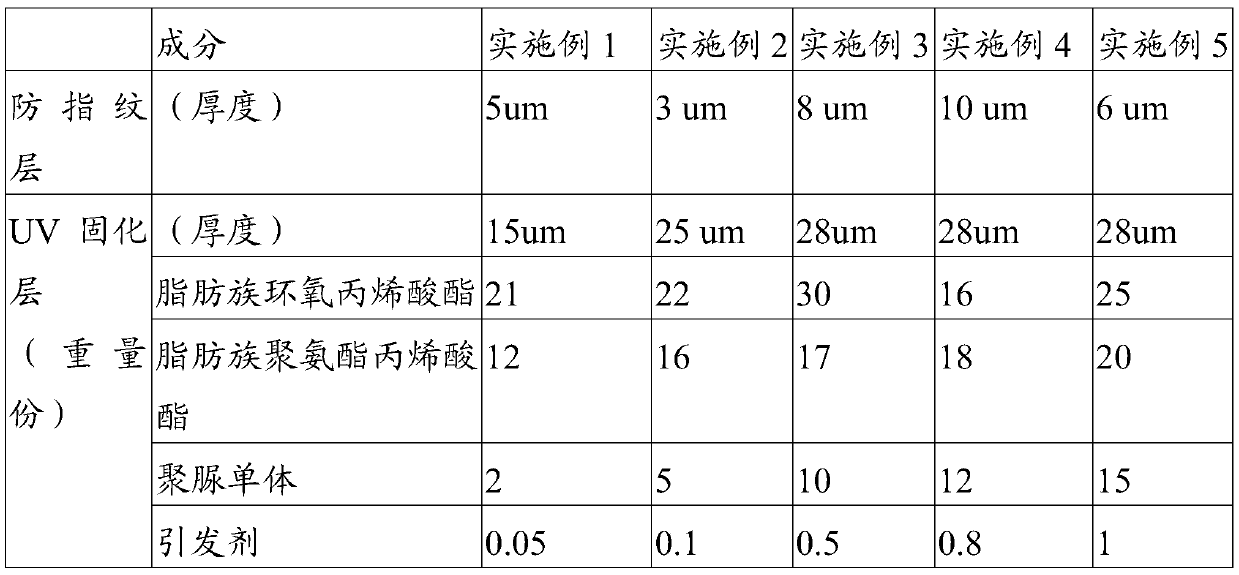

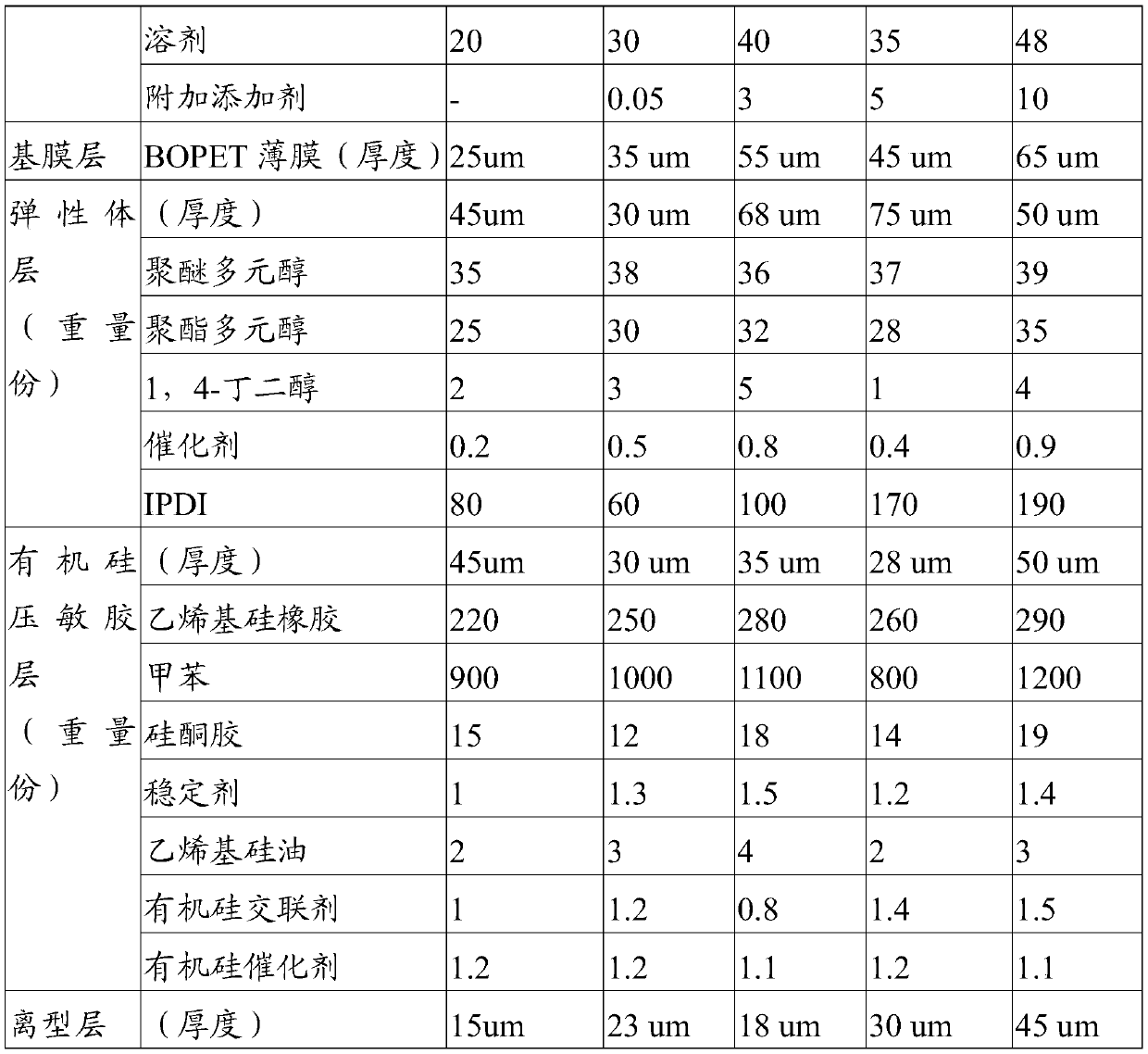

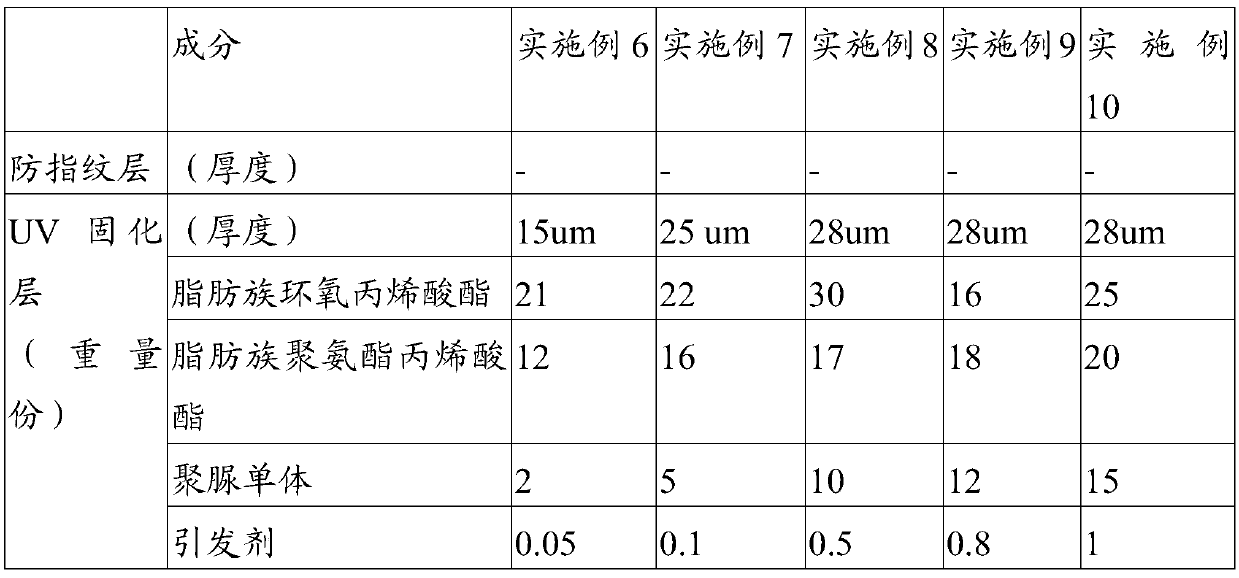

[0061] Further, the present invention also provides a method for preparing the UV curable layer, the preparation steps are as follows:

[0062] A. Add aliphatic epoxy acrylate, aliphatic urethane acrylate, polyurea monomer and solvent in a reaction kettle equipped with a stirrer, thermometer, condenser and feed tank, and stir;

[0063] B. Add additional additives to the reaction kettle, the temperature of the reaction kettle is 40-60°C, stop stirring when the solution is colorless and transparent, and store it in a black light-proof container.

[0064] In the protective film applied to curved display screens provided by the present invention, the UV curing layer adopts low-viscosity long-chain urethane acrylate and epoxy acrylate as oligomers, so that the UV curing layer has high flexibility and adhesion; The addition of modified polyurea monomer makes the UV curable layer have the advantages of impact resistance and yellowing resistance.

[0065] 2. Basement membrane layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com