Method for preparing 3-hydroxy butyrate

A technology of hydroxybutyrate and hydroxybutyrate, applied in the field of preparation of 3-hydroxybutyrate, can solve the problems of large production equipment requirements, high risk factor, long reaction time, etc. Simple and safe operation, the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of preparation method of 3-hydroxybutyrate sodium that the present invention proposes, comprises the following steps:

[0021] S1. Add 0.93g of aluminum-nickel alloy catalyst accounting for 0.7% of its weight to 132.8g of 98% ethyl acetoacetate, carry out acyl hydrogenation reaction at normal pressure and 40°C, the reaction time is 10h, and suction filter after the reaction is completed , 129.5 g of ethyl 3-hydroxybutyrate was obtained, and the yield was 98.0%;

[0022] S2. Dissolve 129.5 g of ethyl 3-hydroxybutyrate in 388.5 g of water, the ratio of solid to liquid is 1:3, and then add 39.6 g of 99% sodium hydroxide, among which, ethyl 3-hydroxybutyrate and sodium hydroxide The molar ratio was 1:1, and reacted at 10°C for 2 hours. After the reaction, activated carbon was added to decolorize, filtered, and the filtrate was concentrated, crystallized, and dried to obtain 122.7 g of sodium 3-hydroxybutyrate with a yield of 98.5%.

[0023] The purity of the prepare...

Embodiment 2

[0025] A kind of preparation method of 3-hydroxybutyrate potassium that the present invention proposes, comprises the following steps:

[0026] S1. Add 1.06g of aluminum-nickel alloy catalyst accounting for 0.8% of its weight to 132.8g of 98% ethyl acetoacetate, carry out acyl hydrogenation reaction at normal pressure and 60°C, the reaction time is 12h, and suction filter after the reaction is completed , 130.44 g of ethyl 3-hydroxybutyrate was obtained, and the yield was 98.7%;

[0027] S2. Dissolve 130.44 g of ethyl 3-hydroxybutyrate in 456.5 g of water, the ratio of solid to liquid is 1:3.5, and then add 58 g of potassium hydroxide, wherein the molar ratio of 3-hydroxybutyrate to potassium hydroxide is 1:1.05, reacted at 10°C for 4 hours, after the reaction was completed, activated carbon was added for decolorization, filtered, the filtrate was concentrated, crystallized, and dried to obtain 140.35 g of potassium 3-hydroxybutyrate with a yield of 99.0%.

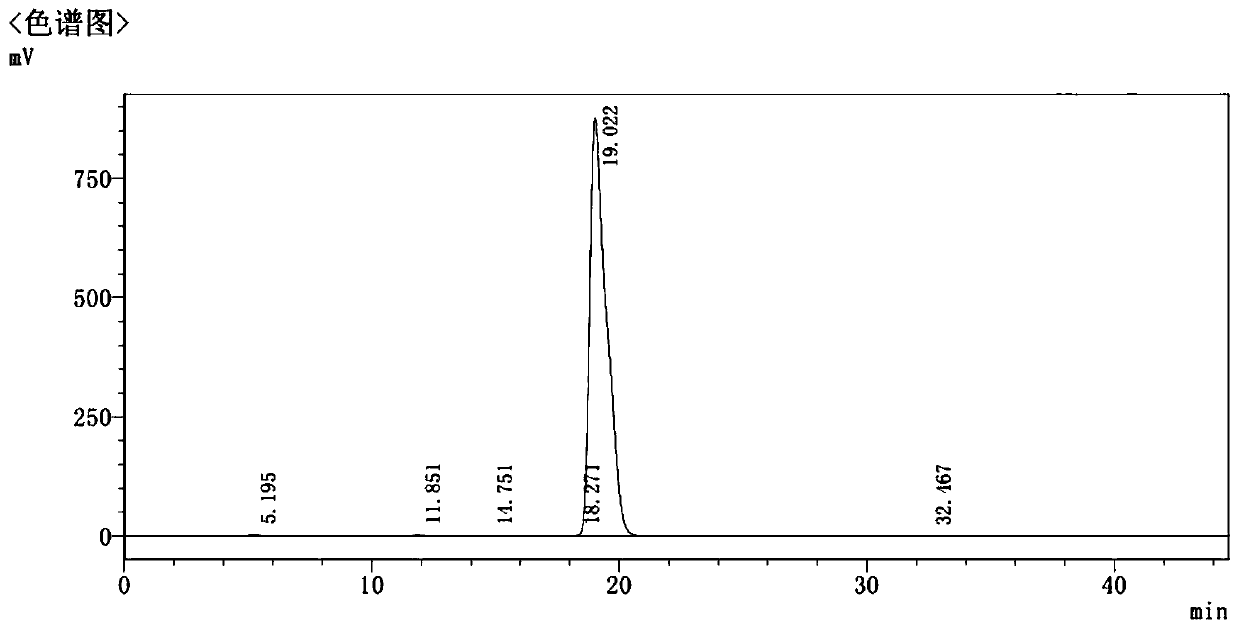

[0028] HPLC was u...

Embodiment 3

[0030] A kind of preparation method of 3-hydroxybutyrate calcium that the present invention proposes, comprises the following steps:

[0031] S1. Add 1.33g of aluminum-nickel alloy catalyst accounting for 1.0% of its weight to 132.8g of 98% ethyl acetoacetate, carry out acyl hydrogenation reaction at normal pressure and 80°C, the reaction time is 14h, and suction filter after the reaction is completed , 130.84 g of ethyl 3-hydroxybutyrate was obtained, and the yield was 99.0%;

[0032] S2. Dissolve 130.84g of ethyl 3-hydroxybutyrate in 523.4g of water, the ratio of solid to liquid is 1:4, and then add 40.3g of calcium hydroxide. Among them, the molar ratio of 3-hydroxybutyrate to calcium hydroxide 1:0.55, react at 15°C for 6h, after the reaction, add activated carbon to decolorize, filter, concentrate the filtrate, crystallize, dry to obtain 121.8g of calcium 3-hydroxybutyrate with a yield of 98.5%.

[0033] HPLC was used to detect the purity of the prepared calcium 3-hydroxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com