Preparation method of LiNixCoyMnl-x-yO2 cathode material for lithium ion battery

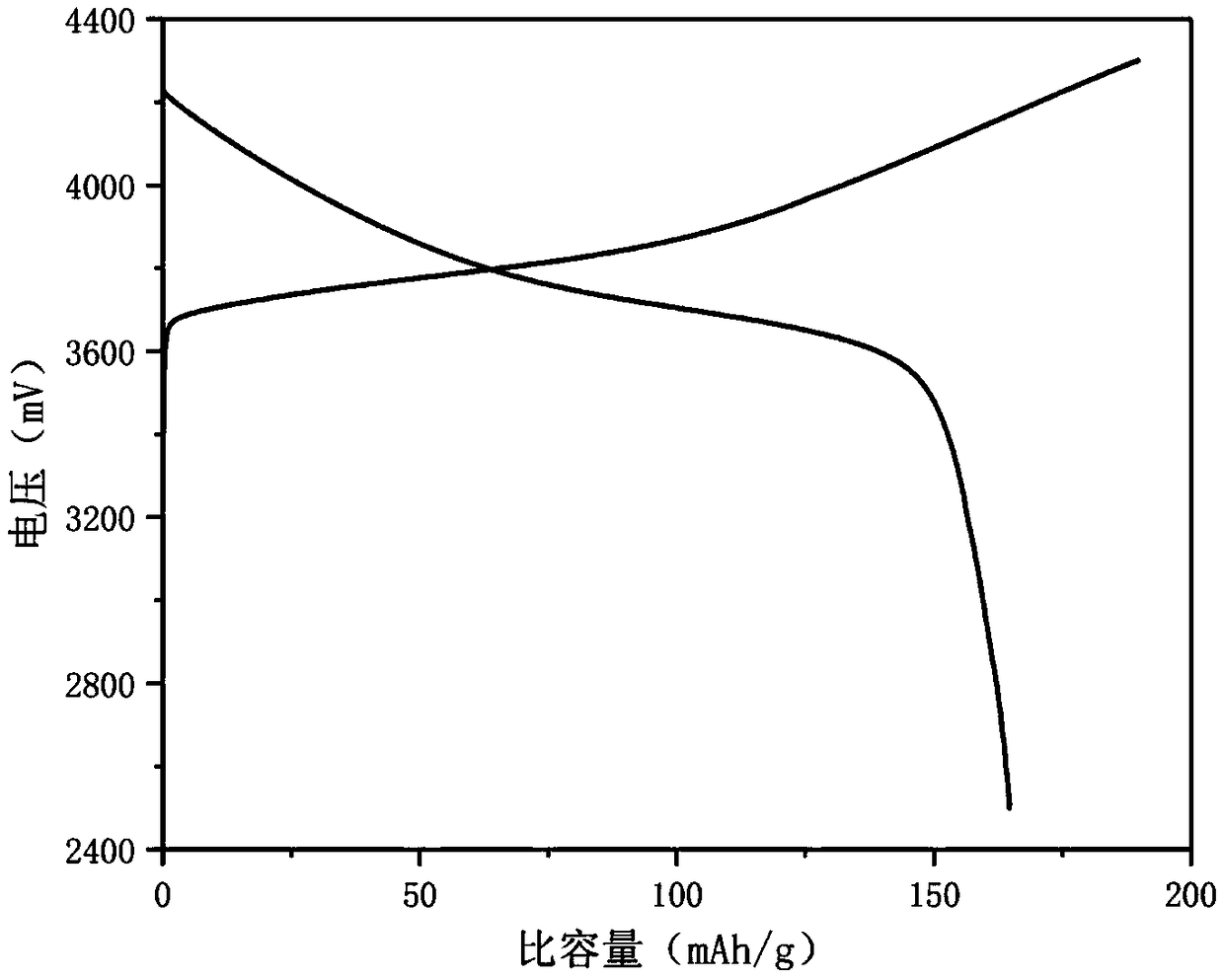

A technology for lithium ion batteries and positive electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of affecting the electrochemical performance of synthetic materials, affecting the rate performance of materials, and uneven precursor components, and achieving particle size. Small, high specific capacity, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

