Transition element doped barium-strontium titanate based composite ceramic and preparation method thereof

A technology of element doping and barium strontium titanate, which is applied in the field of strontium barium titanate-based composite ceramics and its preparation, can solve the problems of high microwave dielectric loss and reduced voltage control adjustability, so as to improve sintering performance and reduce Effect of Dielectric Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

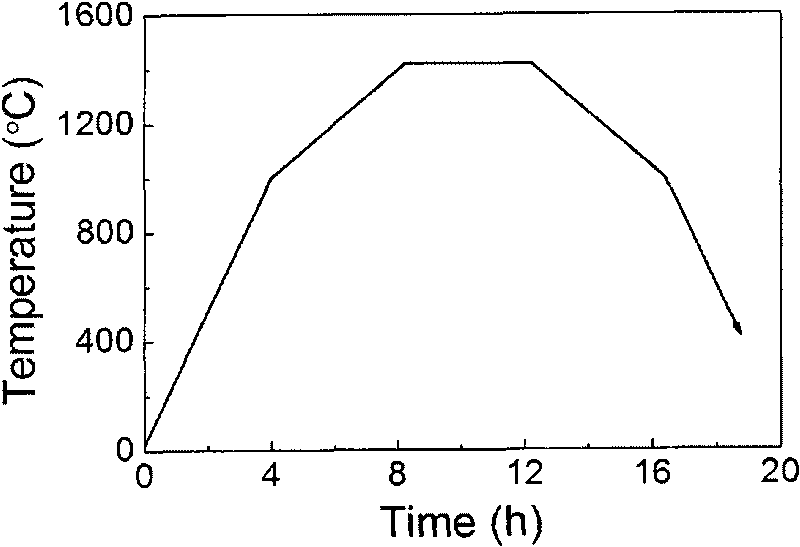

[0045] Press Ba 0.6 Sr 0.4 TiO 3 (BST) stoichiometric dose ratio Weigh an appropriate amount of BaCO 3 , SrCO 3 and TiO 2 Put the powder (purity ≥ 99.5%) into the agate mixing tank, add agate balls and alcohol, and mix on a three-roll mixer for 24 hours. The volume ratio of the agate balls, alcohol and powder is 6:2:1. The above mixed slurry was dried in an oven at 100°C, and then pre-fired in air at 1100°C×4h at normal pressure to obtain Ba 0.6 Sr 0.4 TiO 3 Powder.

