A composite material preparation system that effectively improves the interfacial bonding of composite materials

A composite material and interfacial combination technology, applied in chemical/physical/physicochemical processes of applied energy, chemical/physical/physicochemical fixed reactors, graphite, etc., can solve the problems of difficult industrial production, uneven distribution, Problems such as poor interface bonding, to achieve the effects of improving electromagnetic interference resistance, improving interface bonding, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Step 1: Dissolve 0.012mol of potassium permanganate in 30ml of distilled water, and stir magnetically for 30 minutes to obtain 0.4mol / L of potassium permanganate solution;

[0082] Step 2: Disperse 0.012 mol of phenylpropanal in 30 ml of distilled water, and stir magnetically for 30 minutes to obtain a 0.4 mol / L phenylpropanal solution;

[0083] Step 3: Mix the potassium permanganate solution and the phenylpropanal solution and then magnetically stir for 30 minutes to obtain the reaction precursor C;

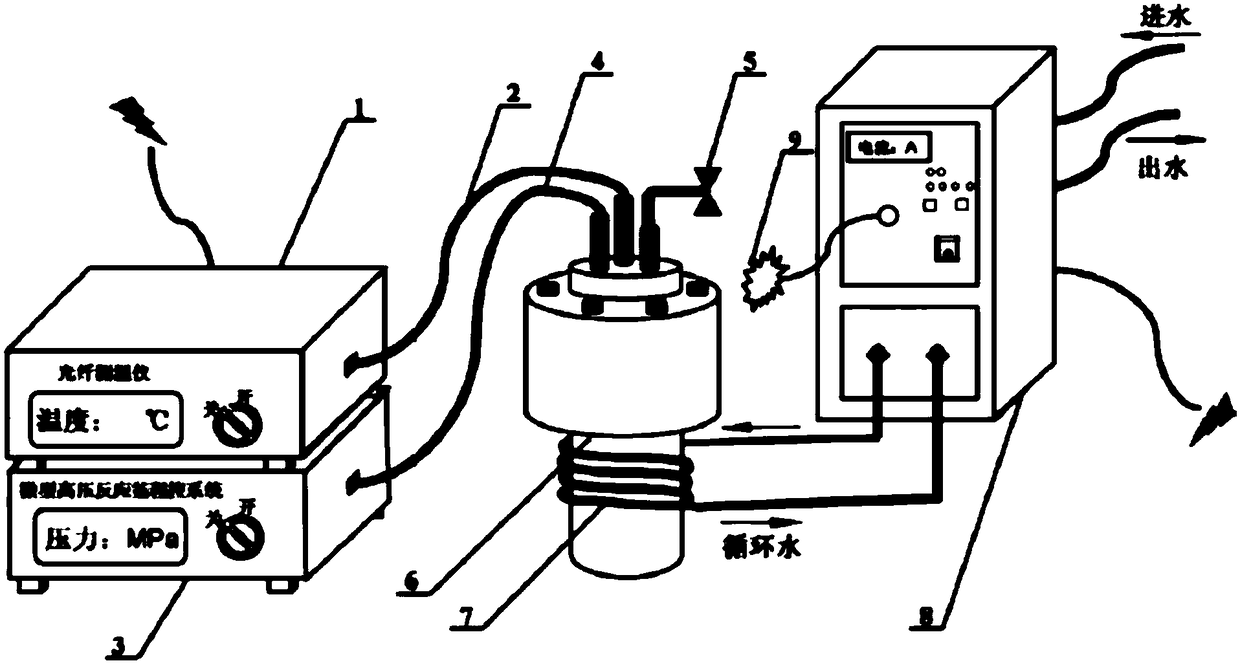

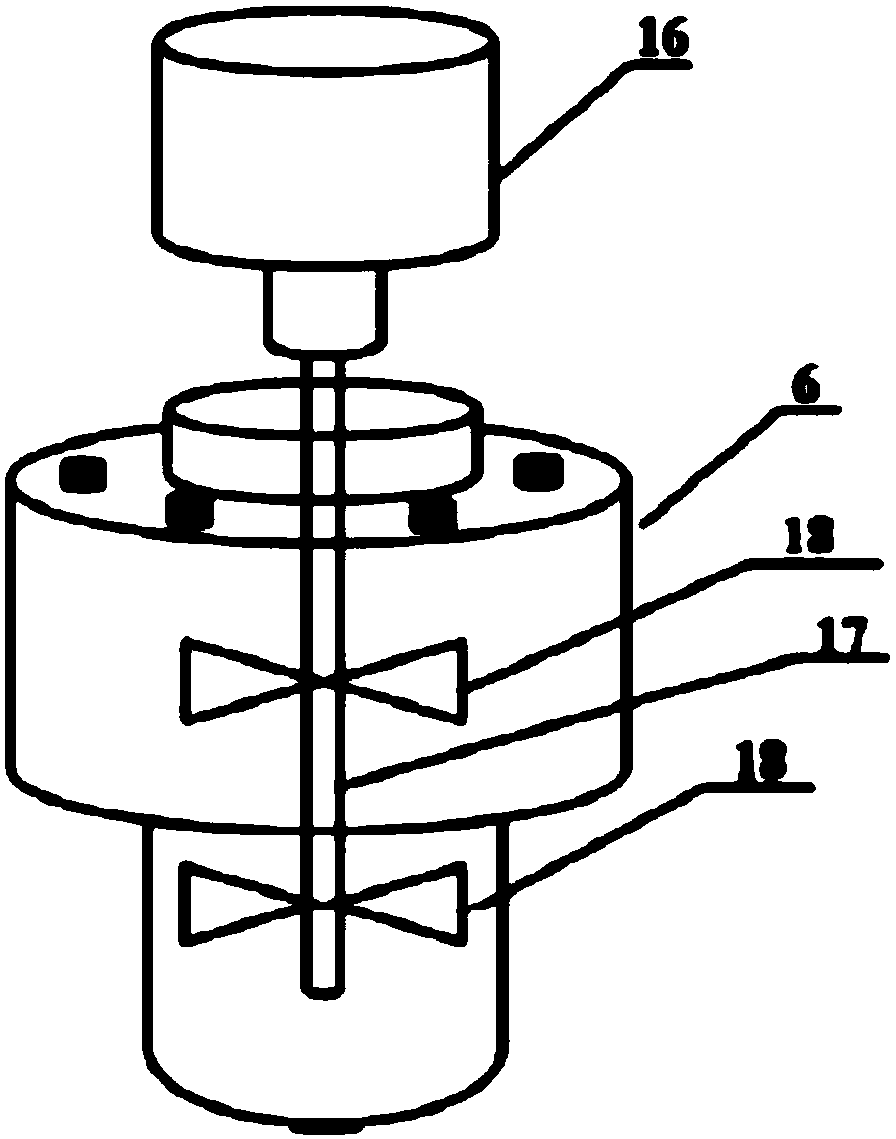

[0084] Step 4: Transfer the precursor solution C into the reaction kettle, add a graphite sheet capable of inducing an alternating magnetic field, seal it and place it in a hydrothermal induction heating device, react at an induction frequency of 50KHz and an output current of 200A for 24 hours, and then Natural cooling to room temperature;

[0085] Step 5: Separate the composite product from the reacted suspension, soak and wash the product with deionized water and abso...

Embodiment 2

[0087] Step 1: Dissolve 0.015 mol of potassium permanganate in 30 ml of distilled water, and magnetically stir for 50 minutes to obtain 0.5 mol / L of potassium permanganate solution;

