Preparation method for zinc arsenide

A technology for diarsenic trizinc and zinc ingots, applied in chemical instruments and methods, arsenic compounds, inorganic chemistry, etc., can solve the problems of small synthesis scale, complicated process, slow reaction speed, etc., and the synthesis scale can be large or small. , The reaction conditions are easy to control, and the reaction is completely and fully effected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

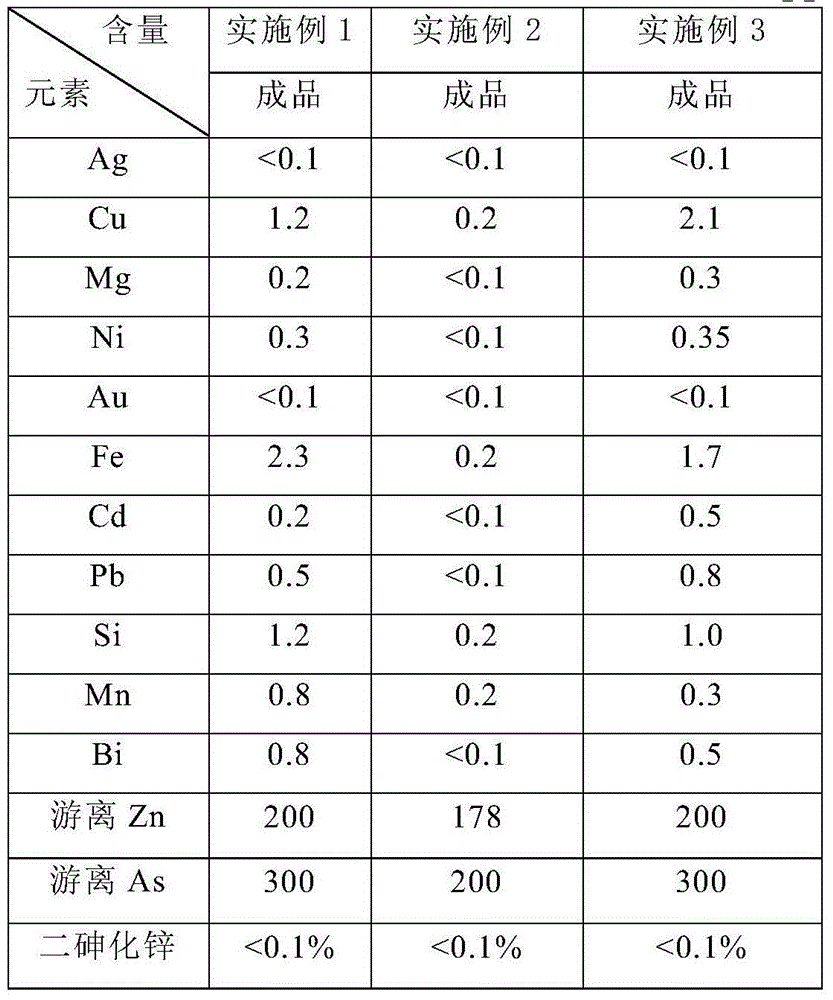

Examples

preparation example Construction

[0010] Firstly, the preparation method of zinc diarsenide according to the present invention is described, including steps: (1) weighing high-purity arsenic particles and high-purity zinc ingots according to the molar ratio of arsenic and zinc in zinc diarsenide, Evenly spread the weighed high-purity arsenic particles in a crucible boat, then cover the high-purity zinc ingots on the high-purity arsenic particles, and then put the crucible boat horizontally into the flat-mouthed quartz tube; A flat quartz tube with high purity arsenic pellets and high purity zinc ingots is evacuated to 10 -2 Below Pa, then use a hydrogen-oxygen flame to seal the flat-mouthed quartz tube at high temperature; (3) Put the sealed flat-mouthed quartz tube into the horizontal synthesis furnace, and raise the temperature to 470-550 °C at a heating rate of 8-15 °C / min And keep it warm for 90-150min, then raise the temperature to 780-850℃ at a heating rate of 5-7℃ / min and keep it warm for 60-120min, the...

Embodiment 1

[0024] (1) Put a 30cm-long high-purity graphite crucible boat filled with 5N high-purity zinc in the quartz tube of the grinding head and pass nitrogen protection into the quartz tube of the grinding head, then put the quartz tube of the grinding head into the horizontal heating furnace horizontally, and then The temperature of the horizontal heating furnace is raised to 455°C, and the temperature is kept constant for 60 minutes. After the high-purity zinc is completely melted, the horizontal heating furnace is turned off so that the high-purity zinc in the high-purity graphite crucible boat is cooled to room temperature with the furnace to form a high-purity zinc ingot;

[0025] (2) Open the quartz tube of the grinding head to take out the high-purity zinc ingot, soak in dilute hydrochloric acid for 2 minutes to treat the oxide film on the surface, then rinse it with deionized water and dry it in vacuum. The weight of the treated high-purity zinc ingot is 453.6 g;

[0026] (3...

Embodiment 2

[0031] (1) Put a 45cm-long high-purity zirconia crucible boat filled with 6N high-purity zinc in the quartz tube of the grinding head and pass argon gas into the quartz tube of the grinding head for protection, and then put the quartz tube of the grinding head into the horizontal heating furnace horizontally Afterwards, the temperature of the horizontal heating furnace is raised to 500 ° C, and the temperature is kept constant for 40 minutes. After the high-purity zinc is completely melted, the horizontal heating furnace is closed to cool the high-purity zinc to room temperature in the high-purity zirconia crucible boat to form a high-purity zinc ingot;

[0032] (2) Open the quartz tube of the grinding head to take out the high-purity zinc ingot, soak it in dilute hydrochloric acid for 3 minutes to treat the oxide film on the surface, then rinse it with deionized water and dry it in vacuum. The weight of the treated high-purity zinc ingot is 921.1 g;

[0033] (3) Calculate and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com