Low-hexavalent-chromium precipitated copper and chromium black pigment as well as preparation method and application thereof

A technology of copper chrome black and hexavalent chromium is applied in the field of low hexavalent chromium precipitation copper chrome black pigment and its preparation, and can solve the problems of chemical stability, insufficient acid and alkali resistance and heat resistance, inability to black pigment, poor covering power, etc. problem, to achieve the effect of complete grain, good dispersion and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

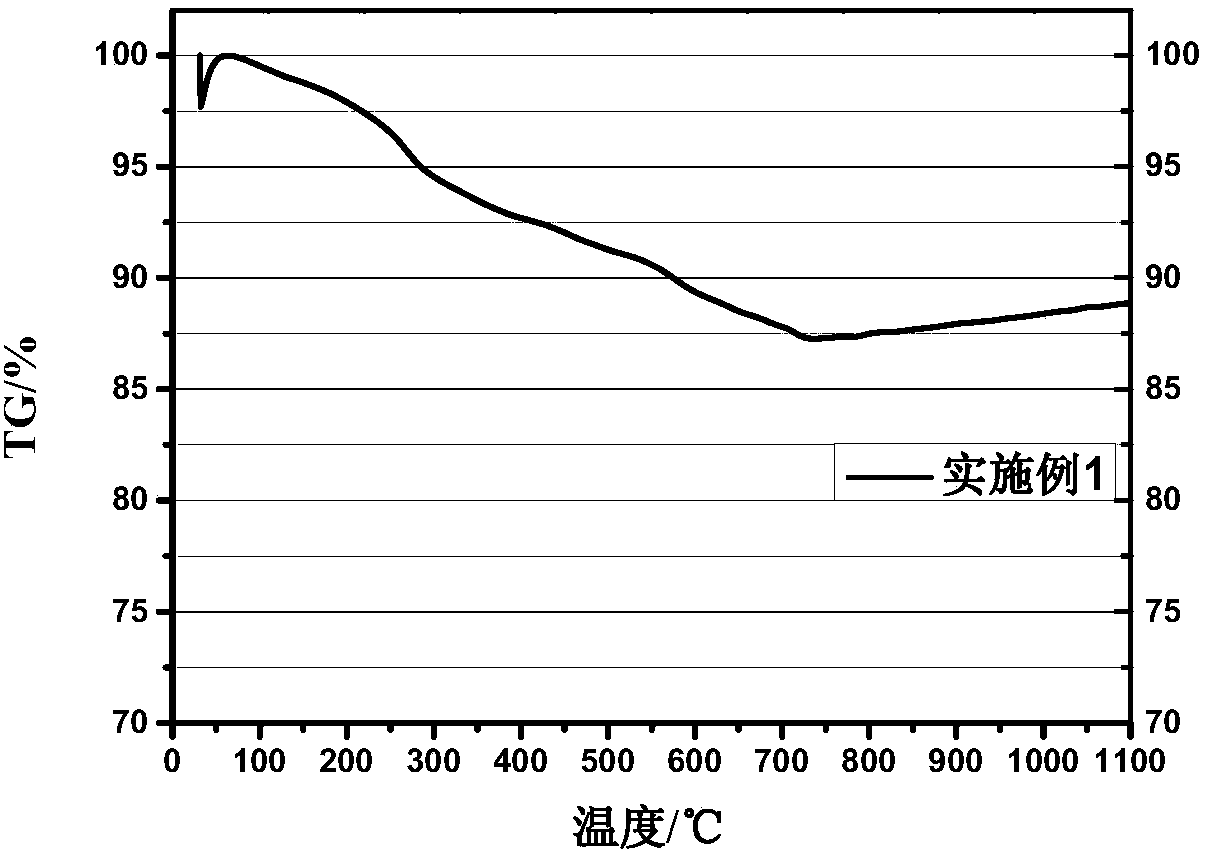

Embodiment 1

[0054] A low hexavalent chromium precipitated copper chromium black pigment is composed of Cu and Cr elements, Cu:Cr is 1:2, and the preparation method comprises the following steps:

[0055] (1) Preparation of nitrate solution: In order to reduce costs, copper oxide and chromium hydroxide are selected as raw materials, and 1.0mol CuO and 2.0mol Cr(OH) are taken 3 Add to 1.5kg deionized water, add 815g (theoretical dosage is 8molHNO 3 , add 1.1 times of theoretical consumption and convert into 68% industrial nitric acid mass) industrial nitric acid dissolution raw material with a mass fraction of 68%, the solution is stirred and heated, the heating temperature is 50 ° C, after the dissolution is completed, filter and remove insoluble impurity particles to obtain a nitrate solution ;

[0056] (2) Combustion solution preparation: add auxiliary fuel (200g citric acid monohydrate and 280g urea) to the nitrate solution in the step (1), continue heating and stirring at 50°C, and ob...

Embodiment 2

[0066] A low hexavalent chromium precipitated copper chromium black pigment is composed of Cu and Cr elements, and Cu:Cr is 1.1:2. The preparation method comprises the following steps:

[0067] (1) Preparation of nitrate solution: selected copper nitrate and chromium nitrate as raw materials, got 1.0molCu(NO 3 ) 2 ·3H 2 O and 2.0mol Cr(NO 3 ) 3 9H 2 O was added to 2.4kg deionized water, the solution was stirred and heated, the heating temperature was 60°C, after the dissolution was completed, the insoluble impurity particles were removed by filtration to obtain a nitrate solution;

[0068] (2) Combustion solution preparation: add auxiliary fuel (220g citric acid monohydrate, 300g urea) to the nitrate solution in the step (1), continue heating and stirring at 60°C, and obtain a combustion solution after dissolving;

[0069] (3) Low-temperature self-propagating combustion: The combustion solution in step (2) is evaporated and concentrated by heating at 60°C. After the volum...

Embodiment 3

[0075] A low hexavalent chromium precipitated copper chromium black pigment is composed of Cu, Cr and Fe elements, Cu:Cr:Fe is 1.1:1.99:0.01, and the preparation method comprises the following steps:

[0076] (1) Preparation of nitrate solution: select copper oxide, chromium hydroxide, and ferric nitrate as raw materials, take 1.1mol CuO, 1.99mol Cr(OH) 3 , 0.01mol Fe(NO 3 ) 3 9H 2 O was added to 2.0kg deionized water, and 910g (theoretical dosage was 8.17molHNO 3 , add 1.2 times the theoretical amount and convert it into 68% industrial nitric acid (mass fraction of 68% industrial nitric acid) to dissolve the raw material, stir and heat the solution, the heating temperature is 70 ° C, after the dissolution is completed, filter and remove the insoluble impurity particles to obtain the nitrate solution ;

[0077] (2) Combustion solution preparation: add auxiliary fuel (220g citric acid monohydrate, 300g urea) to the nitrate solution in the step (1), continue heating and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com