A method for preparing flaky silicon dioxide powder

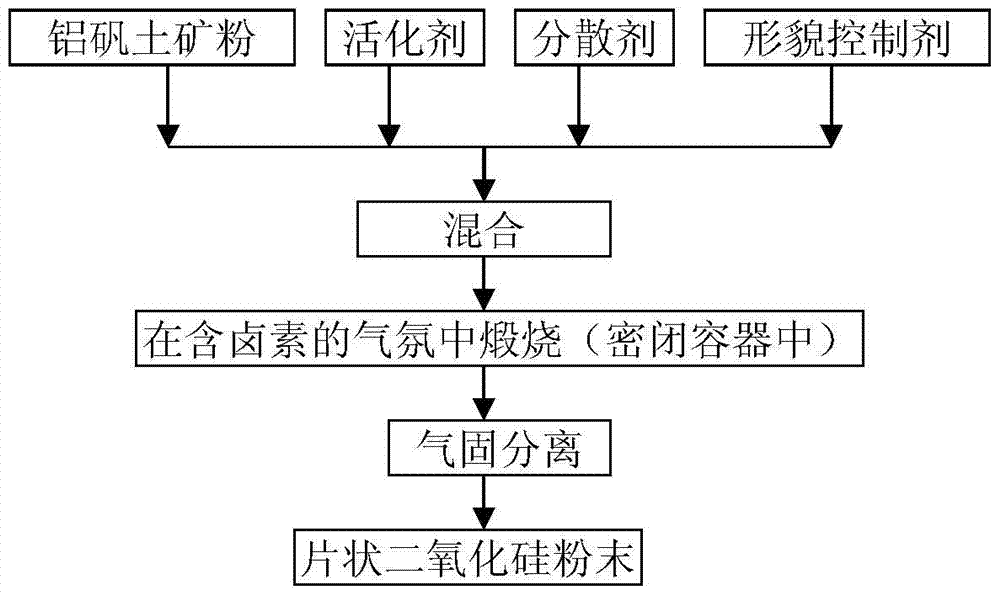

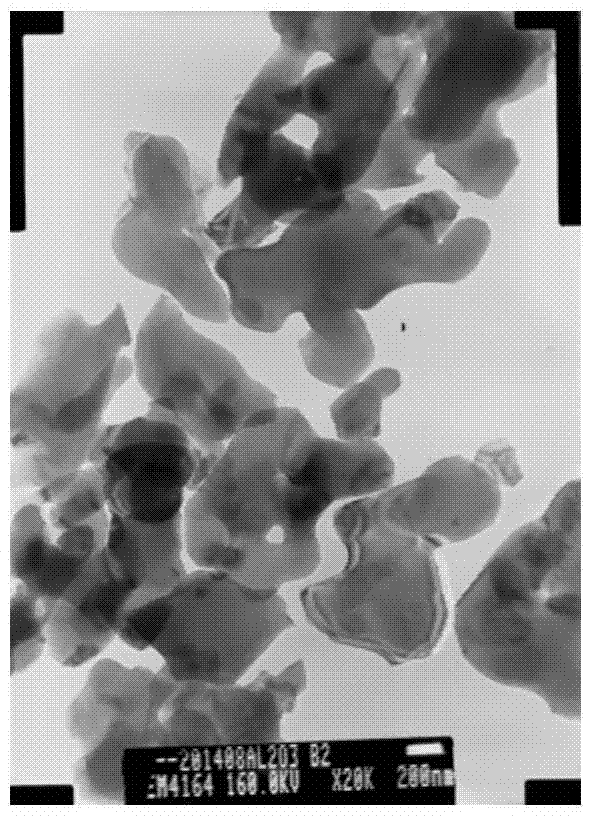

A silicon dioxide and powder technology, applied in the field of preparing flake silicon dioxide powder, can solve the problems of small average diameter and thickness of flake powder, difficulty in large-scale production, insignificant flake characteristics, etc., and achieves regular crystal morphology, The effect of perfect grain development and adjustable diameter-thickness ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: with NH 4 NO 3 , phosphorus pentachloride and aluminum difluoride as additives to prepare flaky silica powder

