A method for preparing flaky alumina powder

A technology of flake alumina and aluminum hydroxide, which is applied in the direction of alumina/aluminum hydroxide, can solve the problems of small average diameter and thickness of flake powder, insignificant flake characteristics, and expensive raw materials, so as to reduce the calcination temperature , Improve the chemical reaction rate, increase the effect of reactant concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

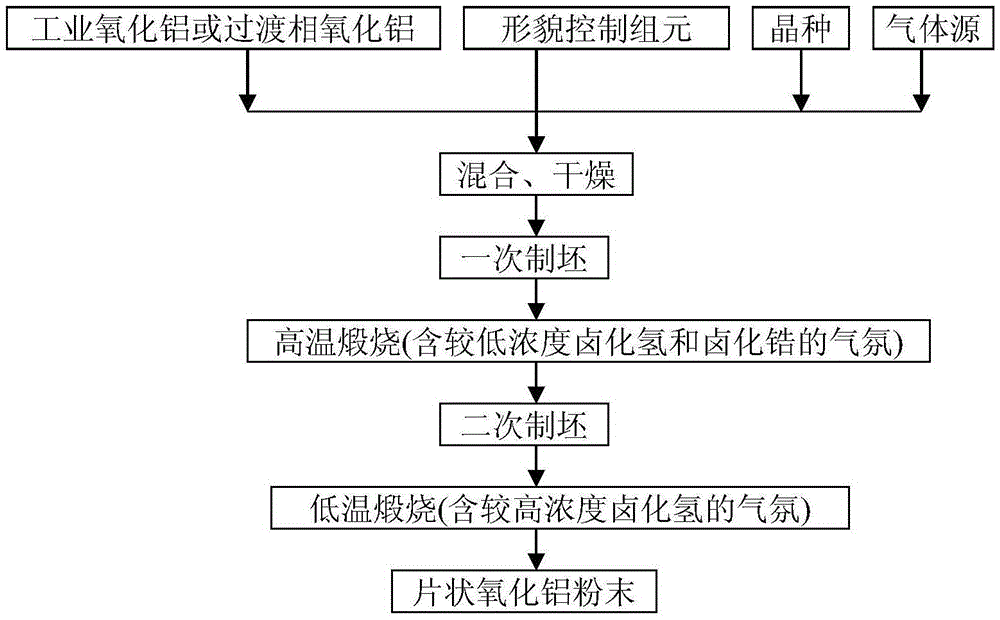

Method used

Image

Examples

Embodiment 1

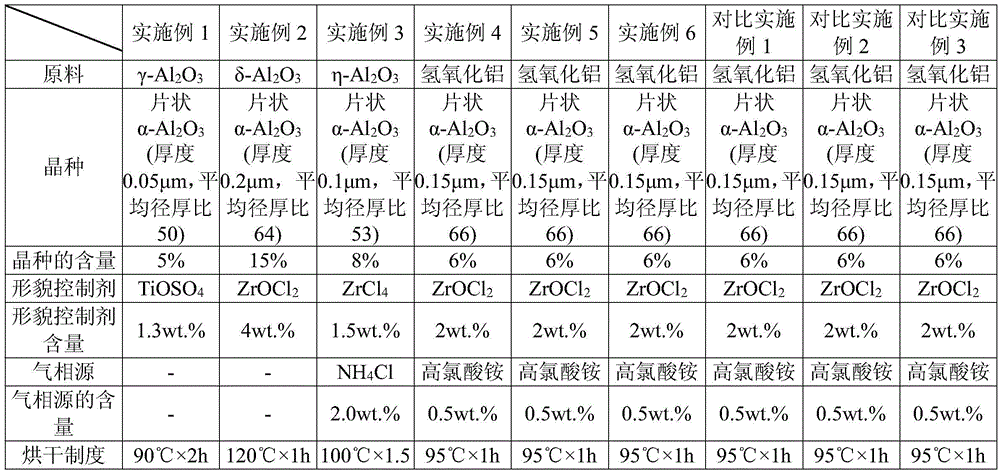

[0023] Example 1: with γ-Al 2 o 3 and TiOSO 4 Preparation of flaky alumina powder as raw material

[0024] γ-Al 2 o 3 Powder is the raw material, add 5wt.% flake α-Al to the raw material powder 2 o 3 Seed (thickness 0.05μm, average aspect ratio 50) and 1.3wt.% morphology inhibitor (TiOSO 4 ), mixed evenly by means of stirring or ball milling, and then dried at 90°C for 2 hours to obtain a mixture. Add 1wt.% dextrin or polyvinyl alcohol to the dried mixture, and shape it under the pressure of 200MPa to obtain a primary green body; the primary green body is calcined at a high temperature at 1000°C for 8 hours. The concentration of hydrogen fluoride in the primary calcination atmosphere is 0.1%, the concentration of ammonia is 0.1%, the concentration of zirconium chloride is 1%, the concentration of hydrogen is 1%, the concentration of nitrogen is 2%, and the balance is air. After the primary calcination, the primary calcined green body is obtained; the primary calcined g...

Embodiment 2

[0025] Example 2: with γ-Al 2 o 3 and ZrOCl 2 Preparation of flaky alumina powder as raw material

[0026] δ-Al 2 o 3 Powder is the raw material, and 15wt.% seed crystal (thickness 0.2μm, average aspect ratio 64) and 4wt.% morphology inhibitor (ZrOCl 2), mixed evenly by means of stirring or ball milling, and then dried at 120° C. for 1 hour to obtain a mixture. Add 0.5wt.% dextrin or polyvinyl alcohol to the dried mixture and shape it under a pressure of 250MPa to obtain a primary green body; the primary green body is calcined at a high temperature at 1150°C for 8 hours . The concentration of hydrogen fluoride in the primary calcination atmosphere is 1.5%, the concentration of ammonia is 1.0%, the concentration of zirconium chloride is 4.0%, the concentration of hydrogen is 2.6%, the concentration of nitrogen is 5%, and the balance is air. After the primary calcination, the primary calcined green body is obtained; the primary calcined green body is broken into powder, a...

Embodiment 3

[0027] Embodiment 3: with η-Al 2 o 3 and ZrCl 4 Preparation of flaky alumina powder as raw material

[0028] η-Al 2 o 3 Powder is used as raw material, 8wt.% seed crystal (thickness 0.1μm, average aspect ratio 53), 1.5wt.% morphology inhibitor (ZrCl 4 ), 2.0wt.% gas source (NH 4 Cl), mixed uniformly by means of stirring or ball milling, and then dried at 100° C. for 1.5 hours to obtain a mixture. Add 1wt.% dextrin to the dried mixture and shape it under the pressure of 550MPa to obtain a primary green body; the primary green body is calcined at a high temperature at 1100°C for 2 hours. The concentration of hydrogen iodide in the primary calcination atmosphere is 1.2%, the concentration of ammonia gas is 0.5%, the concentration of zirconium fluoride is 3.5%, the concentration of hydrogen gas is 1.5%, the concentration of nitrogen gas is 4.5%, and the balance is air. After the primary calcination, the primary calcined green body is obtained; the primary calcined green bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com