Wearing-resistant composite material fan coal mill hitting plate

A technology for fan coal pulverizers and composite materials, which is applied in grain processing and other directions, can solve the problems of troublesome replacement of protective linings, easy wear and tear of impact plates, and short service life, and achieves improved service life, convenient replacement, and improved wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

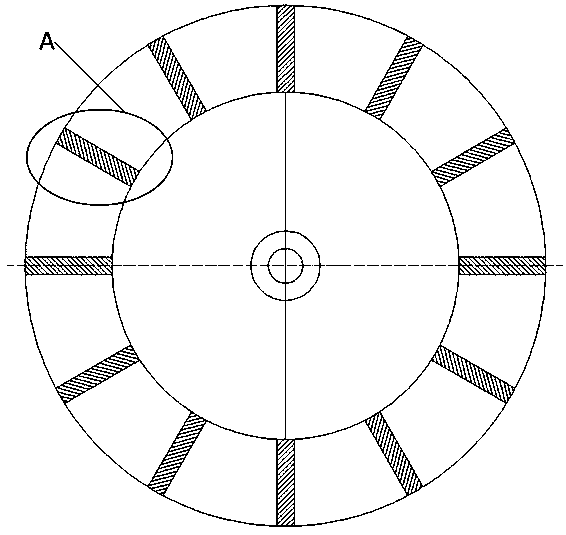

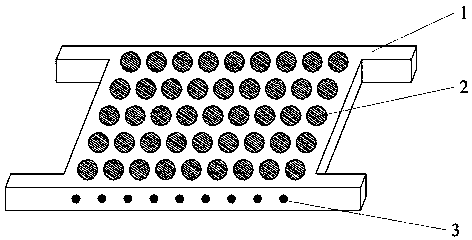

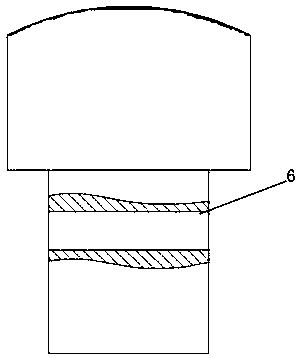

[0032] A new type of wear-resistant composite material fan coal mill strike plate, such as figure 1 , 2 , 3, 4, and 5, including a metal base 1, a composite material insert 2, a pin 3, and a rubber ring 4. The metal base is evenly opened with through holes and pin holes I, and one end of the composite material insert 2 protrudes, and the other end It is a stepped shaft, one end of the stepped shaft is covered with a rubber ring 4, the composite material insert 2 is provided with a pin hole II, and the rubber ring 4 is provided with a pin hole III, the composite material insert 2 is embedded in the metal base 1, and the pin 3 passes through it. Through the pin hole I on the metal base 1, the pin hole II on the composite material insert 2, and the pin hole III on the rubber ring 4, the section of the protruding end of the composite material insert 2 is circular in shape, and the metal base 1 adopts the model The high chromium cast iron of KmTBCr15Mo is used as the matrix materi...

Embodiment 2

[0039] A new type of wear-resistant composite material fan coal mill strike plate, including a metal base 1, a composite material insert 2, a pin 3, and a rubber ring 4, the metal base is evenly opened with through holes and pin holes I, and the composite material insert 2 One end protrudes, the other end is a stepped shaft, and one end of the stepped shaft is covered with a rubber ring 4, and the composite material insert 2 has a pin hole II, and the rubber ring 4 has a pin hole III, and the composite material insert 2 is embedded in the metal matrix 1 Above, the pin 3 passes through the pin hole I on the metal matrix 1, the pin hole II on the composite material insert 2, and the pin hole III on the rubber ring 4. 1. High manganese steel of model ZGMn13Cr is used as the base material, the composite material insert 2 is ceramic / metal matrix composite material insert, and the rubber ring 4 has the functions of anti-slip and shock absorption.

[0040] Wherein the specific steps ...

Embodiment 3

[0046] A new type of wear-resistant composite material fan coal mill strike plate, including a metal base 1, a composite material insert 2, a pin 3, and a rubber ring 4, the metal base is evenly opened with through holes and pin holes I, and the composite material insert 2 One end protrudes, the other end is a stepped shaft, and one end of the stepped shaft is covered with a rubber ring 4, and the composite material insert 2 has a pin hole II, and the rubber ring 4 has a pin hole III, and the composite material insert 2 is embedded in the metal matrix 1 Above, the pin 3 passes through the pin hole I on the metal matrix 1, the pin hole II on the composite material insert 2, and the pin hole III on the rubber ring 4. 1. High manganese steel of model ZGMn13Cr is used as the base material, the composite material insert 2 is ceramic / metal matrix composite material insert, and the rubber ring 4 has the functions of anti-slip and shock absorption.

[0047] Wherein the specific steps ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com