Polysiloxane/titanium sol photocatalytic composite film and preparation method thereof

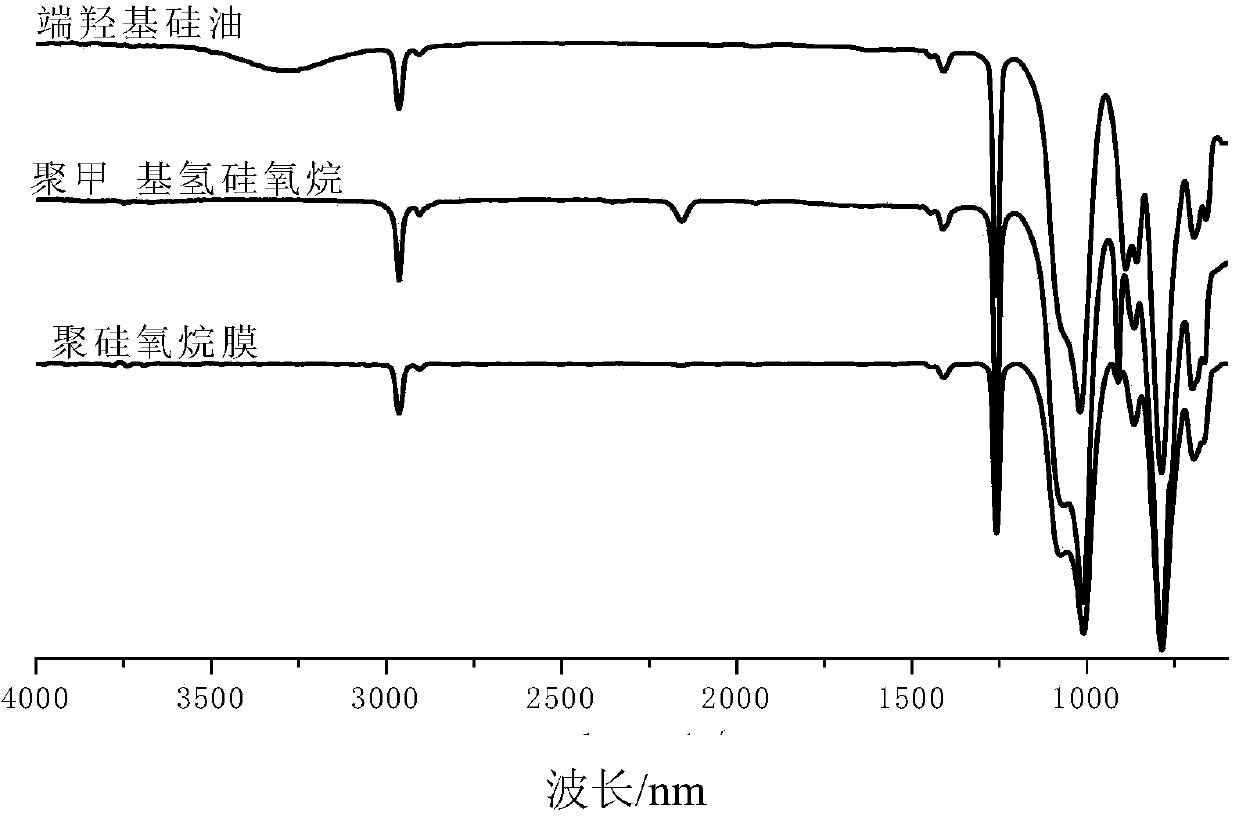

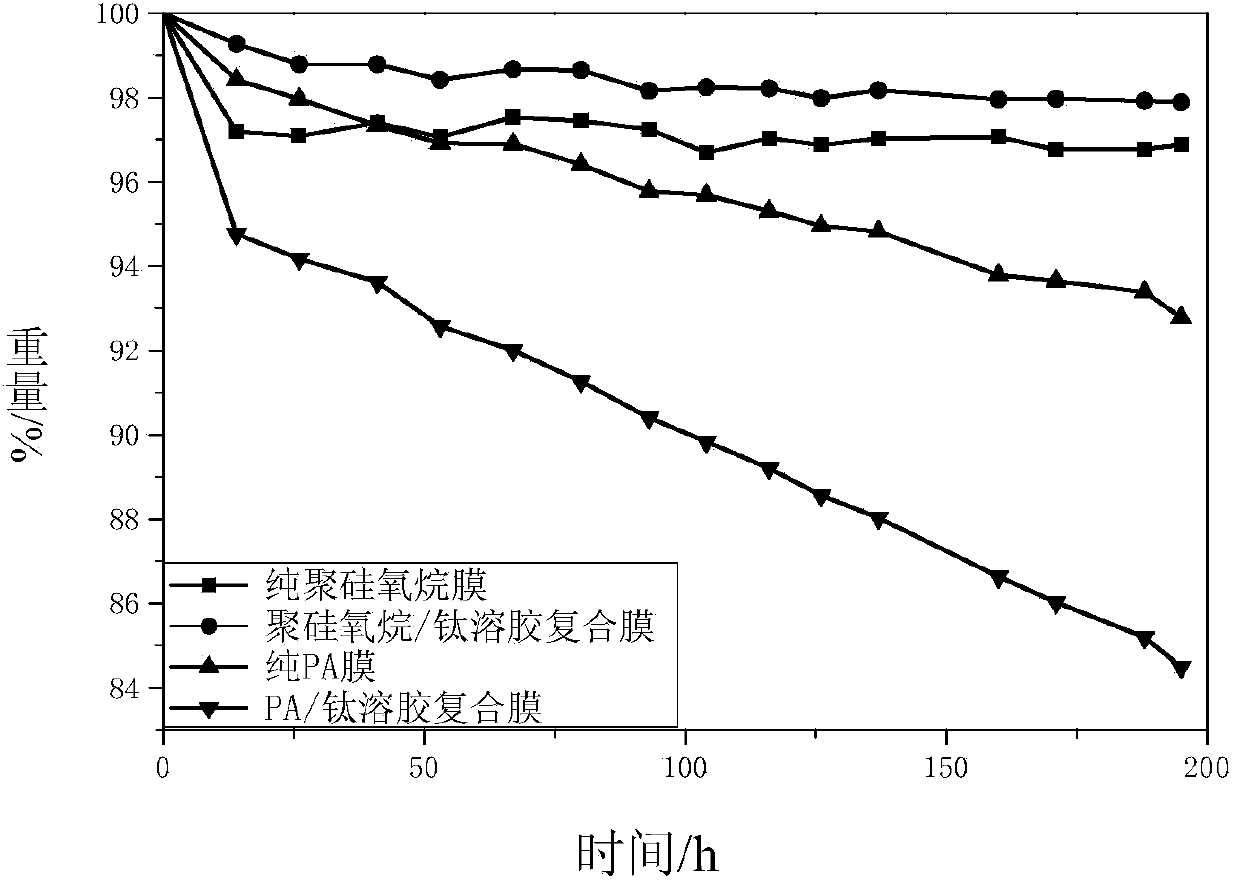

A technology of polysiloxane and polymethylhydrogensiloxane, which is applied in the field of polysiloxane/titanium sol photocatalytic composite film and its preparation, can solve the problems of poor photocatalysis and ultraviolet shielding ability, coating mechanics, optical , photocatalytic and aging resistance and other poor performance problems, to achieve excellent photocatalytic performance, easy to implement, and good anti-ultraviolet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

[0047] Put a certain amount of hydroxy-terminated silicone oil, polymethylhydrogensiloxane, and titanium sol (wherein, toluene is 100g) into a beaker and stir, then add a small amount of film-forming solvent toluene (28g), totaling 128g of toluene in the system, mix After uniformity (the total weight of hydroxyl-terminated silicone oil and polymethylhydrogensiloxane is 100g, which is used as the basis for the quality of other materials added), Karstedt platinum catalyst is added dropwise to initiate the condensation reaction between silicone oils, and poured into polytetrafluoroethylene in the mold. Under the environment of 80°C, with the volatilization of the solvent and the gradual progress of the condensation reaction, the three-dimensional crosslinked structure is constructed and the film is further formed. After 24 hours, the titanium sol particles are uniformly dispersed and partially embedded on the surface of the polysiloxane matrix. The permanent composite film, that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com