Tire mold and manufacturing method thereof

A tire mold and manufacturing method technology, applied to tires, household appliances, other household appliances, etc., can solve the problems of surface damage of blocks, affecting the appearance performance of tires, uneven distribution of tire patterns, etc., to prevent loosening, high inlaying efficiency, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

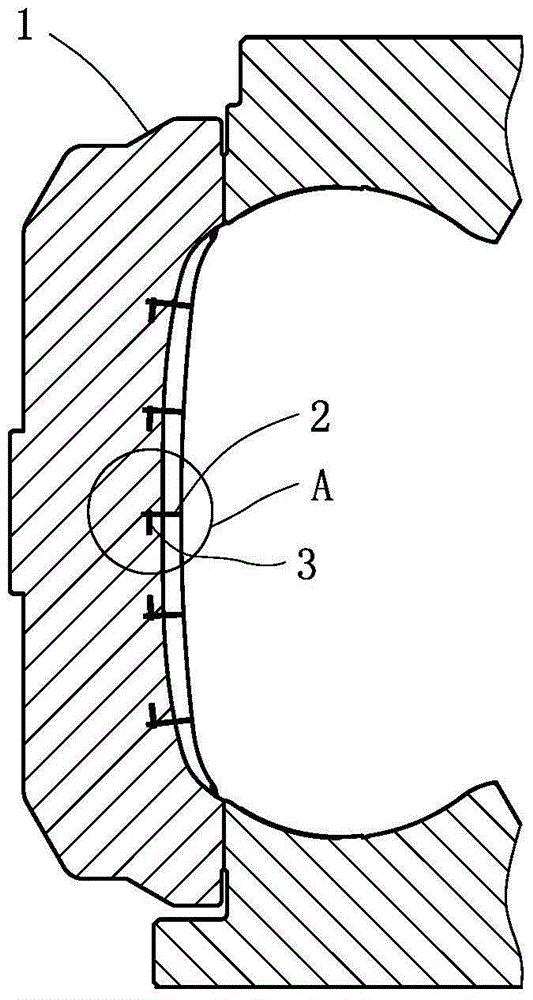

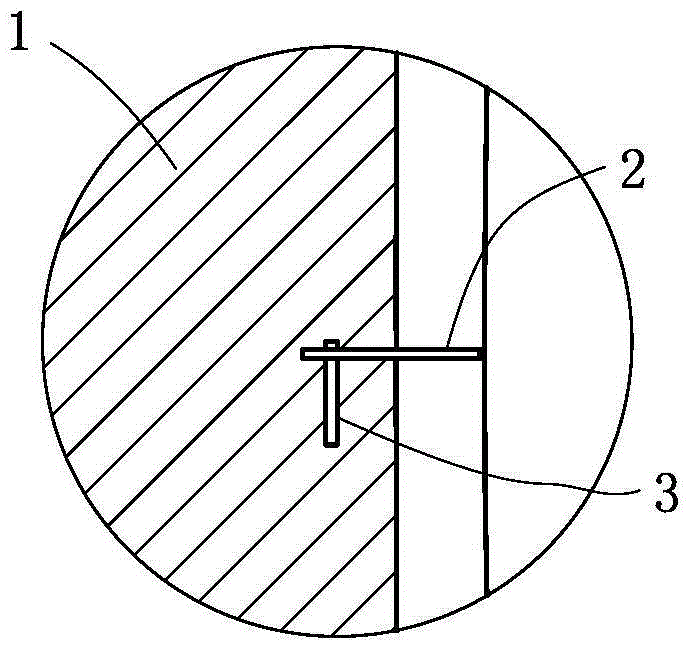

[0036] Such as figure 1 , figure 2 with image 3 Commonly shown, the present invention provides a tire mold, comprising a mold body 1, a plurality of steel sheets 2 are arranged on the mold body 1, and a plurality of mounting holes 201 penetrating through the steel sheets 2 are provided on the steel sheet 2, and the mounting holes 201 can be designed One row, and multiple rows can also be designed. Those skilled in the art can set it by themselves according to the needs, and there is no limitation here. A pin 3 is inserted in the mounting hole 201. The extension direction of the pin 3 is perpendicular to the surface of the steel sheet 2. The pin 3 is embedded Installed in the mold body 1.

