Supported hydrosilylation catalyst and preparation method thereof

A technology for hydrosilylation reaction and catalyst, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc. Low selectivity, catalyst deactivation and other problems, to achieve the effect of easy control, high catalytic activity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

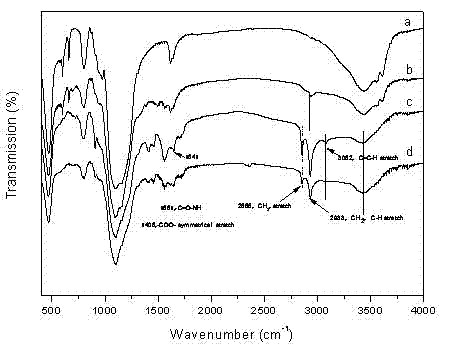

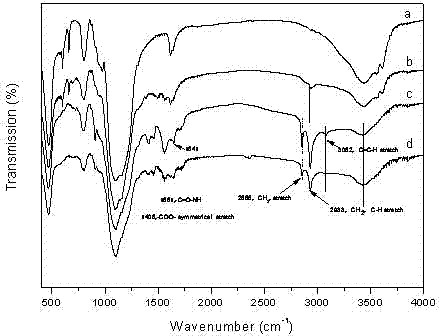

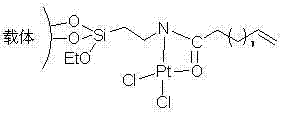

Method used

Image

Examples

Embodiment 1

[0021] 1) Modify the surface of the carrier with a coupling agent: In a 500 mL reactor with a feeding port and a stirring device, add 20.0 g of silica gel and 250 mL of toluene, stir at room temperature for 10 min, add 10.0 g of γ-aminopropyltriethyl Oxysilane, stirred for 20 min, added dropwise a mixed solution of 10 mL of water and 30 mL of ethanol at room temperature, stirred for 2 h, heated to reflux at 100 °C and stirred for 2 h. Toluene and ethanol were removed to obtain a white powder, which was dried under vacuum at 80 °C for 24 h to obtain primary modified silica.

[0022] 2) Modify the surface of the carrier with a functional group compound: In a 250 mL three-necked flask, add 2.0 g of the functional group compound undecylenic acid and 100 mL of water, heat up to 80 °C, stir to completely dissolve the undecylenic acid, add 6.0 g of the undecylenic acid in step 1 ) primary modified silica, keep the temperature and continue to stir for 3 h, filter and wash to obtain a ...

Embodiment 2

[0025] 1) Modify the surface of the support with a coupling agent: In a 500 mL reactor with a feeding port and a stirring device, add 20.0 g of silica gel and 250 mL of toluene, stir at room temperature for 10 min, add 6.0 g of γ-aminopropyl tris Ethoxysilane, stirred for 20 min, added dropwise a mixed solution of 10 mL of water and 30 mL of ethanol at room temperature, stirred for 2 h, heated to reflux at 100 °C and stirred for 2 h. Toluene and ethanol were removed to obtain a white powder, which was dried under vacuum at 80 °C for 24 h to obtain a modified carrier.

[0026] 2) Modify the surface of the carrier with functional groups: In a 250mL three-necked flask, add 2.0 g of undecylenic acid and 100 mL of water, heat up to 80°C, stir to completely dissolve the undecylenic acid, and add 6.0 g of the product obtained in step 1) , keep the temperature and continue to stir for 3 h, filter and wash to obtain a light yellow powder, which is dried at 80 °C for 24 h under vacuum t...

Embodiment 3

[0029] 1) Modify the surface of the carrier with a coupling agent: In a 500 mL reactor with a feeding port and a stirring device, add 20.0 g of silica gel and 250 mL of toluene, stir at room temperature for 10 min, add 5.0 g of γ-aminopropyl trimethyl Oxysilane, stirred for 20 min, added dropwise a mixed solution of 10 mL of water and 30 mL of ethanol at room temperature, stirred for 2 h, heated to reflux at 100 °C and stirred for 2 h. Toluene and ethanol were removed to obtain a white powder, which was dried under vacuum at 80 °C for 24 h to obtain a modified carrier.

[0030] 2) Modify the surface of the carrier with functional groups: In a 250mL three-necked flask, add 2.0 g of undecylenic acid and 100 mL of water, heat up to 80°C, stir to completely dissolve the undecylenic acid, and add 6.0 g of the product obtained in step 1) , keep the temperature and continue to stir for 3 h, filter and wash to obtain a light yellow powder, which is dried at 80 °C for 24 h under vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com