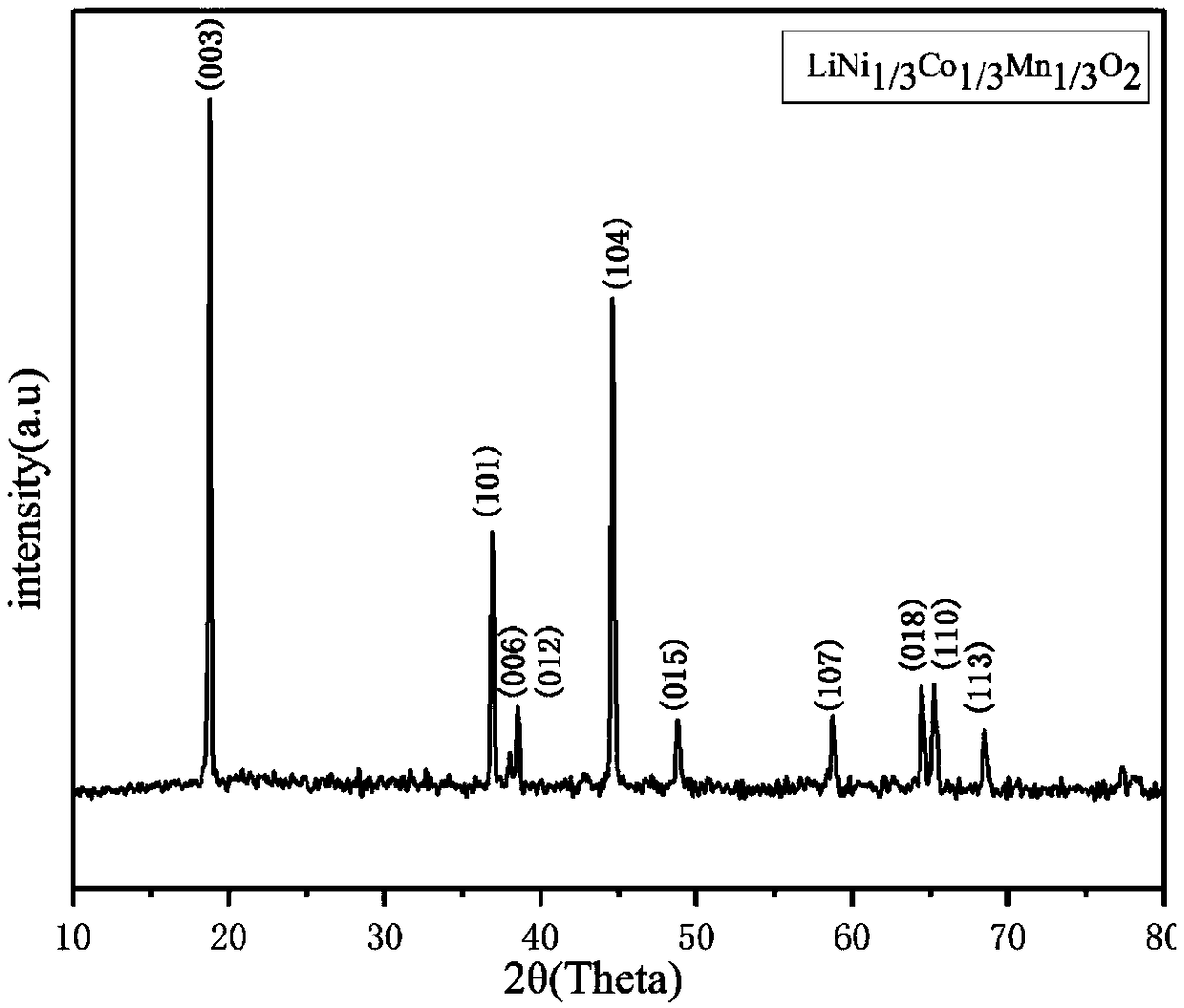

[0032] A lithium ion battery LiNi x co y mn l-x-y o 2 The preparation method of cathode material specifically comprises the following steps:

[0033](1) Dissolve 2.489g nickel acetate, 2.491g cobalt acetate, 2.451g manganese acetate, and 2.4g urea in a mixed solvent of ethanol and ethylene glycol. The volume ratio of ethanol and ethylene glycol is 2:1, and then carry out Stir magnetically for 6 hours at a stirring speed of 650 rpm / min to disperse the components in the mixed solvent evenly, then move the mixed solution to a stainless steel autoclave lined with polytetrafluoroethylene, react continuously at 140°C for 12 hours, and cool to After room temperature, wash several times with deionized water and absolute ethanol, centrifuge at 600rpm / min, dry at 110°C for 12h, and grind to obtain Ni 1 / 3 co 1 / 3 mn 1 / 3 CO 3 Precursor;

[0034] (2), the excess LiOH and Ni 1 / 3 co 1 / 3 mn 1 / 3 CO 3 The precursor was added to absolute ethanol to disperse evenly, dried and ground, t...

Embodiment 2

[0039] (1) Dissolve 2.489g of nickel acetate, 2.491g of cobalt acetate, 2.451g of manganese acetate, and 2.4g of urea in a mixed solvent of deionized water and ethylene glycol. The volume ratio of deionized water and ethylene glycol is 2: 1. Then perform magnetic stirring for 6 hours at a stirring speed of 650rpm / min to disperse the components in the mixed solvent evenly, then move the mixed solution to a stainless steel autoclave lined with polytetrafluoroethylene, and react continuously at 140°C After cooling to room temperature for 12 hours, wash with deionized water and absolute ethanol several times, centrifuge at 600 rpm / min, dry at 110°C for 12 hours, and grind to obtain Ni 1 / 3 co 1 / 3 mn 1 / 3 CO 3 Precursor;

[0040] (2), the excess LiOH and Ni 1 / 3 co 1 / 3 mn 1 / 3 CO 3 The precursor was added to absolute ethanol to disperse evenly, dried and ground, then placed in a muffle furnace, the temperature was raised to 550°C at a rate of 4°C / min, kept for 4 hours, then rais...

Embodiment 3

[0045] A lithium ion battery LiNi x co y mn l-x-y o 2 The preparation method of cathode material specifically comprises the following steps:

[0046] (1) Dissolve 2.489g nickel acetate, 2.491g cobalt acetate, 2.451g manganese acetate, and 2.4g urea in a mixed solvent of deionized water and ethylene glycol. The volume ratio of deionized water and ethylene glycol is 2:1 , then carry out magnetic stirring for 6h, the stirring speed is 650rpm / min, so that the components in the mixed solvent are uniformly dispersed, and then the mixed solution is moved to a stainless steel autoclave with a polytetrafluoroethylene liner, and the reaction is continued at 160°C for 10h , cooled to room temperature, washed several times with deionized water and absolute ethanol, centrifuged at 600rpm / min, dried at 110°C for 12h, and ground to obtain Ni 1 / 3 co 1 / 3 mn 1 / 3 CO 3 Precursor;

[0047] (2), the excess LiOH and Ni 1 / 3 co 1 / 3 mn 1 / 3 CO 3 The precursor was added to absolute ethanol to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com