[0088] Step 2: Disperse 0.015 mol of phenylpropanal in 30 ml of distilled water, and stir magnetically for 50 minutes to obtain a 0.5 mol / L phenylpropanal solution;

[0089] Step 3: Mix the potassium permanganate solution and the phenylpropionaldehyde solution and then magnetically stir for 50 minutes to obtain the reaction precursor C;

[0090] Step 4: Transfer the precursor solution C into the reaction kettle, add a graphite sheet capable of inducing an alternating magnetic field, seal it and place it in a hydrothermal induction heating device, react at an induction frequency of 50KHz and an output current of 300A for 16 hours, and then Natural cooling to room temperature;

[0091] Step 5: Separate the complex product from the reacted suspension, soak and wash the product with deionized water ...

Embodiment 3

[0093] Step 1: Dissolve 0.02mol of potassium permanganate in 30ml of distilled water, and magnetically stir for 70 minutes to obtain 0.67mol / L of potassium permanganate solution;

[0094] Step 2: Disperse 0.02 mol of phenylpropanal in 30 ml of distilled water, and magnetically stir for 70 minutes to obtain a 0.67 mol / L phenylpropanal solution;

[0095] Step 3: Mix the potassium permanganate solution and the phenylpropionaldehyde solution and then magnetically stir for 70 minutes to obtain the reaction precursor C;

[0096] Step 4: Transfer the precursor solution C into the reaction kettle, add a graphite sheet capable of inducing an alternating magnetic field, seal it and place it in a hydrothermal induction heating device, react for 10 hours at an induction frequency of 50KHz and an output current of 400A, and then Natural cooling to room temperature;

[0097] Step 5: Separate the complex product from the reacted suspension, soak and wash the product with deionized water and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com