MgO partially stabilized ZrO, MgO partially stabilized ZrO ceramic, preparation methods of MgO partially stabilized ZrO and MgO partially stabilized ZrO ceramic and application of MgO partially stabilized ZrO ceramic

A technology for stabilizing zirconia and magnesia, applied in the field of magnesia partially stabilized zirconia ceramics and their preparation, and magnesia partially stabilized zirconia field, which can solve the problem that mechanical mixing method is difficult to disperse uniformly, stabilized zirconia has low sintering activity and grain size. growing up etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

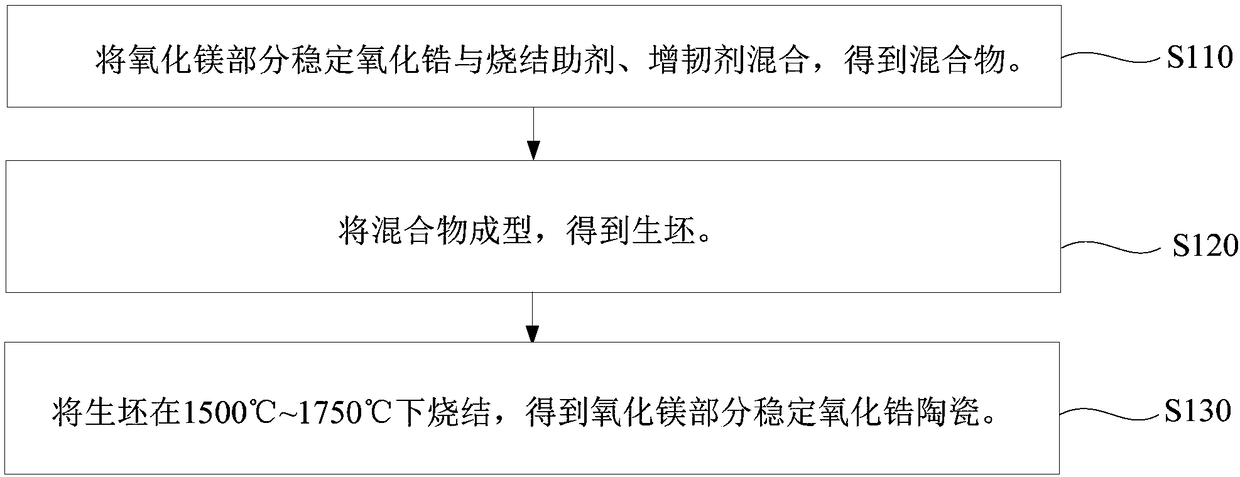

[0027] Such as figure 1 As shown, a method for preparing magnesia partially stabilized zirconia ceramics in one embodiment comprises the following steps:

[0028] S110: Mixing magnesia partially stabilized zirconia with sintering aid and toughening agent to obtain a mixture.

[0029] In one embodiment, step S110 includes: ball milling and mixing magnesia partially stabilized zirconia, sintering aid, toughening agent and solvent to obtain a mixed slurry, and then granulating the mixed slurry to obtain a mixture. Specifically, the mass ratio of the sum of the mass of magnesia partially stabilized zirconia, sintering aid and toughening agent to the grinding medium and solvent is 1:2:1; the ball milling time is 12 hours to 24 hours; the mixed slurry The granulation method is spray granulation.

[0030] In one of the embodiments, the step of spray granulation includes: mixing the mixed slurry with binder, dispersant, defoamer and water ball mill to form spray slurry, wherein, in ...

Embodiment 1-1

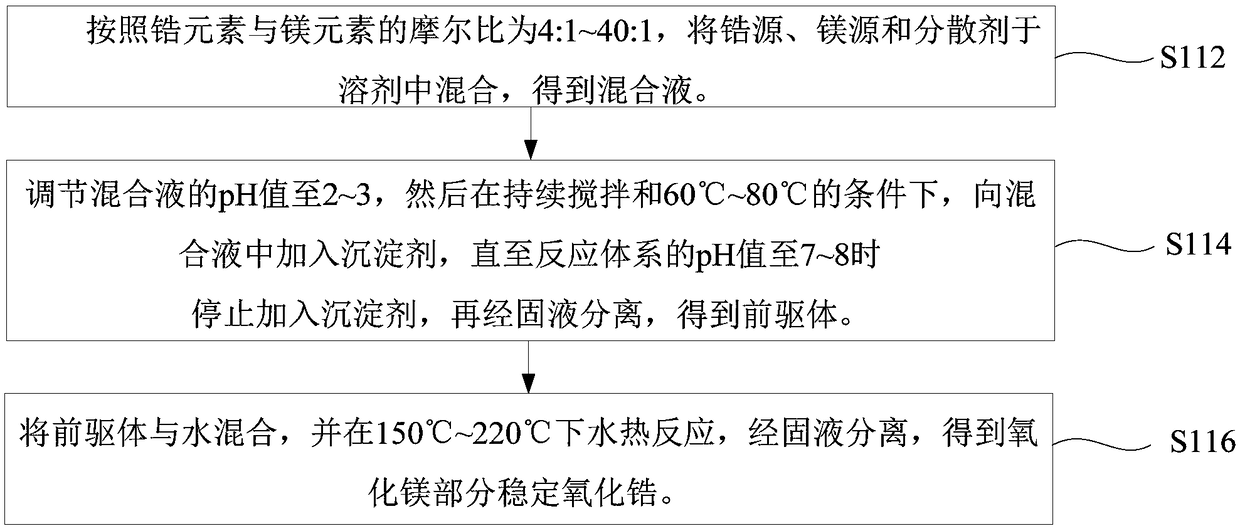

[0061] The preparation process of the magnesium oxide partially stabilized zirconia of the present embodiment is as follows:

[0062] (1) according to the mol ratio of zirconium element and magnesium element is 10:1, zirconium oxychloride is dissolved in the mixed solution that mass ratio is 1:1.5 water and ethanol, then adds magnesium chloride hexahydrate under the condition of stirring, obtains Premixed liquid, and the molar concentration of zirconium element in the premixed liquid is 1.5mol / L, the molar concentration of magnesium element is 0.15mol / L, then add glycerol, the mass ratio of glycerol and premixed liquid is 0.5:100, obtain Mixture.

[0063] (2) Adjust the pH value of the mixed solution to 3 with ammonia water with a molar concentration of 5 mol / L, then add propylene oxide dropwise to the mixed solution under continuous stirring and 70°C, and the solution in the reaction system starts from transparent The solution turns into a milky white solution, then produces...

Embodiment 1-2

[0066] The preparation process of the magnesium oxide partially stabilized zirconia of the present embodiment is as follows:

[0067] (1) according to the mol ratio of zirconium element and magnesium element is 20:1, zirconium oxychloride is dissolved in the mixed solution that mass ratio is 1:1 water and ethanol, then add magnesium chloride hexahydrate under the condition of stirring, obtain Premix solution, and the molar concentration of zirconium element in the premix solution is 1mol / L, the molar concentration of magnesium element is 0.05mol / L, then add PEG400, the mass ratio of PEG400 and premix solution is 0.1:100, to obtain the mixed solution.

[0068](2) Use ammonia water with a molar concentration of 1mol / L to adjust the pH value of the mixed solution to 2, then add propylene oxide dropwise to the mixed solution under continuous stirring and 60°C, the solution in the reaction system starts from transparent The solution turns into a milky white solution, then produces ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com