A method for preparing nano-copper ferrite composite oxygen carrier by microwave hydrothermal method

A microwave hydrothermal method and nano-iron technology, applied in the direction of nanotechnology, nanotechnology, iron compounds, etc., can solve the problems of easy agglomeration, uneven particles, poor reaction performance, etc., and achieve short reaction time and complete grain development , the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 2.42gCu(NO 3 ) 2 ·3H 2 O and 8.08gFe(NO 3 ) 3 9H 2 O was dissolved in 200ml deionized water, ultrasonicated for 45min, and mixed evenly;

[0025] Add excess ammonia solution dropwise in the solution until the pH of the solution is 10, so that the precipitation is complete. Continue ultrasound for 60 minutes;

[0026] The precipitate was separated with a centrifuge and washed with deionized water until neutral;

[0027] Put the precipitate into the reaction kettle, add 1ml of dodecyltrimethylammonium bromide (DTAB) surfactant for modification, then add 200ml of deionized water, and place the reaction kettle in a microwave oven with a water-cooled reflux device Heating, holding at 180°C for 10 hours, separating the solid product after heating; washing and drying after natural cooling to obtain nano-copper ferrite.

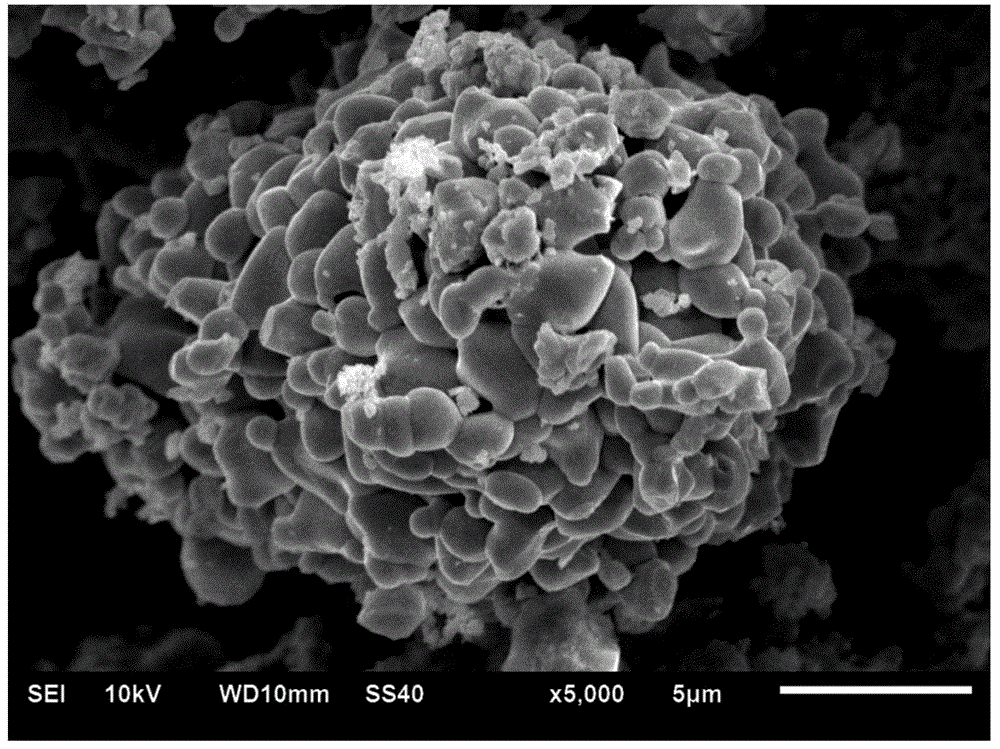

[0028] With the nano-copper ferrite prepared above as an oxygen carrier, such as figure 1 mentioned.

[0029] The oxygen carrier particles prep...

Embodiment 2

[0031] Take 2.42gCu(NO 3 ) 2 ·3H 2 O and 8.08gFe(NO 3 ) 3 9H 2 O was dissolved in 200ml deionized water, ultrasonicated for 60min, and mixed evenly;

[0032] Add excess ammonia solution dropwise in the solution until the pH of the solution is 11 to make the precipitation complete. Continue ultrasound for 70min;

[0033] Separate the precipitate with a centrifuge and wash with deionized water until neutral;

[0034] Put the precipitate into the reaction kettle, add 1ml of polyethylene glycol (PEG), and then add 200ml of deionized water, place the reaction kettle in a microwave oven with a water-cooled reflux device and heat it at 200°C for 10h. After the heating is completed Separating the solid product; washing and drying after natural cooling to obtain the nano-copper ferrite oxygen carrier.

[0035] The oxygen carrier particles prepared above were sieved, and 0.2 g of the oxygen carrier with a particle size of 100-150 mesh was taken for performance testing in a small...

Embodiment 3

[0037] Take 2.42gCu(NO 3 ) 2 ·3H 2 O and 8.08gFe(NO 3 ) 3 9H 2 O was dissolved in 200ml deionized water, ultrasonicated for 90min, and mixed evenly;

[0038] Add excess ammonia solution dropwise to the solution until the pH of the solution is 12 to complete the precipitation. Continue ultrasound for 90 minutes;

[0039] Separate the precipitate with a centrifuge and wash with deionized water until neutral;

[0040] Put the precipitate into the reactor, add 1ml of polyethylene glycol (PEG), then add 250ml of deionized water, heat the reactor in a microwave oven with a water-cooled reflux device, keep it at 220°C for 20h, and separate after heating Solid product; after natural cooling, wash and dry to obtain nano-copper ferrite oxygen carrier.

[0041] The oxygen carrier particles prepared above were sieved, and 0.2 g of the oxygen carrier with a particle size of 100-150 mesh was taken for performance testing in a small quartz fluidized bed. The composition of the gaseo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com