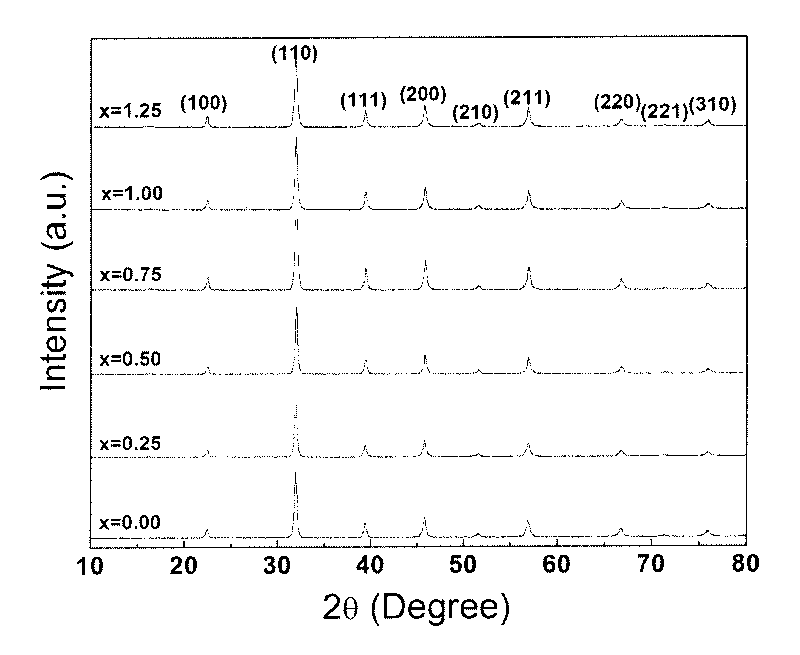

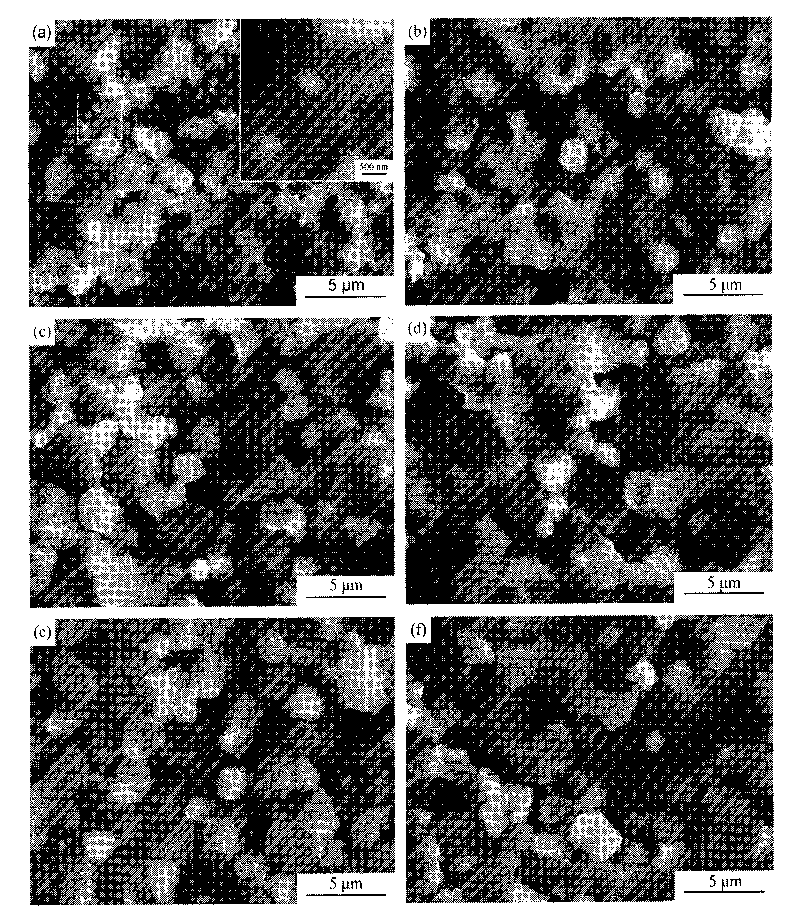

[0046] According to the above mixing process, the MnO 2 Powder (particle size 0.3~0.5μm, purity ≥99%) and Ba 0.6 Sr 0.4 TiO 3 Powder mixed evenly, MnO 2 with Ba 0.6 Sr 0.4 TiO 3 The molar ratio of the powder is 0.0%, 0.25%, 0.50%, 0.75%, 1.00% and 1.25%, respectively. The mixed powder was dried, and then pre-fired in air at 1100°C×4h to prepare Mn-doped Ba 0.6 Sr 0.4 TiO 3 Powder (Mn-Ba 0.6 Sr 0.4 TiO 3 ), the XRD analysis results of the powder are as follows figure 2 shown. It can be see...

Embodiment 2

[0051] Press Ba 0.6 Sr 0.4 TiO 3 Stoichiometric Dose Ratio Weigh an appropriate amount of BaCO 3 , SrCO 3 and TiO 2 (Purity≥99.5%) into the agate mixing tank, add agate balls and alcohol, mix on a three-roll mixer for 24h, the volume ratio of agate balls, alcohol and powder is 6:2:l. The above mixed slurry was dried in an oven at 100°C, and then pre-fired in air at 1100°C×4h at normal pressure to obtain Ba 0.6 Sr 0.4 TiO 3 Powder. According to the above mixing process, Fe 2 o 3 Powder (particle size 0.3~0.5μm, purity ≥99%) and Ba 0.6 Sr 0.4 TiO 3 Powder mixed evenly, Fe 2 o 3 Middle Fe and Ba 0.6 Sr 0.4 TiO 3 The molar ratio of the powder is 0.0%, 0.25%, 0.50%, 0.75%, 1.00% and 1.25%, respectively. The mixed powder was dried, and then pre-fired in air at 1100°C×4h to obtain Fe-doped Ba 0.6 Sr 0.4 TiO 3 Powder (Fe-Ba 0.6 Sr 0.4 TiO 3 ), the XRD analysis results of the powder are as follows Figure 4 shown. It can be seen that all Fe-BST powders form a ...

Embodiment 3

[0055] Press Ba 0.6 Sr 0.4 TiO 3 Stoichiometric Dose Ratio Weigh an appropriate amount of BaCO 3 , SrCO 3 and TiO 2 (purity ≥ 99.5%) into the agate mixing tank, add agate balls and alcohol, and mix on a three-roll mixer for 24 hours, the volume ratio of agate balls, alcohol and powder is 6:2:1. The above mixed slurry was dried in an oven at 100°C, and then pre-fired in air at 1100°C×4h at normal pressure to obtain Ba 0.6 Sr 0.4 TiO 3 Powder. According to the above mixing process, Co 2 o 3 Powder (particle size 0.3~0.5μm, purity ≥99%) and Ba 0.6 Sr 0.4 TiO 3 The powder is mixed evenly, Co 2 o 3 In Co and Ba 0.6 Sr 0.4 TiO 3 The molar ratio of the powder is 0.0%, 0.25%, 0.50%, 0.75%, 1.00% and 1.25%, respectively. The mixed powder was dried, and then pre-fired in air at 1100°C×4h to prepare Co-doped Ba 0.6 Sr 0.4 TiO 3 Powder (Co-Ba 0.6 Sr 0.4 TiO 3 ), the XRD analysis results of the powder are as follows Image 6 shown. It can be seen that all Co-BST p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com