Preparation method for dextran with weight average molecular weight of 3000-6000Da

A technology of molecular dextran and ultra-micro-molecule dextran, which is applied in the field of fine chemicals, can solve the problems of long degradation time, high production cost, increased production cost, etc., and achieves the effects of mild reaction conditions, low production cost and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

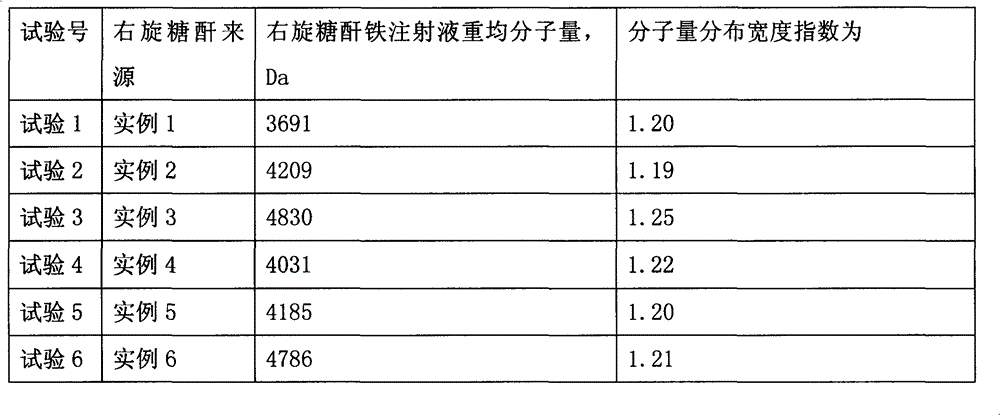

Examples

example 1

[0015] Add 18g of dextran with a weight-average molecular weight of 7000Da and 360ml of distilled water into a 500ml three-necked flask with agitator and water bath heating, start the agitator, raise the temperature to 35°C, adjust the pH of the solution to 3.5, add 720 units of dextranase, and react at constant temperature 5 minutes, then directly raise the temperature to 80°C, stir for 10 minutes, and inactivate the dextranase to obtain a ultra-micromolecular dextran solution. The high-pressure liquid chromatography shows a single narrow peak, the weight-average molecular weight is 3553Da, and the molecular weight distribution width index is 1.23.

[0016] The ultra-micromolecular dextran solution prepared by the above method can be directly used to produce ultra-micromolecular iron dextran injection without treatment.

example 2

[0018] Add 18g of dextran 40 (weight average molecular weight is 40000Da) and 55ml of distilled water in a 500ml three-necked flask heated by a stirrer and a water bath, start the stirrer, heat up to 50°C, the pH of the solution is 5.0, add 3250 units of dextranase, and react at a constant temperature 15 minutes, then directly raise the temperature to 90°C, stir for 10 minutes, and inactivate dextranase to obtain ultra-micromolecular dextran solution. The high-pressure liquid chromatography shows a single narrow peak, the weight-average molecular weight is 4560Da, and the molecular weight distribution width index is 1.21.

[0019] The ultra-micromolecular dextran solution prepared by the above method can be directly used to produce ultra-micromolecular iron dextran injection without treatment.

example 3

[0021] Add 50g dextran 70 (weight average molecular weight is 76000Da) and 50ml distilled water in the 500ml there-necked flask with stirrer and water bath heating, start stirrer, be warming up to 65 ℃, the solution pH is adjusted to 9.0, add 5000 units of dextranase, React at constant temperature for 40 minutes, then directly raise the temperature to 100°C, stir for 10 minutes, and inactivate dextranase to obtain ultra-micromolecular dextran solution. High-pressure liquid chromatography shows a single narrow peak with a weight-average molecular weight of 5020 Da and a wide molecular weight distribution. The index is 1.25.

[0022] The ultra-micromolecular dextran solution prepared by the above method can be directly used to produce ultra-micromolecular iron dextran injection without treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com