Preparation method of vanillin glucoside and application of vanillin glucoside in tobacco flavoring

A technology of glucoside and vanillin, which is applied in the field of tobacco aroma enhancement, can solve the problems of application limitations, and achieve the effects of improving aroma richness, wide application prospects, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

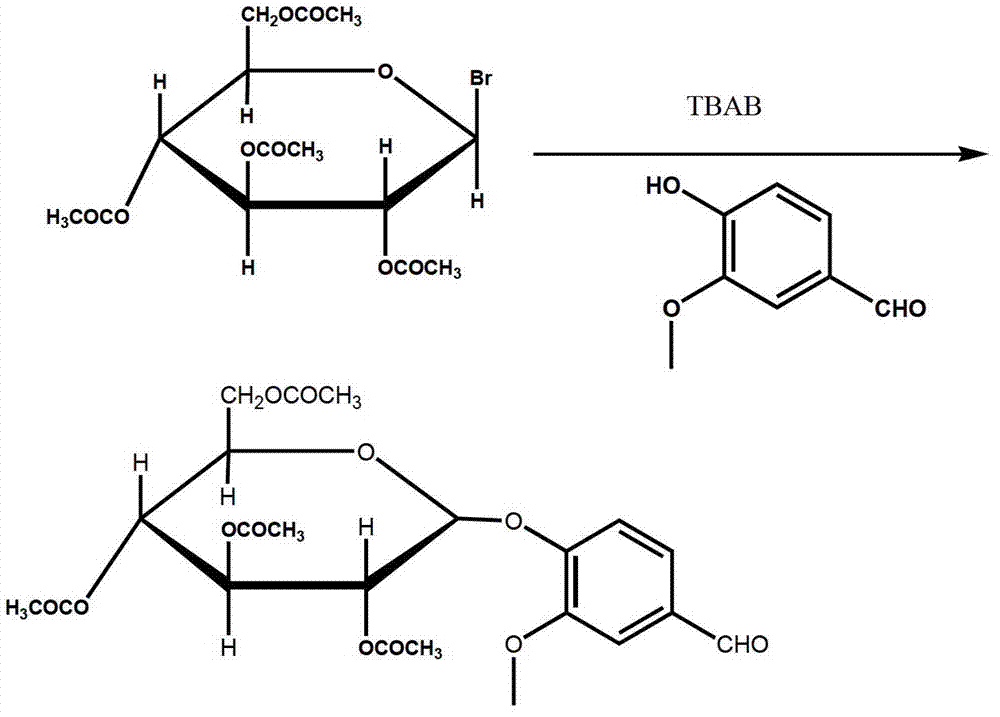

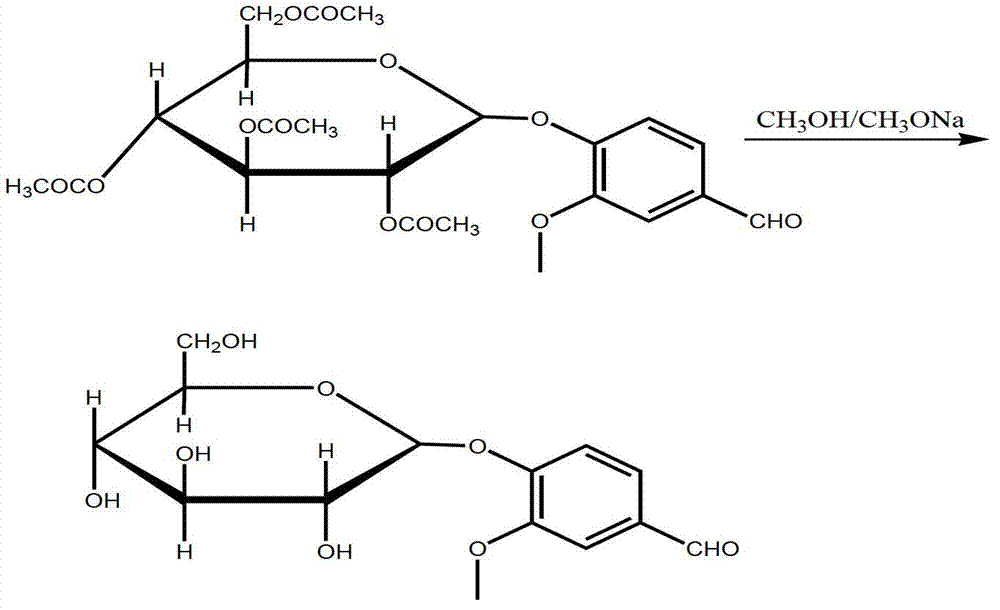

[0029] Step 1, the synthesis of tetraacetylglucose vanillin

[0030]Add chloroform to dissolve 100g tetraacetylbromoglucose in a triangular flask, transfer it into a constant pressure dropping funnel after completely dissolving; weigh 20g of vanillin and add it to potassium carbonate solution, make it completely dissolved, and then transfer it into another constant pressure funnel. In the dropping funnel; add 7g of tetrabutylammonium bromide to a four-necked flask equipped with a reflux condenser, a thermometer and a constant pressure dropping funnel, then add 50ml of water and 50ml of chloroform, heat to an external temperature of 45°C and stir Make it dissolve; while stirring, add dropwise the tetraacetylbromoglucose solution dissolved in chloroform and the vanillin solution of sodium bicarbonate, and keep the external temperature at 45°C during the dropwise addition; then heat and stir for 6 hours; after the reaction Cool to room temperature, add 70ml of chloroform and 100m...

Embodiment 2

[0034] Step 1, the synthesis of tetraacetylglucose vanillin

[0035] Add chloroform to dissolve 50g of tetraacetylbromoglucose in a triangular flask, transfer it into a constant pressure dropping funnel after completely dissolving; weigh 10g of vanillin and add it to potassium carbonate solution, make it completely dissolved, and then transfer it into another constant pressure funnel. In the dropping funnel; add 4g of tetrabutylammonium bromide to a four-necked flask equipped with a reflux condenser, a thermometer and a constant pressure dropping funnel, then add 40ml of water and 40ml of chloroform, heat to an external temperature of 50°C and stir Make it dissolve; while stirring, add dropwise the tetraacetylbromoglucose solution dissolved in chloroform and the vanillin solution of sodium bicarbonate, and keep the external temperature at 50°C during the dropwise addition; then heat and stir for 5 hours; cool down after the reaction to room temperature, add 50ml of chloroform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com