Preparation method of 2,2-difluoroethylamine

A technology of difluoroethylamine and difluoroethanol, which is applied in the preparation of organic compounds, preparation of amino compounds, chemical instruments and methods, etc., which can solve the difficulty of continuous production in kettle reactions, difficulty in recycling catalysts, and difficulties in industrial production, etc. problems, to achieve the effects of easy continuous production, high reaction conversion rate and yield, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In a single-tube reactor with a diameter of 20 mm, add 200 ml of alumina as a catalyst carrier, and under the conditions of a pressure of 0.5 MPa and a temperature of 180 ° C, and a hydrogen atmosphere, 2,2-difluoroethanol and liquid ammonia are introduced. The mixture, the molar ratio of 2,2-difluoroethanol to liquid ammonia is 1:5, and the liquid phase space velocity is 0.5h -1 , the residence time of 2,2-difluoroethanol was 44s, and the reaction yield was 82%.

[0031] Yield is defined as follows:

[0032] The mole percentage of the main raw material converted to the target product is used as the definition of the yield

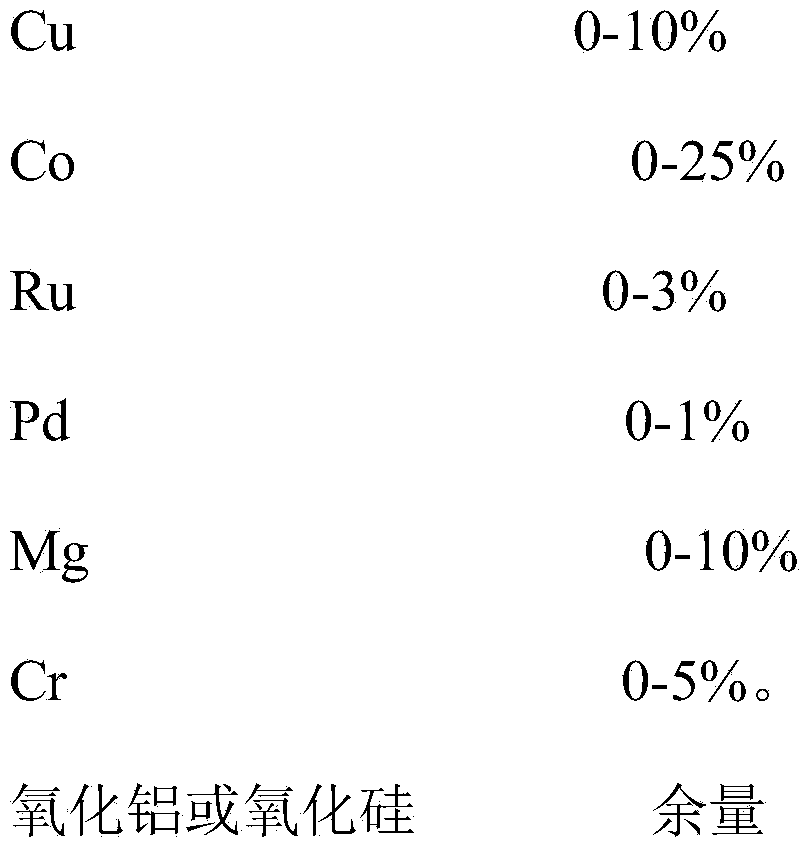

[0033] Described catalyst comprises the component of following percentage by weight:

[0034]

[0035] The preparation method is as follows:

[0036] Using commercially available aluminum hydroxide as raw material, use 40% sodium hydroxide solution to make sodium metaaluminate solution, neutralize the precipitate with nitric acid, age, wash, f...

Embodiment 2

[0039] In a single-tube reactor with a diameter of 20mm, add 200ml of silicon oxide as a catalyst carrier, and under the conditions of a pressure of 0.8Mpa and a temperature of 175°C, and a hydrogen atmosphere, 2,2-difluoroethanol and liquid ammonia are introduced. The mixture, the molar ratio of 2,2-difluoroethanol to liquid ammonia is 1:8, and the liquid phase space velocity is 0.6h -1 , the residence time of 2,2-difluoroethanol was 37s, and the reaction yield was 79%.

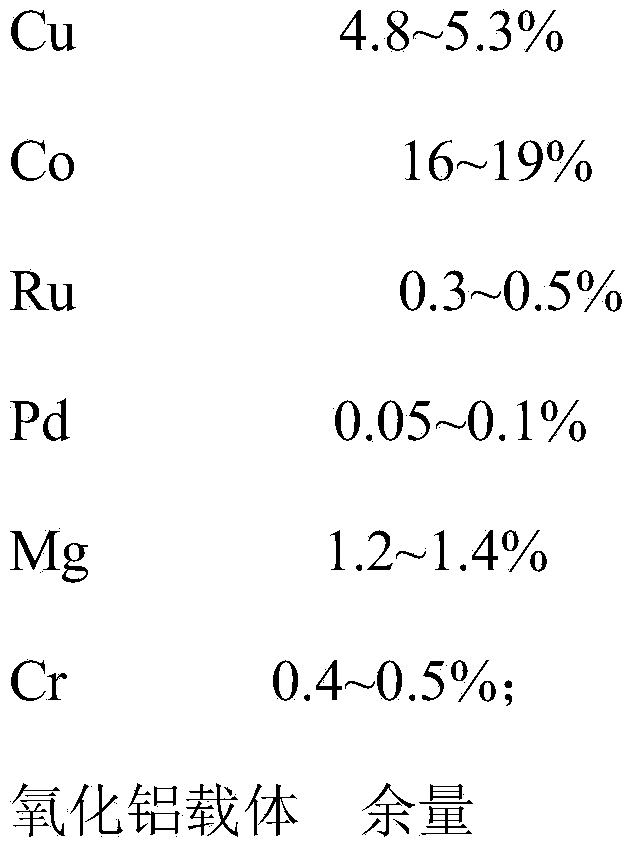

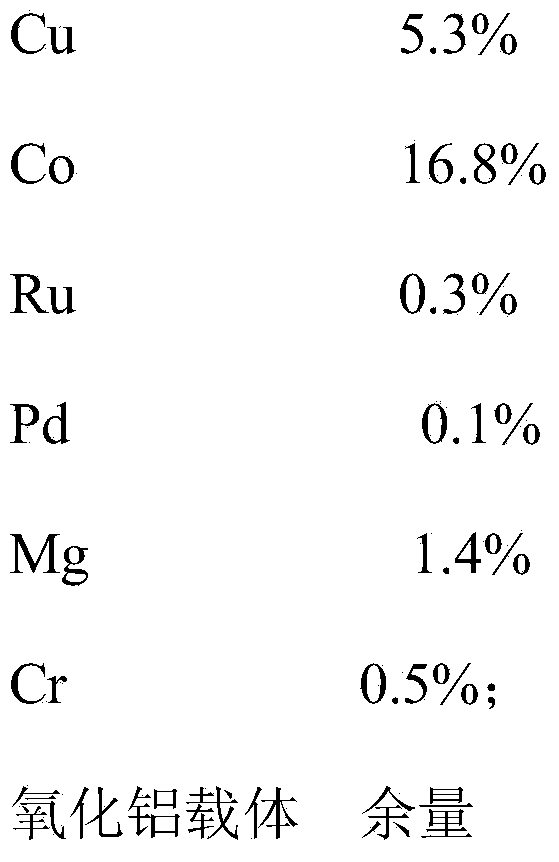

[0040] Described catalyst comprises the component of following percentage by weight:

[0041]

[0042] The preparation method is the same as that in Example 1, and the carrier adopts commercially available silicon oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com