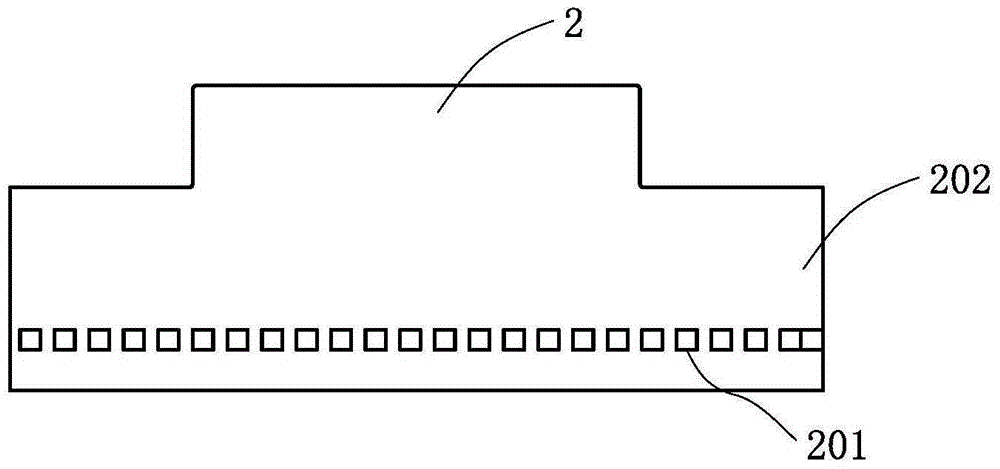

[0037] Such as Figure 4 with Figure 5 As shown together, the shape of the pin 3 is a U-shaped structure, and the two nail legs 301 of the pin 3 are inserted into the installation hole 201. The two nail legs 301 can have the same thickness or different thicknesses, and can be of the s...

Embodiment 2

[0039] Such as Image 6 with Figure 7 Commonly shown, the present invention provides a tire mold, its structure is basically the same as that of Embodiment 1, the difference is that the shape of the pin 3 is a columnar structure, and the pin 3 is provided with a nail cap 303 for limiting the position of the pin 3, and the pin The shape of the cap 303 can be various shapes such as hemispherical, round cake shape, square, bar shape, triangle, etc., the cross-sectional area of the nail cap 303 is greater than the cross-sectional area of the mounting hole 201, and the nail cap 303 can be positioned at the end of the pin 3, or It can be located in the middle of the pin 3. Of course, from the analysis of the stress situation, when the nail cap 303 is set in the middle of the pin 3, the force on both sides of the pin 3 will be more uniform, the fixation will be more firm, and it will be less likely to be on the surface of the mold body 1. Looseness occurs.

[0040] The pin 3 a...

Embodiment 3

[0042] Such as Figure 1 to Figure 7Commonly shown, the invention provides a kind of manufacturing method of tire mold, comprises the following steps:

[0043] (1) process the base mold of mold body 1, insert steel sheet 2 on the steel sheet slot reserved on the base mold, and adjust the depth position of steel sheet 2 on the base mold simultaneously;

[0044] (2) Utilize the base mold to make a rubber mold, insert the steel sheet 2 with the installation hole 201 into the corresponding steel sheet groove on the rubber mold, and then reverse it into a plaster mold, the steel sheet with the installation hole 201 The base body 202 will expose the plaster mold;

[0045] (3) Insert the pin 3 into the mounting hole 201;

[0046] (4) The pin 3 is fixedly connected to the steel sheet 2;

[0047] (5) cast the tire mold with the gypsum mold inlaid with the steel sheet 2, remove the gypsum after casting, and the steel sheet matrix 202 is embedded in the inside of the mold body 1;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com