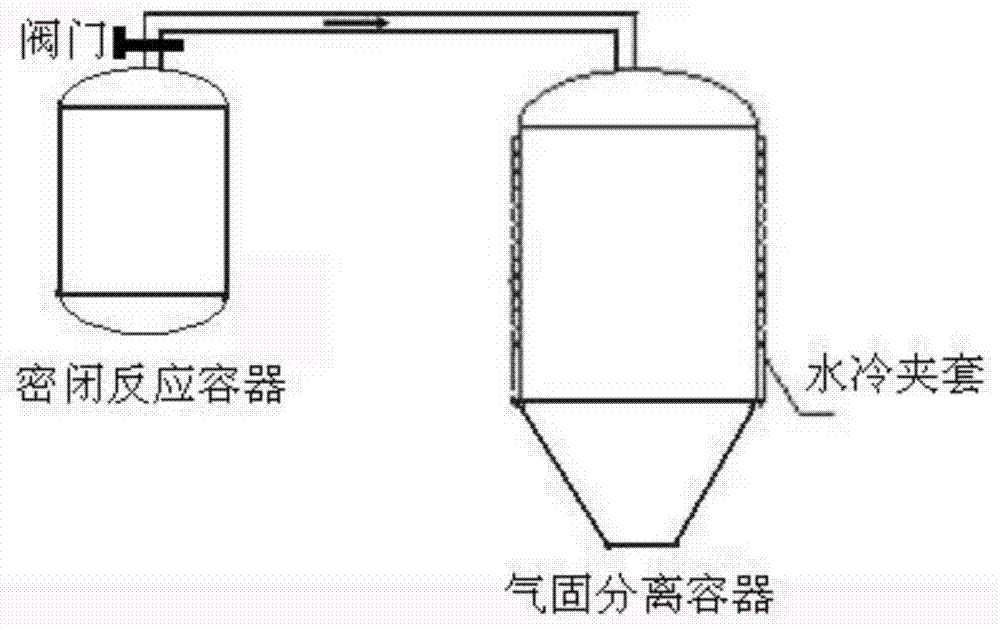

[0027] with SiO 2 The bauxite ore is used as a raw material, and the bauxite ore is dried at 300 ° C for 1 hour, and the bauxite ore is crushed into a powder with a particle size of 0.1mm, and 0.05wt.% NH is added to the bauxite ore powder 4 NO 3 , 1wt.% phosphorus pentachloride and 6wt.% aluminum difluoride are uniformly mixed by means of stirring or ball milling to obtain a mixed powder. The mixed powder is packed in an airtight container, and the volume of the mixed powder accounts for 40% of the volume of the airtight container. The calcination is carried out in an atmosphere containing halogen, the calcination temperature is 600° C., the atmosphere pressure is 0.1 MPa, and the calcination time is 2 hours. During the calcination process, the formed silicon halide is hydrolyzed to obtain silicon dioxide and hydrogen halide. The atmosphere c...

Embodiment 2

[0028] Embodiment 2: Preparation of flaky silica powder with ammonium sulfate, phosphorus trifluoride and ferric fluoride as additives

[0029] with SiO 2 The zircon sand is used as a raw material, and the zircon sand is dried at 400°C for 2 hours, and the zircon sand is broken into a powder with a particle size of 0.3mm, and 0.08wt.% ammonium sulfate, 0.8wt.% ammonium sulfate and 0.8wt. % phosphorus trifluoride and 5wt.% ferric fluoride are uniformly mixed by means of stirring or ball milling to obtain a mixed powder. The mixed powder is packed in an airtight container, and the volume of the mixed powder accounts for 50% of the volume of the airtight container. The calcination is carried out in an atmosphere containing halogen, the calcination temperature is 1100° C., the atmospheric pressure is 0.2 MPa, and the calcination time is 6 hours. During the calcination process, the formed silicon halide is hydrolyzed to obtain silicon dioxide and hydrogen halide. The atmosphere ...

Embodiment 3

[0030] Example 3: Preparation of flaky silica powder with ammonium carbonate, phosphorus tribromide and niobium fluoride as additives

[0031] with SiO 2 The fly ash is used as raw material, and the fly ash is dried at 500°C for 3 hours, and the fly ash is broken into a powder with a particle size of 0.5mm. Add 0.06wt.% ammonium carbonate, 0.5wt.% Phosphorus tribromide and 4.5wt.% niobium fluoride are uniformly mixed by means of stirring or ball milling to obtain a mixed powder. The mixed powder is packed in an airtight container, and the volume of the mixed powder accounts for 60% of the volume of the airtight container. The calcination is carried out in an atmosphere containing halogen, the calcination temperature is 1200° C., the atmospheric pressure is 0.4 MPa, and the calcination time is 5 hours. During the calcination process, the formed silicon halide is hydrolyzed to obtain silicon dioxide and hydrogen halide. The atmosphere containing hydrogen halide is a mixed gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com