A kind of microwave hydrothermal method prepares the method for cualo2 thin film

A microwave hydrothermal method and thin film technology, which is applied in the field of preparing CuAlO2 thin films by microwave hydrothermal method, can solve the problems of high equipment requirements, complex process, poor repeatability, etc., and achieve the effects of low preparation cost, uniform particle size distribution and controllable shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

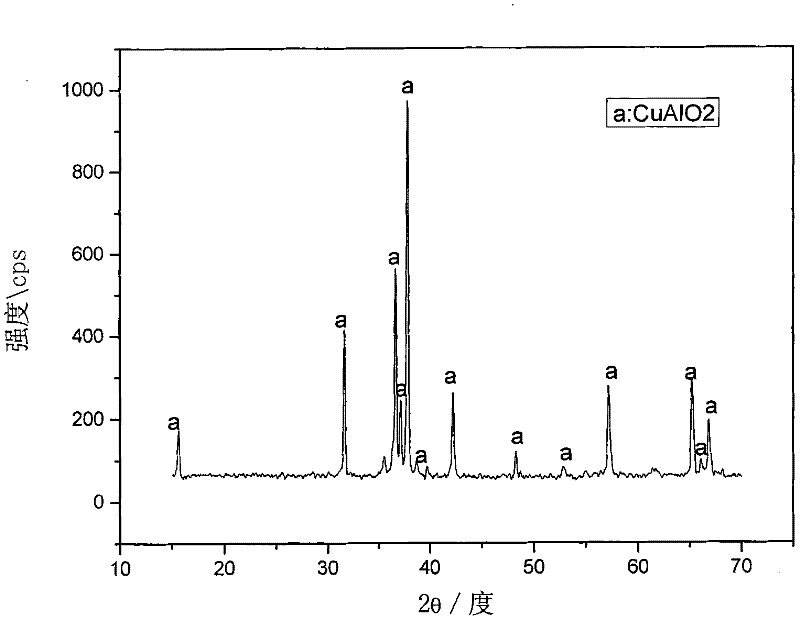

Image

Examples

Embodiment 1

[0014] Step 1: First, add analytically pure copper acetate monohydrate to ethylene glycol to prepare Cu 2+ A blue transparent solution with a concentration of 0.1mol / L, the resulting solution is denoted as A;

[0015] Step 2: then add analytically pure aluminum nitrate nonahydrate in the A solution, so that (Cu 2+ ): (Al 3+ )=1:1 molar ratio, and constantly stirring, while adding the HCOOH reagent with a molar fraction of 0.5%, adjusting the pH value to 2.0 under stirring to form a uniform precursor solution B;

[0016] Step 3: Soak the silicon substrate in HF solution with a volume concentration of 20% for 5 minutes, clean it with deionized water, and then perform ultrasonic cleaning with ethanol solution, then pour solution B into a hydrothermal reaction kettle, and the filling degree is controlled At 60%; place the silicon substrate after ultrasonic cleaning in the hydrothermal reaction kettle and immerse it in the B solution; then seal the hydrothermal reaction kettle an...

Embodiment 2

[0019] Step 1: First, add analytically pure copper acetate monohydrate to ethylene glycol to prepare Cu 2+ Concentration is the blue transparent solution of 0.2mol / L, and the obtained solution is recorded as A;

[0020] Step 2: then add analytically pure aluminum nitrate nonahydrate in the A solution, so that (Cu 2+ ): (Al 3+ )=1:1 molar ratio, and constantly stirring, while adding the HCOOH reagent with a molar fraction of 0.6%, adjusting the pH value to 3.0 under stirring to form a uniform precursor solution B;

[0021] Step 3: Soak the silicon substrate in HF solution with a volume concentration of 20% for 5 minutes, clean it with deionized water, and then perform ultrasonic cleaning with ethanol solution, then pour solution B into a hydrothermal reaction kettle, and the filling degree is controlled At 50%; place the silicon substrate after ultrasonic cleaning in the hydrothermal reaction kettle and immerse it in the B solution; then seal the hydrothermal reaction kettle ...

Embodiment 3

[0024] Step 1: First, add analytically pure copper acetate monohydrate to ethylene glycol to prepare Cu 2+ Concentration is the blue transparent solution of 0.4mol / L, and the obtained solution is recorded as A;

[0025] Step 2: then add analytically pure aluminum nitrate nonahydrate in the A solution, so that (Cu 2+ ): (Al 3+ )=1:1 molar ratio, and constantly stirring, while adding the HCOOH reagent with a molar fraction of 0.8%, adjusting the pH value to 4.0 under stirring to form a uniform precursor solution B;

[0026] Step 3: Soak the silicon substrate in HF solution with a volume concentration of 20% for 5 minutes, clean it with deionized water, and then perform ultrasonic cleaning with ethanol solution, then pour solution B into a hydrothermal reaction kettle, and the filling degree is controlled At 70%; place the silicon substrate after ultrasonic cleaning in a hydrothermal reaction kettle and immerse it in solution B; then seal the hydrothermal reaction kettle and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com