Bismuth ferrite catalyst and its preparation method and application

A bismuth ferrite and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that the charge mobility and photogenerated charges have not reached the ideal level, and achieve regular crystal morphology, Effect of high crystallinity and improved catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] [The preparation method of bismuth ferrite catalyst]

[0031] A first aspect of the present invention provides a kind of preparation method of bismuth ferrite catalyst, it comprises the following steps:

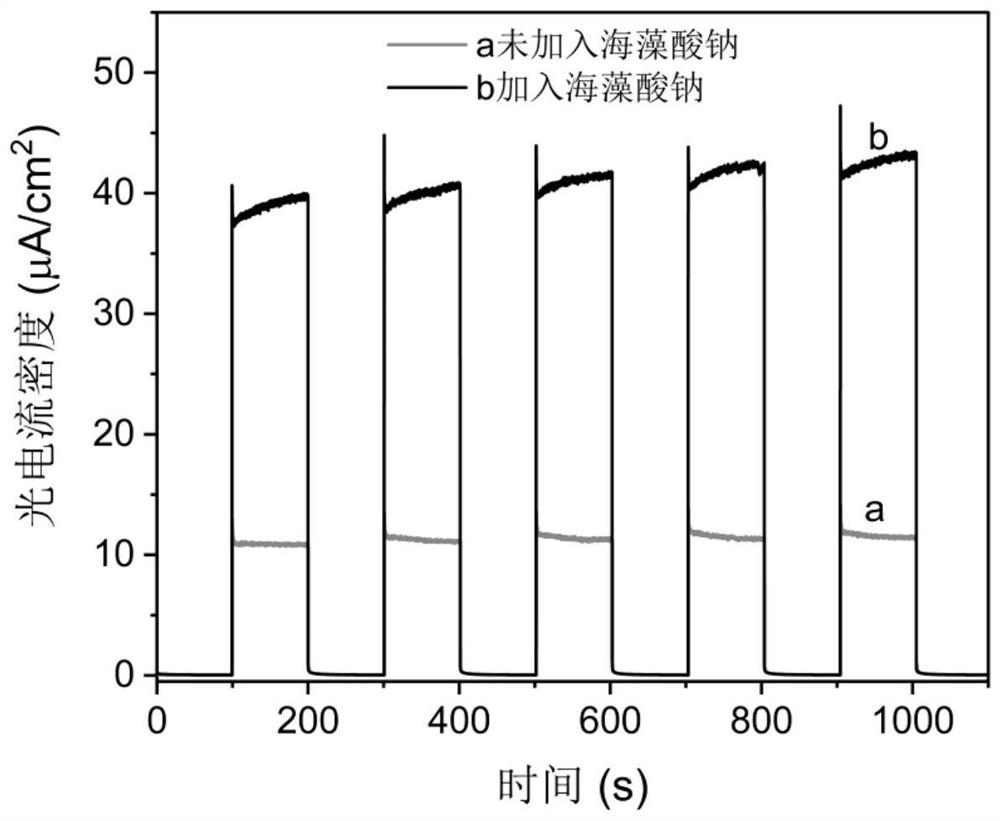

[0032] (1) The preparation step of the bismuth ferrite precursor, which comprises mixing the iron source and the sodium alginate aqueous solution, and adding the bismuth source, and stirring to obtain the bismuth ferrite precursor; and

[0033] (2) The preparation step of the bismuth ferrite catalyst, which comprises mixing the bismuth ferrite precursor with an alkaline solution, mixing and reacting at a temperature suitable for the reaction of the bismuth ferrite precursor and the alkaline solution to obtain ferric acid bismuth catalyst.

[0034] Step (1) is the preparation process of the bismuth ferrite catalyst precursor. Wherein, the iron source provides the iron element of the bismuth ferrite precursor, and the bismuth source provides the bismuth element of the ...

Embodiment

[0048] This embodiment is an exemplary method for preparing a bismuth ferrite catalyst, which includes the following steps:

[0049] (1) Preparation of bismuth ferrite precursor:

[0050] Dissolve 0.1g-0.5g sodium alginate in 20mL deionized water and stir well. Add 2-4mmol ferric chloride (or ferric sulfate, ferric nitrate, etc.) to the sodium alginate solution, stir well and then add 1-2mmol bismuth nitrate so that the molar ratio of bismuth to iron is 1:2. After stirring evenly, a brown precursor mixture was obtained.

