Lead-free piezoceramic material with manganese doping with bismuth titanate sodium group and preparation method thereof

A sodium bismuth titanate-based, lead-free piezoelectric technology is applied in the field of functional ceramics, which can solve the problems of limited development and achieve the effect of good microstructure and complete grain development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

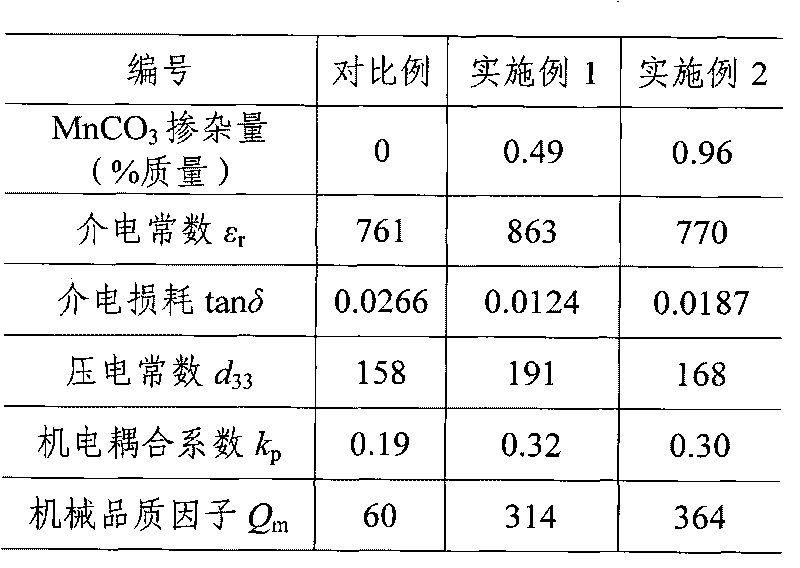

[0018] (1) Adopt anhydrous sodium carbonate, anhydrous potassium carbonate, bismuth oxide, titanium dioxide, barium carbonate and manganese carbonate, press 83.95Wt% Bi 1 / 2 Na 1 / 2 TiO 3 , 12.30Wt%Bi 1 / 2 K 1 / 2 TiO 3 , 3.26Wt% BaTiO 3 , 0.49 wt% MnCO 3 Prepare raw materials;

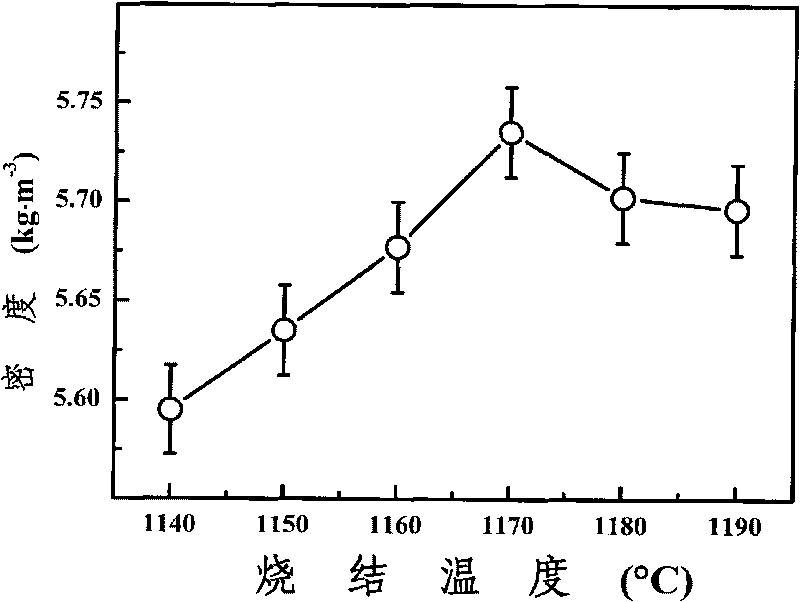

[0019] (2) The powder is compressed into blocks at 40 MPa, and the pre-synthesis temperature is 850° C., and the temperature is kept for 1 hour. The sintering temperature is 1170°C, and the holding time is 2 hours.

[0020] Other conditions are the same as the comparison

Embodiment 2

[0022] (1) Adopt anhydrous sodium carbonate, anhydrous potassium carbonate, bismuth oxide, titanium dioxide, barium carbonate and manganese carbonate, press 83.55Wt% Bi 1 / 2 Na 1 / 2 TiO 3 , 12.24Wt%Bi 1 / 2 K 1 / 2 TiO 3 , 3.25wt% BaTiO 3 and 0.96Wt% MnCO 3 With raw materials

[0023] (2) The powder is pressed into blocks at 30MPa, the pre-synthesis temperature is 800°C, and the temperature is kept for 1 hour. The sintering temperature is 1150°C, and the holding time is 2 hours.

[0024] Other conditions are the same as the comparison example.

[0025] Table 1 is the performance contrast table of the ceramic sample prepared by comparative example, embodiment 1 and 2

[0026]

[0027] The test conditions are as follows:

[0028] The bulk density is measured by the Metler XS104 precision electronic balance according to the Archimedes drainage method;

[0029] Dielectric constant and dielectric loss: Use the Agilent E4980 precision LCR meter to measure capacitance and die...

Embodiment 3

[0034] (1) Adopt anhydrous sodium carbonate, anhydrous potassium carbonate, bismuth oxide, titanium dioxide, barium carbonate and manganese carbonate, press 80.15Wt% Bi 1 / 2 Na 1 / 2 TiO 3 , 13.19Wt%Bi 1 / 2 K 1 / 2 TiO3 , 5.38Wt% BaTiO 3 and 1.28Wt%MnCO 3 Prepare raw materials;

[0035] (2) The powder is pressed into blocks at 30MPa, the pre-synthesis temperature is 800°C, and the temperature is kept for 1 hour. The sintering temperature is 1180°C, and the holding time is 1 hour.

[0036] Other conditions are the same as the comparison example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com