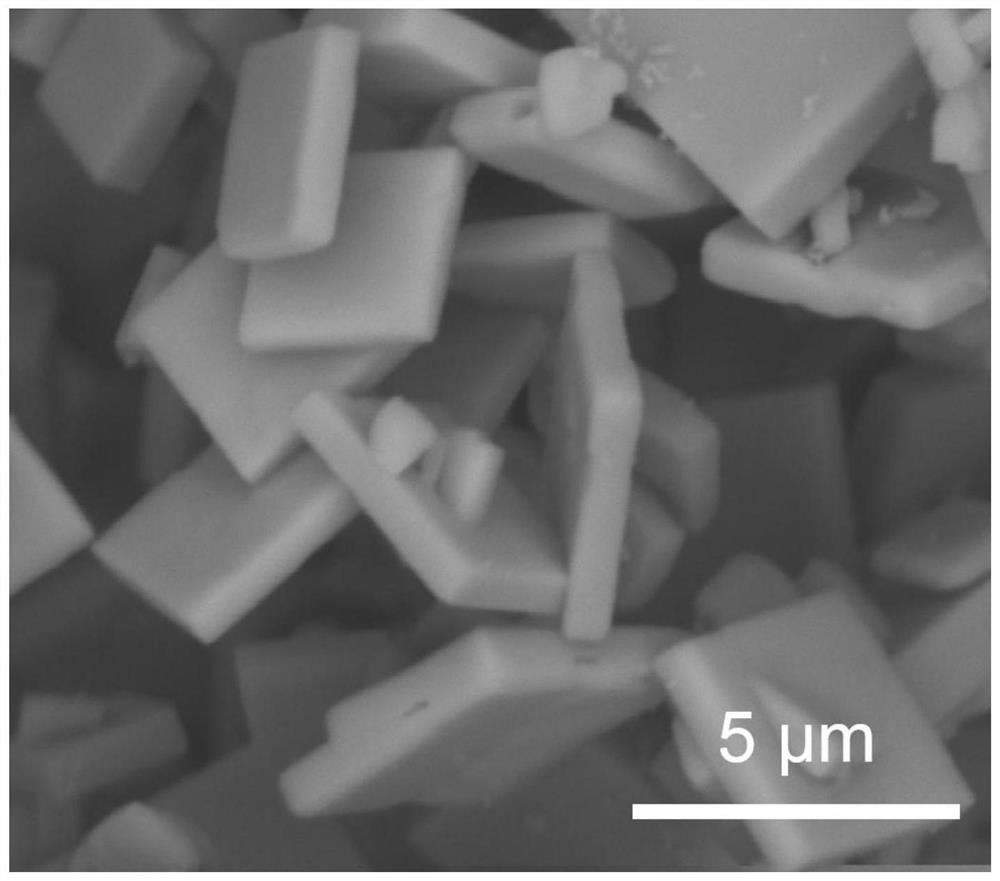

[0051] (2) Add 20 mL of 4-7 mol / L NaOH aqueous solution dropwise into the precursor mixture. After stirring evenly, transfer to a 100mL stainless steel reaction kettle, and heat at 200°C for 12-24 hours. After the obtained powder is fully washed, it is dried to prepare bismuth ferrite micro-sheets.

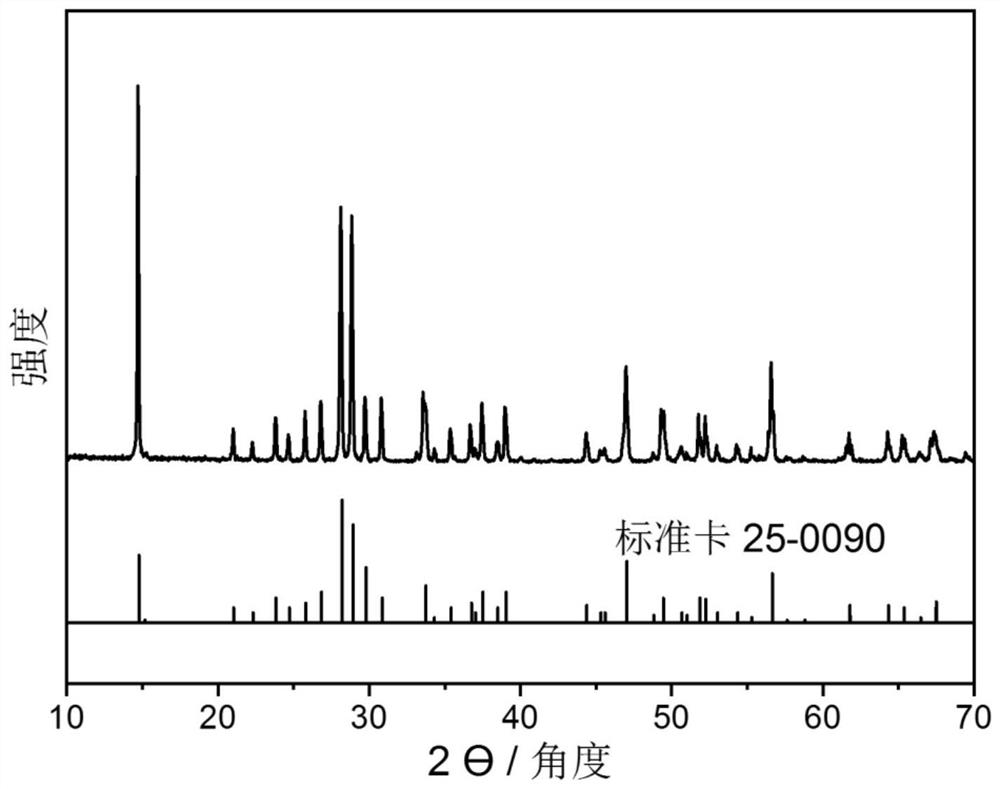

[0052] The X-ray diffraction pattern of the bismuth ferrite catalyst is as follows figure 1 As shown, according to the comparison with the standard card 25-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com